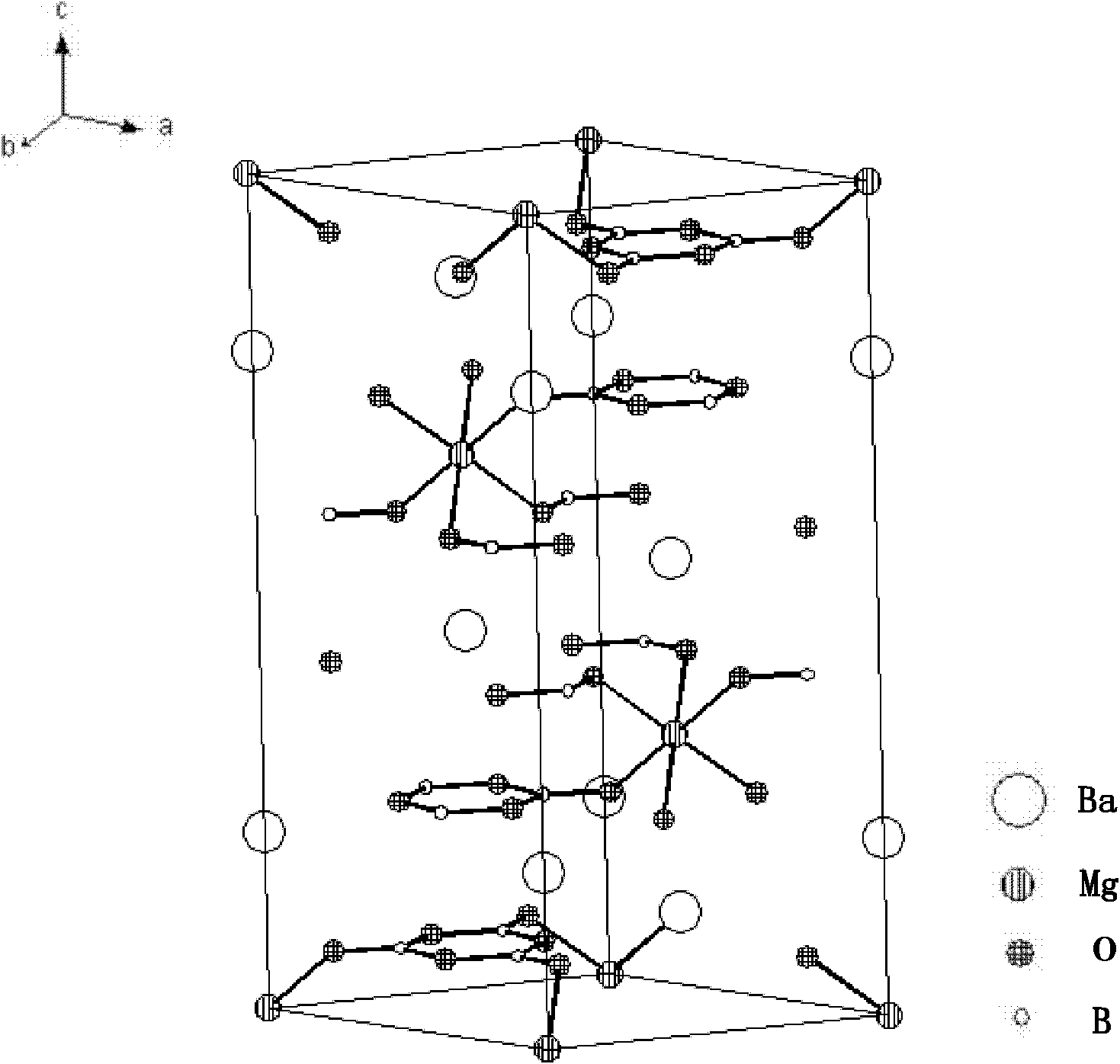

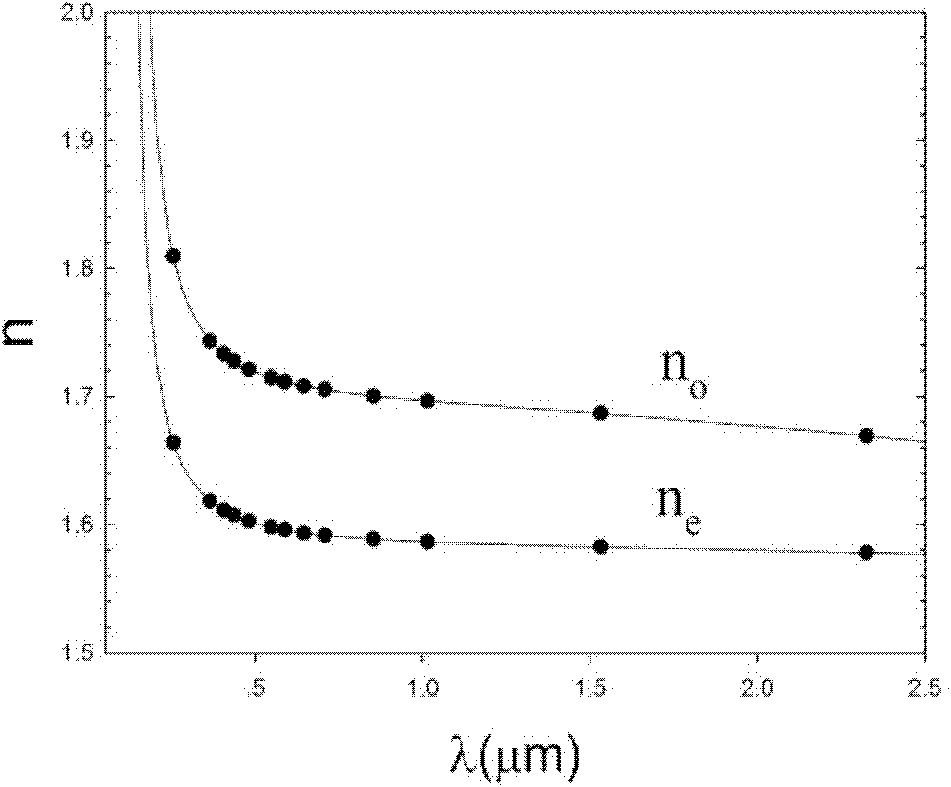

Borate birefringent crystal for ultraviolet and deep ultraviolet, and growth method and application thereof

A technology of birefringent crystals and growth methods, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of easy deliquescence, small birefringence, and low transmission of crystals, and achieve easy polishing, low deliquescence, Easy to save effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the melt pulling method grows Ba 2 Mg(B 3 o 6 ) 2 :

[0031] Raw materials used (analytically pure): BaCO 3 986.7g

[0032] MgO 100.75g

[0033] HBO 3 927.45g

[0034] (the molar ratio of Ba, Mg and B is 2:1:6)

[0035] The specific steps are as follows: after weighing the above raw materials, put them into a mortar for mixing and grinding, then put them into a φ85mm×85mm platinum crucible, heat to a molten state to obtain a mixed melt, stir for 48 hours, and determine the above The saturation point temperature of the mixed melt. Seed crystal when the temperature of the mixed melt is 1°C higher than the saturation point temperature: fix the seed crystal at the end of the seed rod, put the seed rod from the self-made growth furnace, and make it touch the surface of the mixed melt or extend it into the into the melt; 30 minutes after the seed crystal is placed, lower the temperature to the satu...

Embodiment 2

[0036] Embodiment 2, melt spontaneous crystallization method grows Ba 2 Mg(B 3 o 6 ) 2 :

[0037] Raw materials used (analytical pure): BaCO 3 3197.36g

[0038] MgO 20.17g

[0039] HBO 3 185.49g

[0040] (the molar ratio of Ba, Mg and B is 2:1:6)

[0041] The specific steps are as follows: after weighing the above raw materials, put them into a mortar for mixing and grinding, then put them into a φ54mm×48mm platinum crucible, heat to a molten state to obtain a mixed melt, stir for 48 hours, and determine the above Mix the saturation point temperature of the melt, set the temperature at 1 °C above the saturation temperature, put the seed rod without the seed crystal into the melt, and then lower the temperature at a rate of 0.5 °C / hour to make it spontaneously crystallize, and wait for crystallization Finally, the cooling rate is set at 0.5°C / day, and the crystal grows gradually. When the crystal grows to a certain siz...

Embodiment 3

[0042] Embodiment 3, flux method grows Ba 2 Mg(B 3 o 6 ) 2 :

[0043] Raw materials used (analytically pure): BaCO 3 78.95g

[0044] MgO 8.06g

[0045] HBO 3 74.3g

[0046] NaF 1.68g (the molar ratio of Ba, Mg, B and NaF is 2:1:6:0.2, which is equivalent to the molar ratio of BMBO and NaF is 1:0.2)

[0047] The specific steps are as follows: after weighing the above-mentioned raw materials, put them into a mortar, mix and grind them, then put them into a platinum crucible, heat them to a molten state to obtain a mixed melt, stir for 48 hours, and determine the above-mentioned mixed melt by trying the seed crystal. body saturation point. When the temperature of the mixed melt is 3°C higher than the saturation point temperature, plant the seed crystal: fix the seed crystal on the end of the seed crystal rod, put the seed crystal rod from the self-made growth furnace, and make it touch the surface of the mixed melt or extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com