Soluble self-healing natural polymer hydrogel and preparation method thereof

A natural polymer and hydrogel technology, applied in bandages, surgery, surgical adhesives, etc., can solve problems such as insoluble, slow healing speed, and limited incision healing, and achieve long release time, stable release rate, and healing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

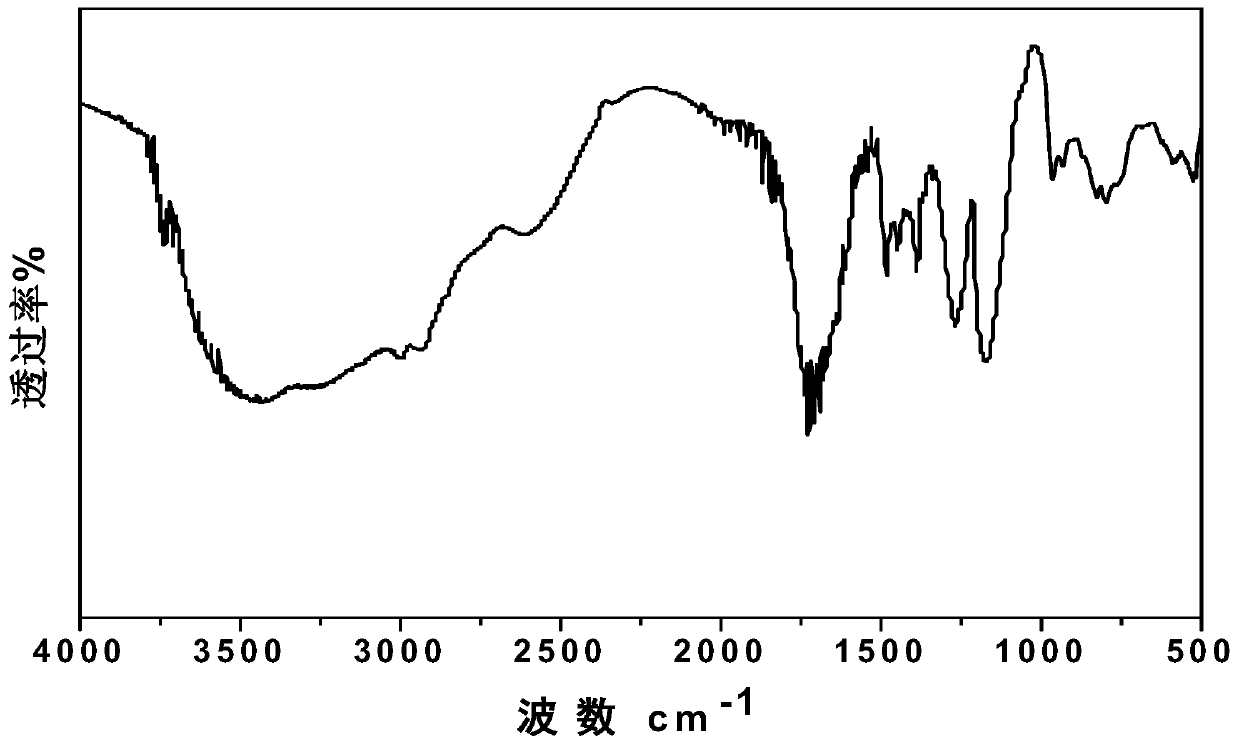

[0039] Synthesis of Soluble Self-Healing Hydrogel (SAM-1)

[0040] Weigh a certain amount of sodium alginate and add it to deionized water (the mass ratio of sodium alginate to deionized water is 4:100), stir at 1500rpm for 3 hours until the sodium alginate is completely dissolved, put the sodium alginate solution in Put it in a refrigerator at 3°C, stabilize it for 3 hours, and wait until it becomes a colorless and transparent sodium alginate aqueous solution.

[0041] Add the prepared sodium alginate aqueous solution into the three-necked flask, stir at 1500rpm for 10 minutes, then slowly add deionized water (the mass ratio of sodium alginate solution to deionized water is 4:1), maintain the stirring speed, and continue stirring For 30 minutes, the temperature was kept at 25°C.

[0042] To the mixed sodium alginate solution, slowly add methacrylic acid (the mass ratio of sodium alginate mixed solution to methacrylic acid is 8:1), and the dropwise addition is completed withi...

Embodiment 2

[0045] Synthesis of Soluble Self-Healing Hydrogels (SAM-2)

[0046] Weigh a certain amount of sodium alginate and add it to deionized water (the mass ratio of sodium alginate to deionized water is 2:100), stir at 1200rpm for 5 hours until the sodium alginate is completely dissolved, put the sodium alginate solution in Put it in a refrigerator at 8°C, stabilize it for 6 hours, and wait until it becomes a colorless and transparent sodium alginate aqueous solution.

[0047] Add the prepared sodium alginate aqueous solution into a three-necked flask, stir at 1200rpm for 10 minutes, then slowly add deionized water (the mass ratio of sodium alginate solution to deionized water is 4:2), maintain the stirring speed, and continue stirring 50min, the temperature was kept at 25°C.

[0048] To the mixed sodium alginate solution, slowly add methacrylic acid (the mass ratio of sodium alginate mixed solution to methacrylic acid is 4:1), the dropwise addition is completed within 2 hours, kee...

Embodiment 3

[0051] Synthesis of Soluble Self-Healing Hydrogel (SAM-3)

[0052] Weigh a certain amount of sodium alginate and add it to deionized water (the mass ratio of sodium alginate to deionized water is 1:100), stir at 800rpm for 6 hours until the sodium alginate is completely dissolved, put the sodium alginate solution in Put it in a refrigerator at 10°C, stabilize it for 10 hours, and wait until it becomes a colorless and transparent sodium alginate aqueous solution.

[0053] Add the prepared sodium alginate aqueous solution into the three-necked flask, stir at 800rpm for 10 minutes, then slowly add deionized water (the mass ratio of sodium alginate solution to deionized water is 4:3), maintain the stirring speed, and continue stirring For 60 minutes, the temperature was kept at 25°C.

[0054] To the mixed sodium alginate solution, slowly add methacrylic acid (the mass ratio of sodium alginate mixed solution to methacrylic acid is 2:1), and the dropwise addition is completed withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com