Warm mixing additive of asphalt mixture, preparation method and application method thereof

A technology of asphalt mixture and application method, applied in the directions of climate change adaptation, building insulation materials, building components, etc., can solve the problems of small reduction of mixing temperature, prolonged construction time, insignificant warm mixing effect, etc., to improve adhesion performance, prolonging service life, and preventing early pit disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

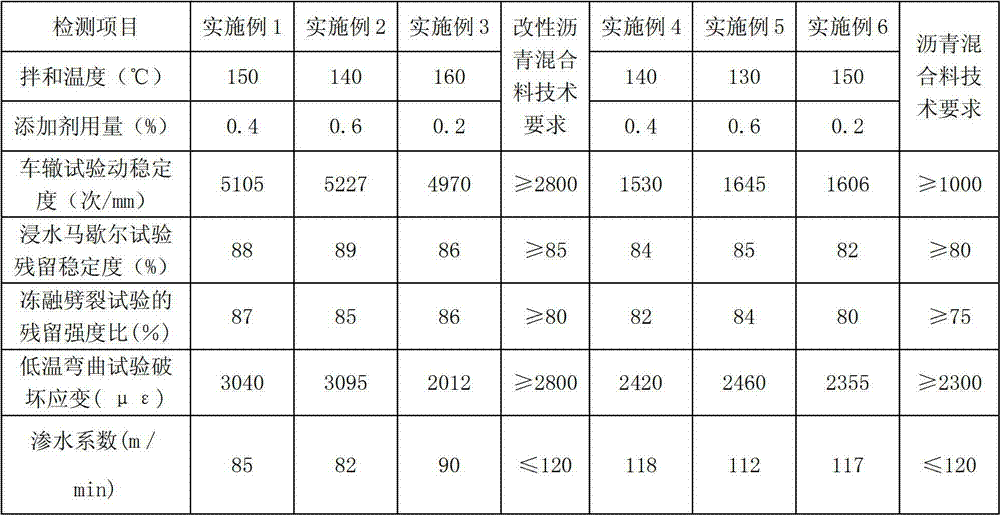

Examples

Embodiment 1

[0029] Take the preparation of 100kg warm mix additive for asphalt mixture as an example to illustrate.

[0030] Weigh 60 kg of 100 mesh natural zeolite powder, 25 kg of emulsion, and 15 kg of nano silicon dioxide.

[0031] The composition of the emulsion is: SK-90 petroleum asphalt 5kg, cetyltrimethylammonium bromide 0.75kg, styrene-butadiene latex (SBR) 0.75kg, water 18.5kg.

[0032] The preparation method of the emulsion: first add cetyl trimethyl ammonium bromide to 60 ℃ water and stir to form an emulsifier aqueous solution; then cetyl trimethyl ammonium bromide aqueous solution, styrene-butadiene latex (SBR), Put SK-90 petroleum asphalt at 130°C into an emulsifier, emulsify and shear to obtain an emulsion.

[0033] Preparation method of asphalt mixture warm mix additive:

[0034] Get 60kg of natural zeolite powder and join in the mixer, then take 25kg of emulsion and join in the mixer, after stirring evenly, add 15kg of nano silicon dioxide, after mixing, join the compo...

Embodiment 2

[0038] Take the preparation of 100kg warm mix additive for asphalt mixture as an example to illustrate.

[0039] Weigh 50 kg of 180-mesh synthetic zeolite powder, 20 kg of emulsion, and 30 kg of nano-titanium dioxide.

[0040] The composition of the emulsion is: 0.2 kg of tallow propylene diamine, 0.2 kg of natural rubber latex (NR), and 19.6 kg of water.

[0041] The preparation method of the emulsion: first add tallow-based propylene diamine to 50°C water and stir to form an aqueous emulsifier solution; then add tallow-based propylene diamine aqueous solution and natural rubber latex (NR) into the emulsifier, emulsify, shear, Get lotion.

[0042] Preparation method of asphalt mixture warm mix additive:

[0043] Take 50kg of synthetic zeolite powder and add it to the mixer, then take 20kg of emulsion and add it to the mixer, after stirring evenly, add 30kg of nano-titanium dioxide, after mixing, add the composition to the disc granulator to prepare granular Warm mix additi...

Embodiment 3

[0047] Take the preparation of 100kg warm mix additive for asphalt mixture as an example to illustrate.

[0048] Weigh 70kg of 60 mesh natural zeolite powder, 28kg of emulsion, and 2kg of nano-zinc oxide.

[0049] The composition of the emulsion is: SK-90 petroleum asphalt 8.4kg, alkylphenol polyoxyethylene ether OP-10 1.4kg, neoprene latex (CR) 1.4kg, water 16.8kg.

[0050] The preparation method of the emulsion: first add the alkylphenol polyoxyethylene ether OP-10 to 70°C water and stir to form an emulsifier aqueous solution; then add the alkylphenol polyoxyethylene ether OP-10 aqueous solution, chloroprene latex (CR), Put SK-90 petroleum asphalt at 140°C into an emulsifier, emulsify and shear to obtain an emulsion.

[0051] Preparation method of asphalt mixture warm mix additive:

[0052] Take 70kg of natural zeolite powder and add it to the mixer, and then take 28kg of emulsion and add it to the mixer. After stirring evenly, add 2kg of nano-zinc oxide, and after mixing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com