High-tensile-strength impact modifier for PVC (polyvinyl chloride) and preparation technique thereof

An impact modifier and high tensile strength technology, which is applied in the field of PVC impact modifier preparation, can solve the problems of poor weather resistance, low tensile strength, and limit the application and promotion of CPE, so as to improve weather resistance and processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

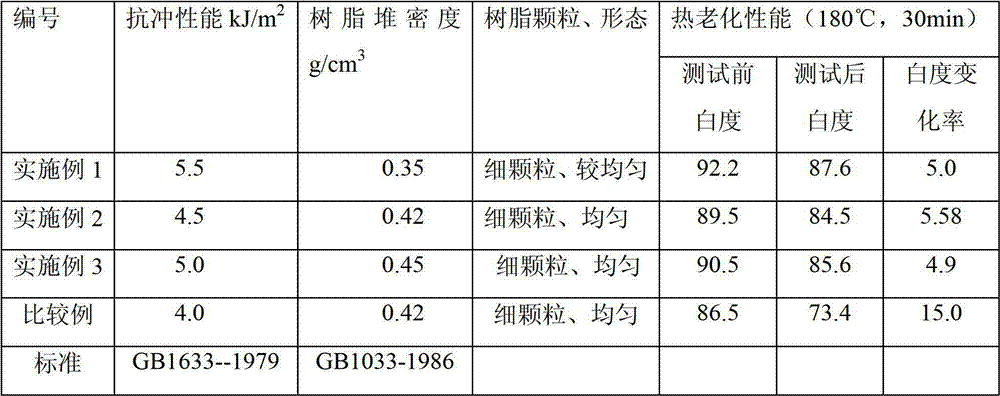

Examples

Embodiment 1

[0025] The high tensile strength impact modifier for PVC, the following parts by weight are based on 100 parts by weight of polyethylene, and its preparation process is as follows:

[0026] (1) Mix 2.0 parts by weight of glycidyl methacrylate, 0.5 parts by weight of styrene, 1.5 parts by weight of tert-butyl peroxybenzoate, and 0.3 parts by weight of dodecyl mercaptan to form a modified mixed system;

[0027] (2) Add the mixing system in step (1) and 100 parts by weight of HDPE into a high-speed mixer, set the speed at 3000r / min for mixing, wait until the temperature of the material rises to 85-90°C, discharge, dry and pulverize to 70-90 mesh, obtain glycidyl methacrylate modified polyethylene copolymer;

[0028] (3) Add 1000 parts by weight of 20wt.% hydrochloric acid solution, 100 parts by weight of glycidyl methacrylate modified polyethylene copolymer obtained in step (2), 1.5 parts by weight of polyvinyl alcohol, carbonic acid Calcium 5.0 parts by weight, then stir and di...

Embodiment 2

[0031] The high tensile strength impact modifier for PVC, the following parts by weight are based on 100 parts by weight of polyethylene, and its preparation process is as follows:

[0032] (1) Mix 1.0 parts by weight of glycidyl methacrylate, 1.0 parts by weight of methyl methacrylate, 1.0 parts by weight of dicumyl peroxide, and 0.2 parts by weight of dodecyl mercaptan to form a modified mixed system;

[0033] (2) Add the mixing system in step (1) and 100 parts by weight of HDPE into a high-speed mixer, set the speed at 3000r / min for mixing, wait until the temperature of the material rises to 85-90°C, discharge, dry and pulverize to 70-90 mesh, obtain glycidyl methacrylate modified polyethylene copolymer;

[0034] (3) Add 1000 parts by weight of 20wt.% hydrochloric acid solution, 100 parts by weight of glycidyl methacrylate modified polyethylene copolymer obtained in step (2), 1.4 parts by weight of hydroxypropyl methylcellulose to the chlorination kettle in sequence Parts ...

Embodiment 3

[0037] The high tensile strength impact modifier for PVC, the following parts by weight are based on 100 parts by weight of polyethylene, and its preparation process is as follows:

[0038](1) Mix 0.8 parts by weight of glycidyl methacrylate, 0.8 parts by weight of maleic anhydride, 0.5 parts by weight of dibenzoyl peroxide, and 0.08 parts by weight of dodecyl mercaptan to form a modified mixed system;

[0039] (2) Add the mixing system in step (1) and 100 parts by weight of HDPE into a high-speed mixer, set the speed at 3000r / min for mixing, wait until the temperature of the material rises to 85-90°C, discharge, dry and pulverize to 70-90 mesh, obtain glycidyl methacrylate modified polyethylene copolymer;

[0040] (3) Add 1000 parts by weight of 20wt.% hydrochloric acid solution, 100 parts by weight of glycidyl methacrylate modified polyethylene copolymer obtained in step (2), and 1.6 parts by weight of alkylphenol polyoxyethylene ether to the chlorination kettle. parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com