Method for measuring iron content in steel slag

A method for measuring iron content, which is applied in the field of analysis and testing, can solve problems such as the difficulty of measuring total iron content, and achieve the effects of reliable technical support, reliable method, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

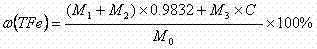

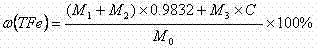

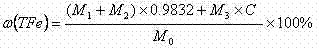

Image

Examples

Embodiment 1

[0032] A. After drying the steel slag sample to constant weight, process it with a crusher until the particle size is less than 5mm, and use a splitter to shrink it. Considering that the sample size must be representative and the volume of the grinding bowl should be taken into account, the sample is determined. Quantity (M 0 ) is 100g;

[0033] B, the 100g steel slag particles of step A are ground for 60 seconds, cross a 10 mesh sieve, grind the oversize for 90 seconds, cross a 10 mesh sieve; grind the oversize for 30 seconds, cross a 10 mesh sieve, combine the slag powder under the sieve, Weigh the sieve to get M 1 =42.17g;

[0034] C. Grind the under-sieve powder of step B for 60 seconds and pass through a 40-mesh sieve; grind the over-sieve for 90 seconds and pass through a 40-mesh sieve; then grind the over-sieve for 30 seconds, pass through a 40-mesh sieve, and combine the under-sieve slag Powder, weigh the sieve, get M 2 =6.73g;

[0035] D, the slag powder under th...

Embodiment 2

[0050] A. After drying the steel slag sample to constant weight, process it with a crusher until the particle size is less than 5mm, and use a splitter to shrink it. Considering that the sample size must be representative and the volume of the grinding bowl should be taken into account, the sample is determined. Quantity (M 0 ) is 100g;

[0051] B, the 100g steel slag particles of step A are ground for 50 seconds, cross a 10 mesh sieve, grind the oversize for 100 seconds, cross a 10 mesh sieve; grind the oversize for 20 seconds, cross a 10 mesh sieve, and combine the slag powder under the sieve, Weigh the sieve to get M 1 =42.83g;

[0052] C. Grind the under-sieve slag powder of step B for 50 seconds and pass through a 40-mesh sieve; grind the over-sieve for 100 seconds and pass through a 40-mesh sieve; then grind the over-sieve for 20 seconds, pass through a 40-mesh sieve, and combine the under-sieve slag Powder, weigh the sieve, get M 2 =7.16g;

[0053] D, the slag powd...

Embodiment 3

[0068] A. After drying the steel slag sample to constant weight, process it with a crusher until the particle size is less than 5mm, and use a splitter to shrink it. Considering that the sample size must be representative and the volume of the grinding bowl should be taken into account, the sample is determined. Quantity (M 0 ) is 100g;

[0069] B, the 100g steel slag particles of step A are ground for 70 seconds, cross a 10 mesh sieve, grind the oversize for 90 seconds, cross a 10 mesh sieve; grind the oversize for 40 seconds, cross a 10 mesh sieve, and combine the slag powder under the sieve, Weigh the sieve to get M 1 =42.33g;

[0070] C. Grind the under-sieve slag powder of step B for 70 seconds and pass through a 40-mesh sieve; grind the over-sieve for 80 seconds and pass through a 40-mesh sieve; then grind the over-sieve for 40 seconds, pass through a 40-mesh sieve, and combine the under-sieve slag Powder, weigh the sieve, get M 2 =6.88g;

[0071] D, the slag powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com