Low-polylactic acid-beta-cyclodextrin and polylactic acid blended nano-fiber prepared by electrospinning

A technology of nanofibers and cyclodextrins, which can be used in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve the problems of functional loss and achieve good compatibility, good biocompatibility, firm adhesion attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

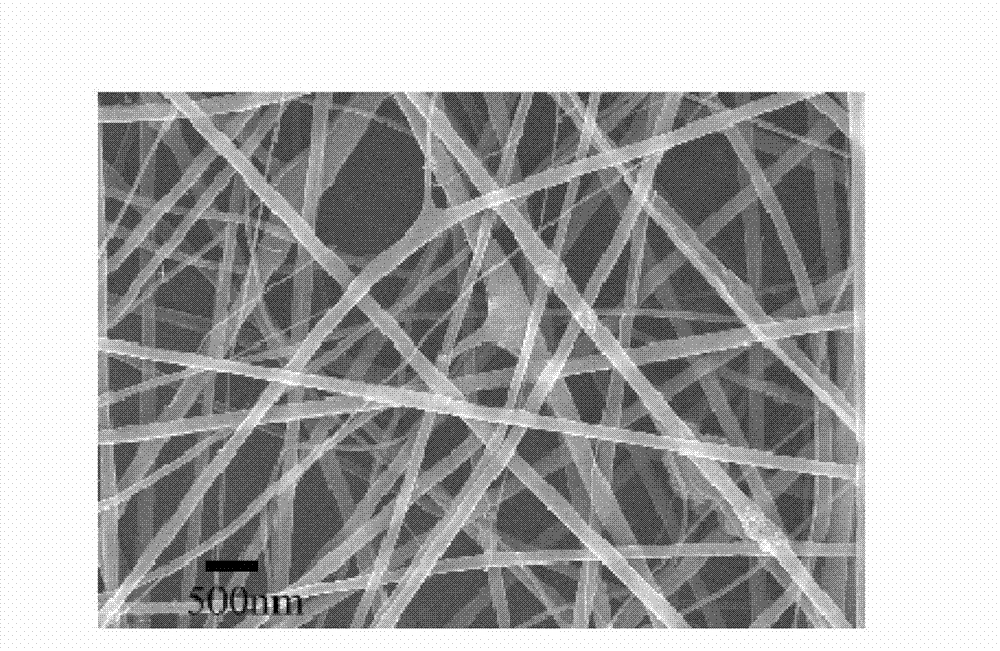

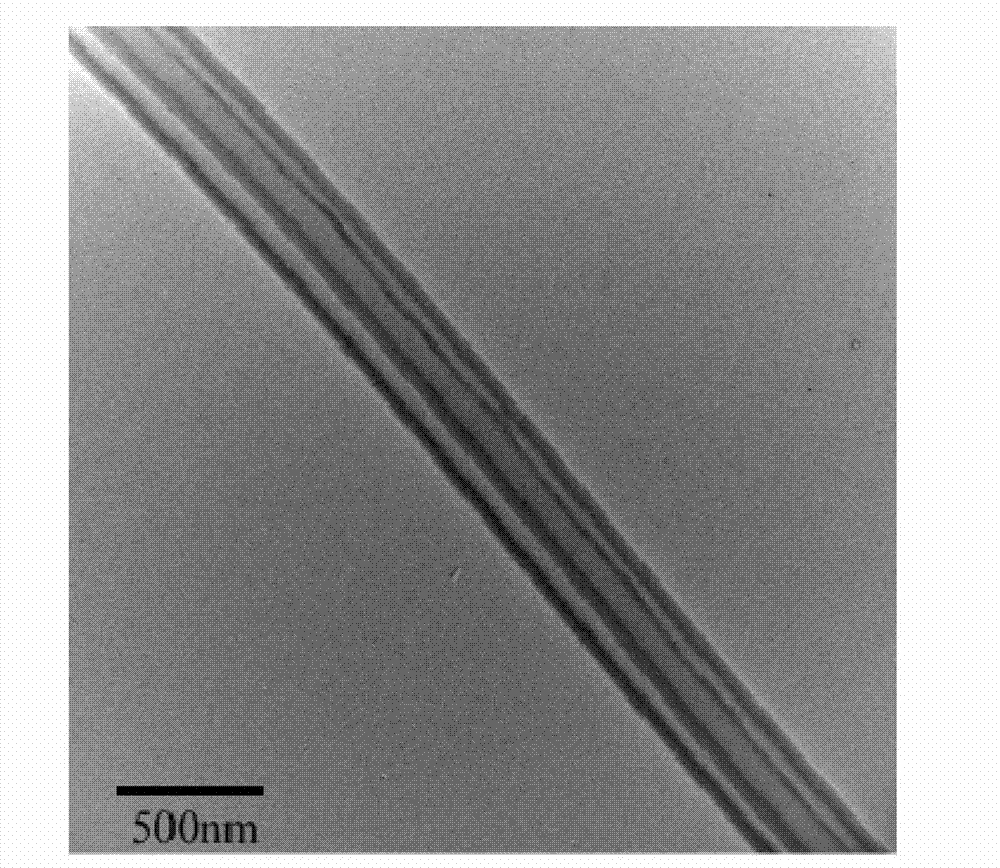

Image

Examples

Embodiment 1

[0018] (1) Dissolve oligomeric lactic acid-β-cyclodextrin with a weight average molecular weight of 3000 and polylactic acid with a weight average molecular weight of 100,000 in dichloromethane with a volume ratio of 1:1 in a mass ratio of 1:10 In a mixed solvent of N,N-dimethylformamide (DMF), prepare a solution with a weight percentage of 20wt%, then stir the solution fully until it is completely dissolved, and place the solution in ultrasonic for 1 hour to make all the bubbles precipitate out That is, a transparent oligomeric lactic acid-β-cyclodextrin / polylactic acid blend solution is obtained.

[0019] (2) Add the oligomeric lactic acid-β-cyclodextrin / polylactic acid blend electrospinning solution prepared in step (1) into the syringe pump, and adjust the spinning voltage to 15kV; the distance from the spinneret to the collecting plate is 15cm; the flow rate of the spinneret spinning solution is 1.5mL / h; the collector is aluminum foil, and the device is started to perform...

Embodiment 2

[0021] (1) Dissolve oligomeric lactic acid-β-cyclodextrin with a weight average molecular weight of 5000 and polylactic acid with a weight average molecular weight of 200,000 in a mass ratio of 5:10 in dichloromethane with a volume ratio of 1:1 In a mixed solvent of N,N-dimethylformamide (DMF), prepare a solution with a weight percentage of 15wt%, then stir the solution fully until it is completely dissolved, and place the solution in ultrasonic for 1 hour to make all the bubbles precipitate out That is, a transparent oligomeric lactic acid-β-cyclodextrin / polylactic acid blend solution is obtained.

[0022] (2) Add the oligomeric lactic acid-β-cyclodextrin / polylactic acid blend electrospinning solution prepared in step (1) into the syringe pump, and adjust the spinning voltage to 15kV; the distance from the spinneret to the collecting plate is 15cm; the flow rate of the spinneret spinning solution is 1.5mL / h; the collector is aluminum foil, and the device is started to perform...

Embodiment 3

[0024] (1) Dissolve oligomeric lactic acid-β-cyclodextrin with a weight average molecular weight of 8000 and polylactic acid with a weight average molecular weight of 300,000 in a mass ratio of 8:10 in dichloromethane with a volume ratio of 1:1 and N,N-dimethylformamide (DMF) in a mixed solvent to prepare a solution with a weight percentage of 10wt%, then stir the solution fully until it is completely dissolved, and place the solution in ultrasonic for 1 hour to make all the bubbles precipitate out That is, a transparent oligomeric lactic acid-β-cyclodextrin / polylactic acid blend solution is obtained.

[0025] (2) Add the oligomeric lactic acid-β-cyclodextrin / polylactic acid blend electrospinning solution prepared in step (1) into the syringe pump, and adjust the spinning voltage to 15kV; the distance from the spinneret to the collecting plate is 15cm; the flow rate of the spinneret spinning solution is 1.5mL / h; the collector is aluminum foil, and the device is started to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com