Technology for coating three-layer polyethylene structure on outer wall and fusing epoxy resin on inner wall of steel pipe

A technology of steel pipe inner wall and epoxy resin, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low processing efficiency, inability to resist acid and alkali, and high equipment cost, so as to reduce the power consumption of transmission and ensure the surface Effect of leveling, good corrosion protection properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

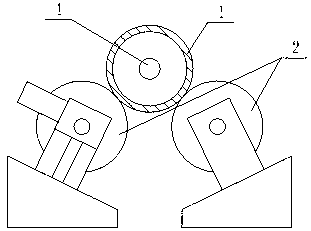

Image

Examples

Embodiment 1

[0025] A process for coating the inner wall of a steel pipe with an epoxy resin outer wall with a three-layer polyethylene structure, comprising the following steps:

[0026] In the first step, after the steel pipe is shot blasted on the inner and outer walls by the shot blasting machine, the inner and outer walls of the steel pipe after the shot blasting treatment are measured by the anchor grain meter to have an anchor grain depth of 50um, and are transported by the conveying device, which drives the steel pipe to wind around itself The axis rotates and advances. The pitch of the steel pipe when it rotates forward is between 80mm. After the steel pipe passes through the intermediate frequency induction furnace and is heated, the temperature of the steel pipe after heating is controlled between 130°C, and the inner wall powder spraying vehicle is started to drive the spraying at the front of the spray gun. The head extends into the front end of the steel pipe, the conveying de...

Embodiment 2

[0031] A process for coating the inner wall of a steel pipe with an epoxy resin outer wall with a three-layer polyethylene structure, comprising the following steps:

[0032] In the first step, after the steel pipe is shot blasted on the inner and outer walls by the shot blasting machine, the inner and outer walls of the steel pipe after the shot blasting treatment are measured by the anchor grain meter as the anchor grain depth of 70um, and are transported by the conveying device, which drives the steel pipe to wind around itself The axis rotates and advances. The pitch of the steel pipe when it rotates forward is between 100mm. After the steel pipe passes through the intermediate frequency induction furnace and is heated, the temperature of the steel pipe after heating is controlled between 160°C, and the inner wall powder spraying vehicle is started to drive the spray at the front of the spray gun. The head extends into the front end of the steel pipe, the conveying device c...

Embodiment 3

[0037] A process for coating the inner wall of a steel pipe with an epoxy resin outer wall with a three-layer polyethylene structure, comprising the following steps:

[0038] In the first step, after the steel pipe is shot blasted on the inner and outer walls by the shot blasting machine, the inner and outer walls of the steel pipe after the shot blasting treatment are measured by the anchor texture meter. The depth of the anchor pattern is 60um. The axis rotates and advances. The pitch of the steel pipe when it rotates forward is between 90mm. After the steel pipe passes through the intermediate frequency induction furnace and is heated, the temperature of the steel pipe after heating is controlled between 150°C, and the inner wall powder spraying vehicle is started to drive the spray at the front end of the spray gun. The head extends into the front end of the steel pipe, the conveying device continues to drive the steel pipe to rotate forward, start the spray gun, and the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com