Preparation method for nanoscale alumina powder

An alumina powder and nano-scale technology is applied in the field of preparation of nano-scale alumina powder, which can solve the problem of high cost and achieve the effects of less impurity content, large pore volume and reasonable pore size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

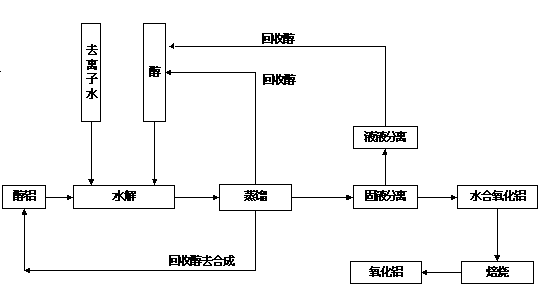

Method used

Image

Examples

Embodiment 1

[0034] Experimental material

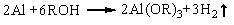

[0035] The selection of raw materials (such as type, purity, particle size, etc.) directly determines the gelling effect and the powder characteristics of nano-powders. Alcohol aluminum reaction preparation process conditions: 80-100 mesh aluminum powder 54g, catalyst / aluminum powder mass ratio=0.05, aluminum powder / n-hexanol molar ratio=1:4, reaction temperature: 160°C, operating pressure: ≤0.1 Mpa, reaction time: 2 hours, the reaction was carried out to obtain 616g of the intermediate product aluminum n-hexoxide.

[0036] Aluminum alkoxide compound hydrolysis reaction prepares nanoscale alumina powder process condition: the mol ratio of 616g n-hexyl aluminum and deionized water is 1:3, adds the surfactant polyethylene glycol 400 of 1% of n-hexyl aluminum weight, reaction temperature : 70°C, operating pressure: ≤0.1Mpa, pH value: 7.5, reaction time: 3 hours, after hydrolysis, distillation, and separation, 148g of hydrated alumina was obtained. ...

Embodiment 2

[0039] Alcohol aluminum reaction preparation process conditions: 100-200 mesh aluminum powder 54g, catalyst / aluminum powder mass ratio=0.03, aluminum powder / n-hexanol molar ratio=1:5, reaction temperature: 160°C, operating pressure: ≤0.15 Mpa, reaction time: 3 hours, carry out reaction and obtain intermediate product aluminum n-hexoxide 640g.

[0040] Aluminum alkoxide compound hydrolysis reaction prepares nanoscale alumina powder Process conditions: the mol ratio of 640g aluminum n-hexoxide and deionized water is 1:3, add 0.5% surfactant polyethylene glycol 600 of aluminum n-hexoxide weight, reaction temperature: 80°C, operating pressure: ≤0.1Mpa, pH value: 7, reaction time: 4 hours, after distillation, separation, and hydrolysis, 156g of hydrated alumina was obtained.

[0041] Roast 100g of hydrated alumina in a muffle furnace at a temperature of 800°C for 2-3 hours, and gradually cool down to room temperature in the furnace to obtain 65g of γ-alumina.

[0042] Roast 56g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com