Layer-number-controllable graphite film based on nickel-copper composite substrate and preparation method of film

A technology of graphene film and composite substrate, which is applied in the direction of graphene, coating, metal material coating process, etc., can solve the problems of graphene film size limitation, complicated process, high hardware investment and high preparation cost, and achieve shape and The effect of less size limitation, strong layer number control ability and wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

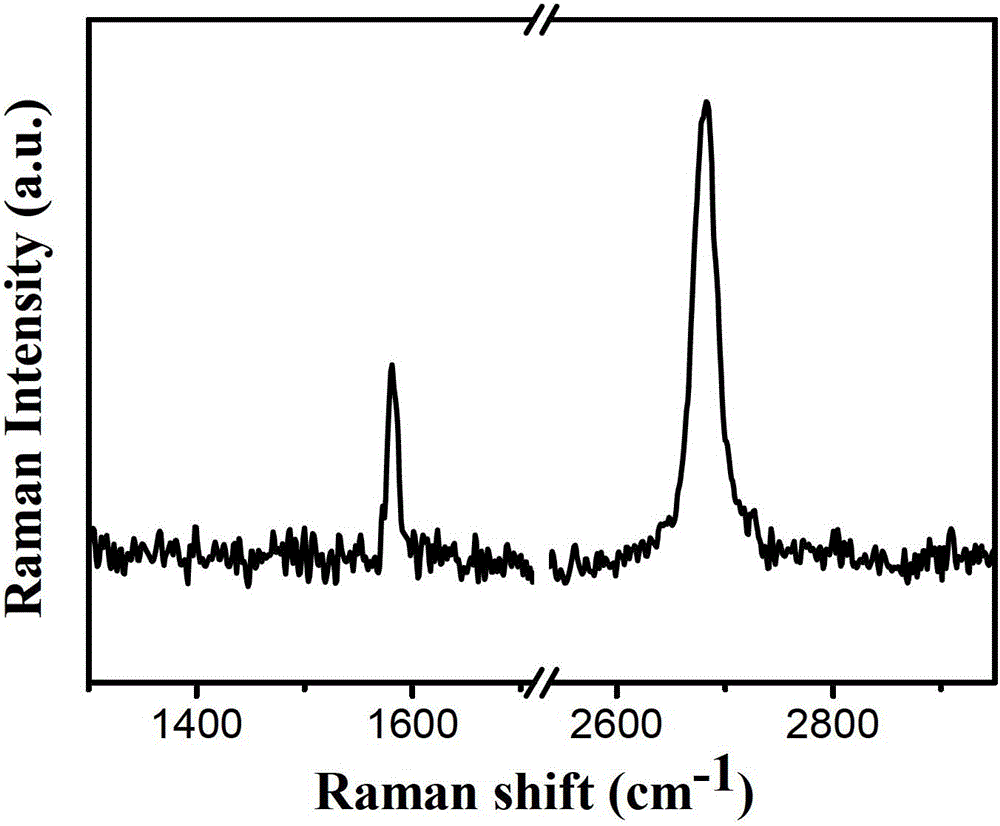

[0039]The preparation of embodiment 1 monolayer graphene

[0040] 1. Experimental method

[0041] 1) Ni-Cu composite substrate: cut copper foil with a thickness of 25 μm, a purity of 99.8%, a width of 10 cm, and a length of 50 cm. Copper foils were cleaned with acetone and isopropanol and dried with nitrogen. A 150nm metal Ni layer was formed on the surface of Cu using industrial nickel plating process (for nickel plating method refer to electrodeposition nanocrystalline material technology, edited by Tu Zhenmi et al., National Defense Industry Press, publication date: April 1, 2008, ISBN: 9787118055528).

[0042] 2) Carburizing process: use liquid benzene as carbon source, heat to 150-200°C, base temperature is 300°C, keep for 30 minutes, Ar flow rate is 300sccm, H 2 The flow rate is 2 sccm.

[0043] 3) Carbon precipitation process: Cut off the carbon source, raise the substrate temperature to 500°C, keep it warm for 60 minutes, Ar flow rate is 300 sccm, H 2 The flow rate...

Embodiment 2

[0046] The preparation of embodiment 2 monolayer graphene

[0047] The carbon source is replaced by solid carbon sources such as phenanthrene, pyrene, polystyrene, polymethyl methacrylate to prepare the graphene film of the nickel-copper composite substrate, and other parameters are the same as embodiment 1, and the method is as follows:

[0048] method one:

[0049] 1) Ni-Cu composite substrate: cut copper foil with a thickness of 25 μm, a purity of 99.8%, a width of 10 cm, and a length of 50 cm. Copper foils were cleaned with acetone and isopropanol and dried with nitrogen. A 150nm nickel layer is formed on the surface of the copper foil using an industrial nickel plating process.

[0050] 2) Carburizing process: use phenanthrene as carbon source, weigh 0.015g phenanthrene, heat to 100-150°C, base temperature is 300°C, hold for 60 minutes, Ar flow rate is 300sccm.

[0051] 3) Carbon precipitation process: cut off the carbon source, raise the substrate temperature to 600°C...

Embodiment 3

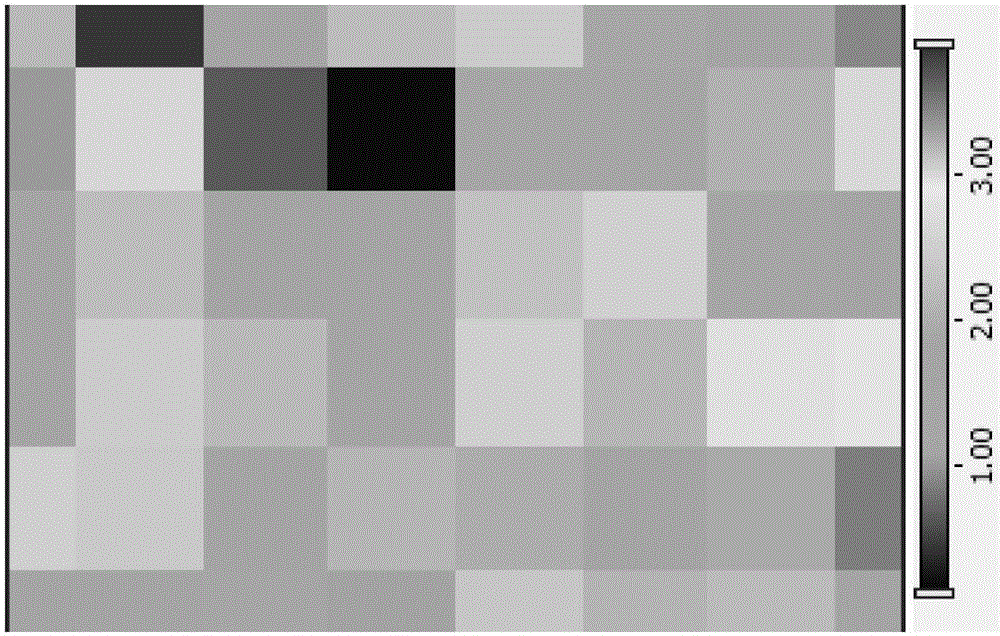

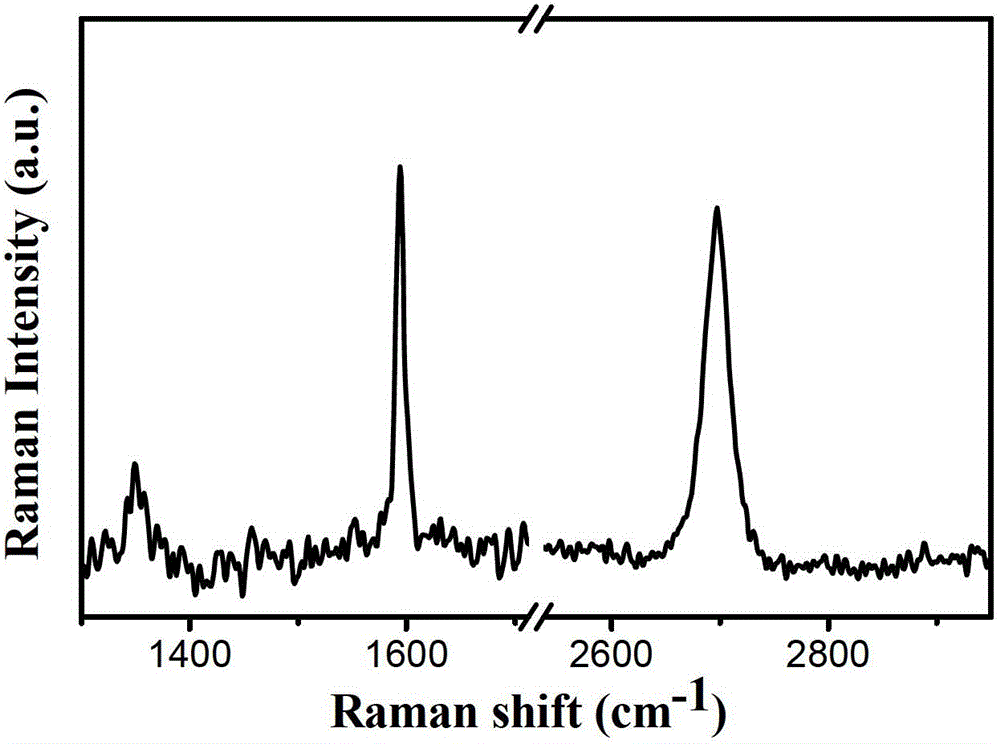

[0068] The preparation of embodiment 3 multilayer graphene

[0069] 1. Experimental method

[0070] 1) Ni-Cu composite substrate: cut copper foil with a thickness of 25 μm, a purity of 99.9%, a width of 20 cm, and a length of 20 cm. The cut copper foils were cleaned with acetone and isopropanol and then dried with nitrogen. A 600nm nickel layer is formed on the copper foil surface using an industrial nickel plating process.

[0071] 2) Carburizing process: take Nai as carbon source, heat to 80-120°C, base temperature is 300°C, keep for 60 minutes, Ar flow rate is 300sccm, H 2 The flow rate is 2 sccm.

[0072] 3) Carbon precipitation process: the substrate temperature is raised to 650°C, kept for 20-180 minutes, the Ar flow rate is 300 sccm, the H 2 The flow rate is 1 sccm.

[0073] 2. Experimental results: Raman results show that there is carbon signal after 20 minutes of heat preservation, but there is no graphene, and double-layer graphene is formed after 40 minutes of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com