Catalytic synthesis method for functional animal nutrition additive butyrin

A technology of butyric acid glyceride and nutritional additives, which is applied in the field of solid acid catalyzed synthesis of organic acids and polyols, can solve the problem of low yield of butyric acid mono-diglycerides, and achieve the effect of simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: General synthesis method of butyric acid glyceride

[0028] General method for the synthesis of butyric acid glyceride (both tributyrin and mono- and diglyceride butyrate can be used): In a 250ml three-necked bottle with a water separator, reflux condenser and thermometer, add appropriate amount of glycerin, Butyric acid, sulfonic acid type strong acid ion exchange resin or carbon-based solid acid (the amount is 4.0% of the mass of glycerin) and toluene with water agent (25ml), stir, heat to reflux to bring out the water, heat to reflux the reaction system The temperature is maintained between 110~120℃. When the amount of water in the water trap reaches the theoretical amount and remains unchanged, stop heating, terminate the reaction, and filter out the sulfonic acid type strong acid ion exchange resin after cooling, the filtrate is decompressed to distill toluene with water, and it can be obtained after washing Target product. According to the molar ratio of...

Embodiment 2

[0029] Example 2: Synthesis of butyric acid monoglyceride

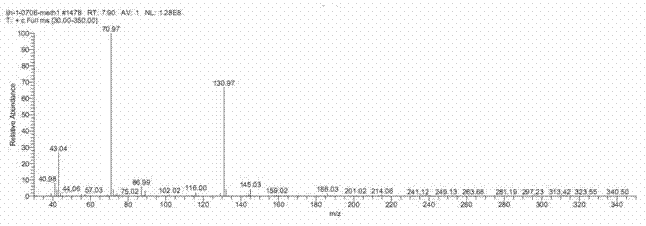

[0030] In a 250ml three-necked flask with water separator, reflux condenser and thermometer, add 18.4 grams (200mmol) of glycerin, 17.8 grams (200mmol) of n-butyric acid, and sulfonic acid type strong acid ion exchange resin (the amount is the quality of n-butyric acid 4.0%) and toluene (25ml) with water agent, stirring, heating and refluxing to bring out the generated water, heating and refluxing to keep the temperature of the reaction system at 115°C. When the amount of water in the water separator reaches about 3.6ml and remains unchanged, stop heating and terminate the reaction. After cooling, the catalyst sulfonic acid type strong acid ion exchange resin is filtered out. The filtrate is decompressed to distill the water-carrying toluene, which is washed with water. 30.2 grams of butyric acid monoglyceride based on butyric acid monoglyceride, the yield is 92.7%, such as figure 1 As shown, the content of butyric acid ...

Embodiment 3

[0031] Example 3: Synthesis of triglyceride butyrate

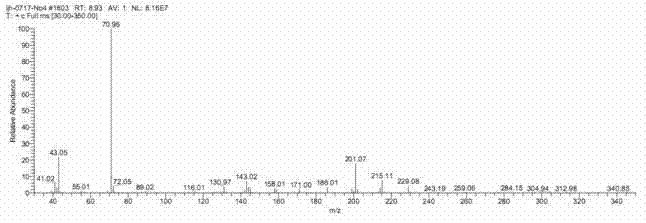

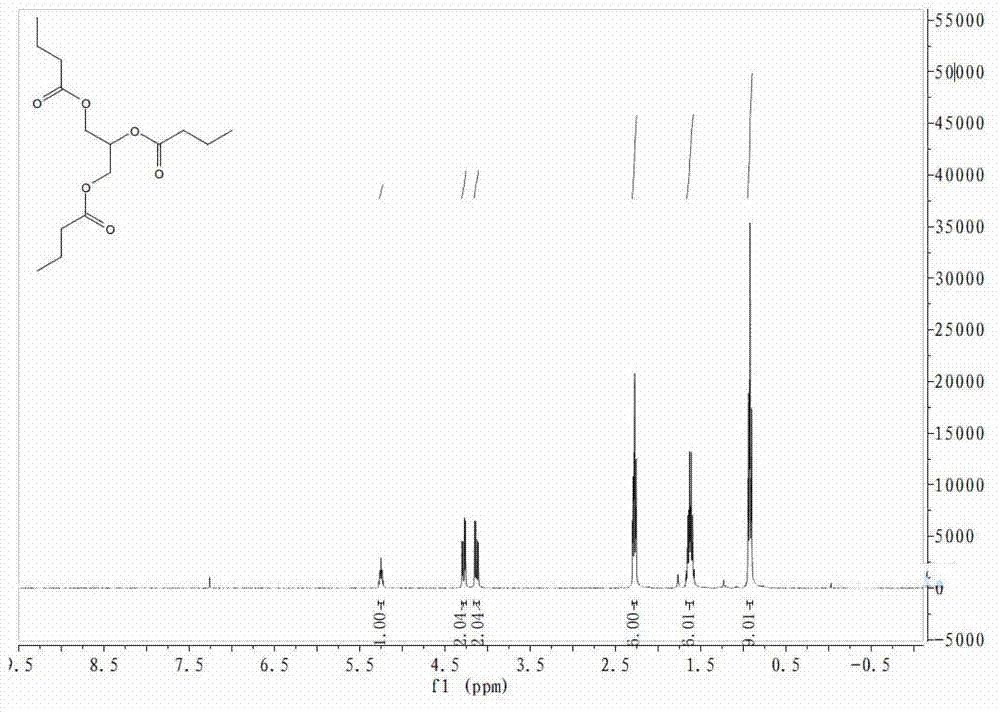

[0032] In a 250ml three-necked flask with water separator, reflux condenser and thermometer, add 18.4 grams (200mmol) of glycerin, 53.2 grams (600mmol) of n-butyric acid, and sulfonic acid type strong acid ion exchange resin (the amount is the quality of n-butyric acid 4.0%) and toluene (25ml) with water agent, stirring, heating and refluxing to bring out the generated water, heating and refluxing to keep the temperature of the reaction system at 115°C. When the amount of water in the water separator reaches about 11ml and remains unchanged, stop heating and terminate the reaction. After cooling, the catalyst sulfonic acid type strong acid ion exchange resin is filtered out, the filtrate is decompressed to distill toluene with water, and the target product is obtained after washing with water The butyrate triglyceride is 56.4 g, and the yield is 92.9%. Such as figure 2 with image 3 As shown, the content of triglyceride bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com