Disinfection aid for ozone disinfection and method for ozone disinfection

An ozone sterilization and auxiliary technology, applied in the directions of fungicides, biocides, biocides, etc., can solve the problems of rubber, metal, plastic easily corroded, high cost, increased device load, etc., to reduce load, Cost reduction, high sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0167] Escherichia coli (NBRC3972 strain) was cultured on SCD agar medium (manufactured by Nissui Pharmaceutical Co., Ltd.) at 37°C for 24 hours (hereinafter, sometimes referred to as "pre-preculture"), and the cultured Escherichia coli was further mixed with the above-mentioned The previous pre-cultivation was performed again in the same manner (hereinafter, sometimes referred to as "pre-culture"), and the pre-cultured Escherichia coli was used for a bactericidal test.

[0168] The pre-cultured Escherichia coli was dispersed in a buffer solution added with peptone (3.56 g of potassium dihydrogen phosphate, 18.2 g of disodium hydrogen phosphate dodecahydrate, 4.3 g of sodium chloride, and 1.0 g of peptone were dissolved in 1 L of pure water, In the liquid obtained by neutralizing it to pH 7.0), the number of bacteria prepared was 1.0×10 using the transmittance of light with a wavelength of 660 nm as an index. 8 Bacterial solution around cfu / mL.

[0169] Pure water was added t...

Embodiment 13~32

[0189] Escherichia coli (NBRC3972 strain) was cultured on SCD agar medium (manufactured by Nissui Pharmaceutical Co., Ltd.) at 37°C for 24 hours (pre-culture), and the cultured Escherichia coli was further cultured again in the same manner as the previous pre-culture (Pre-culture), the pre-cultured Escherichia coli was used for the bactericidal test. Dilute the pre-cultured Escherichia coli with sterilized water, and use the transmittance of light with a wavelength of 660nm as an index to prepare a bacterial count of 2.0×10 7 Bacterial dilutions of about cfu / mL. Then, the bacterial dilution was dispersed in 5:5 in nutrient broth medium (Nutrientbroth) (manufactured by Kanto Chemical Co., Ltd.) to prepare 1.0×10 7 Bacterial solution around cfu / mL.

[0190] Next, on SUS304 (hairline treatment product) of 2 cm in length and 2 cm in width, silicone rubber (manufactured by Taiga Superima Co., Ltd.), and surface ground glass (polished to No. 1200 water-resistant abrasive paper pro...

Embodiment 33~56

[0240] Using 500g of lettuce as the object to be treated by ozone sterilization, the operations of pre-washing, sterilizing washing, rinsing and dehydration were carried out as shown below with reference to the processing of common fresh food factories. The transfer of the lettuce in each of the above-mentioned operations was carried out in a stainless steel basket (zaru) sterilized with ethanol.

[0241] (pre-washing process)

[0242] The lettuce was prewashed for 2 minutes using a bucket-type washing machine (Denki Baker) (manufactured by Matsushita Electric Industrial Co., Ltd., N-Bk2) that stored 7 L of tap water.

[0243] (Sterilization process)

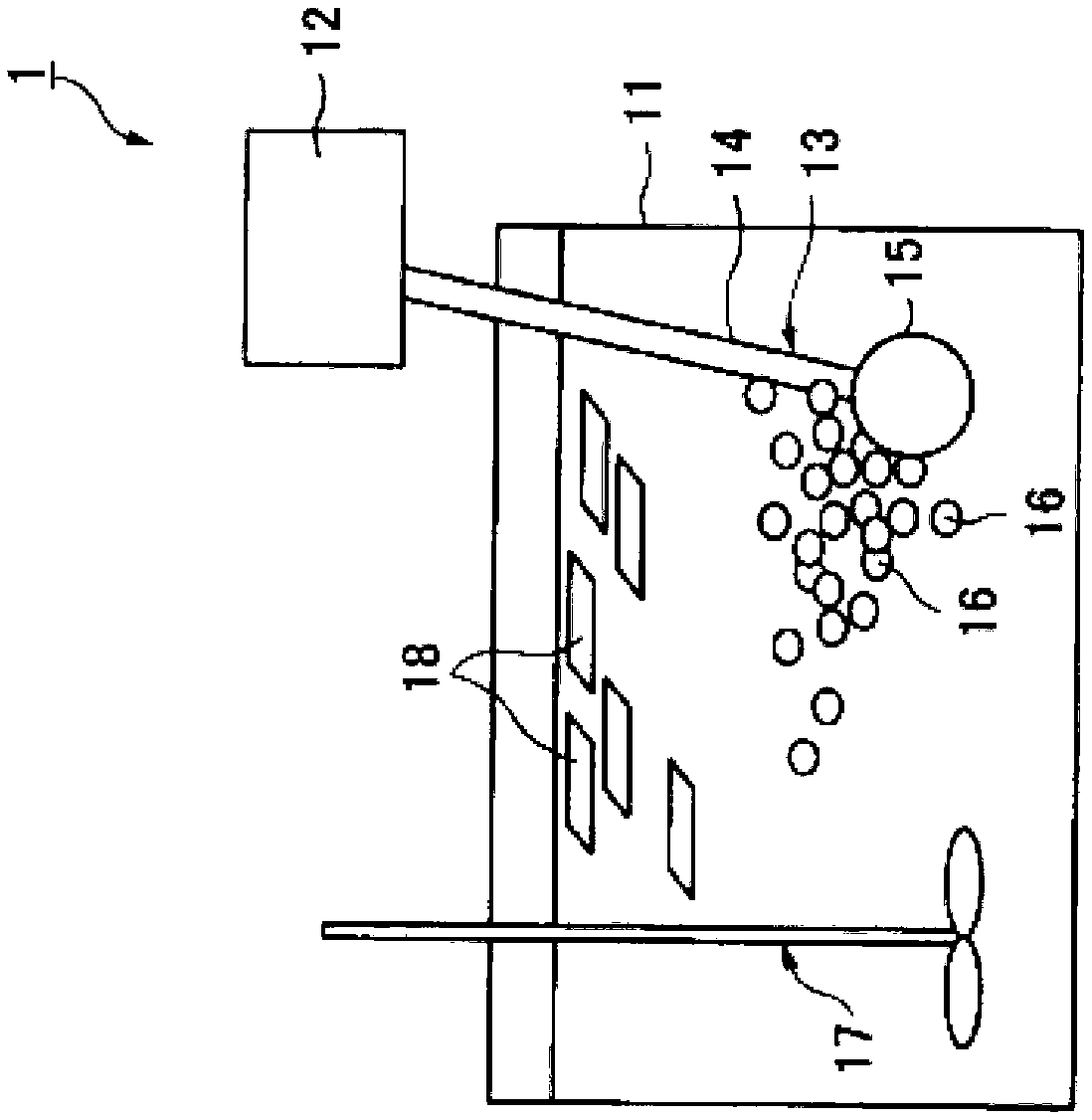

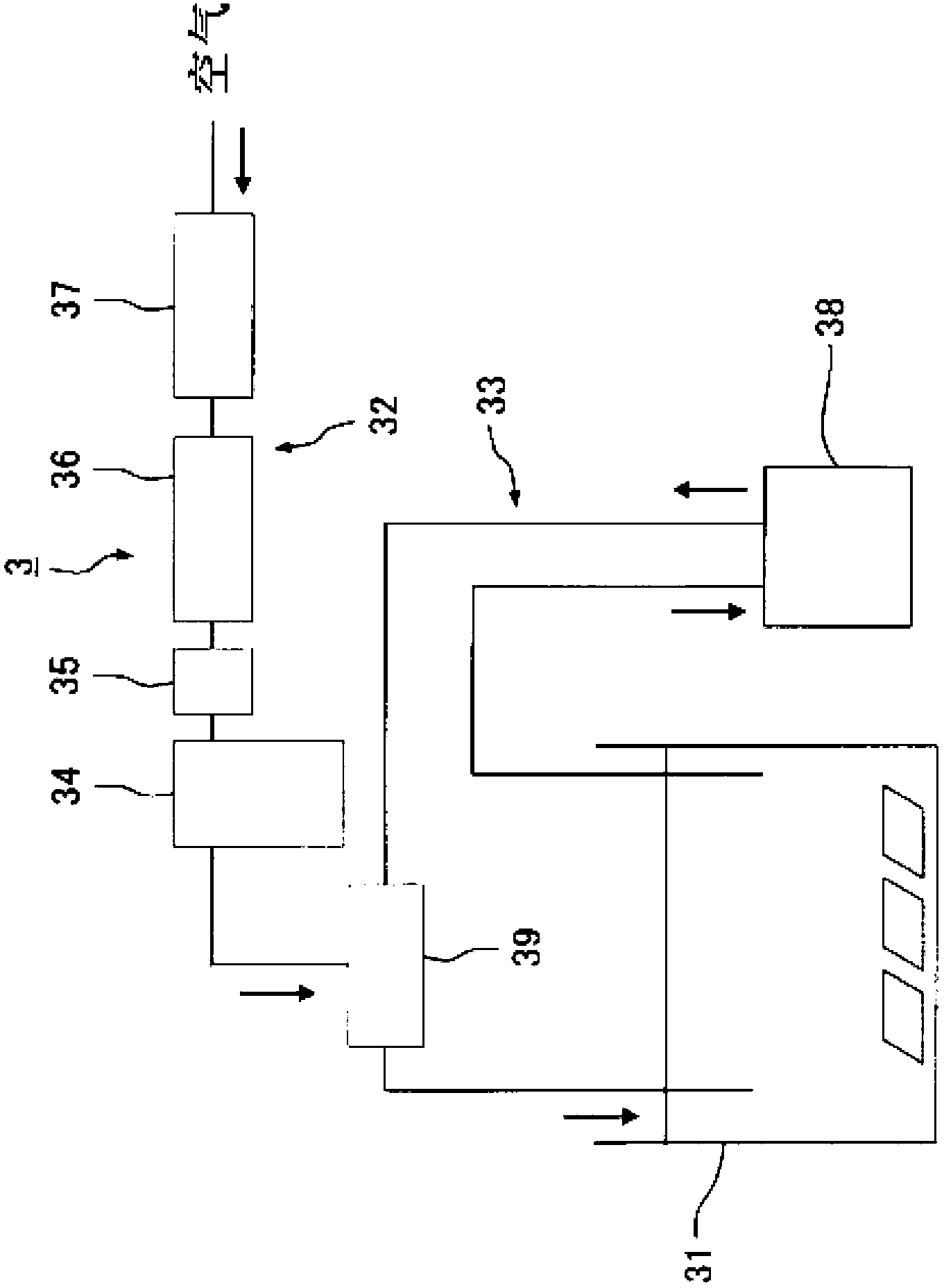

[0244] In the washing tank 41a of the double-tank type washing machine 41 in the described sterilizing device 4, store 40L of bactericidal auxiliary agent, stir, and make miniaturized ozone-containing bubbles produce simultaneously, implement the ozone sterilizing of lettuce for 10 minutes, so The above-mentioned bactericidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com