Method for industrially producing industrial, cell-grade or high-purity lithium hydroxide monohydrate

A technology of monohydrate lithium hydroxide and lithium hydroxide, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problem of low industrial production of lithium hydroxide, low lithium hydroxide yield, and inability to meet market demand, etc. problems, to achieve good industrial application prospects, reduce production costs, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

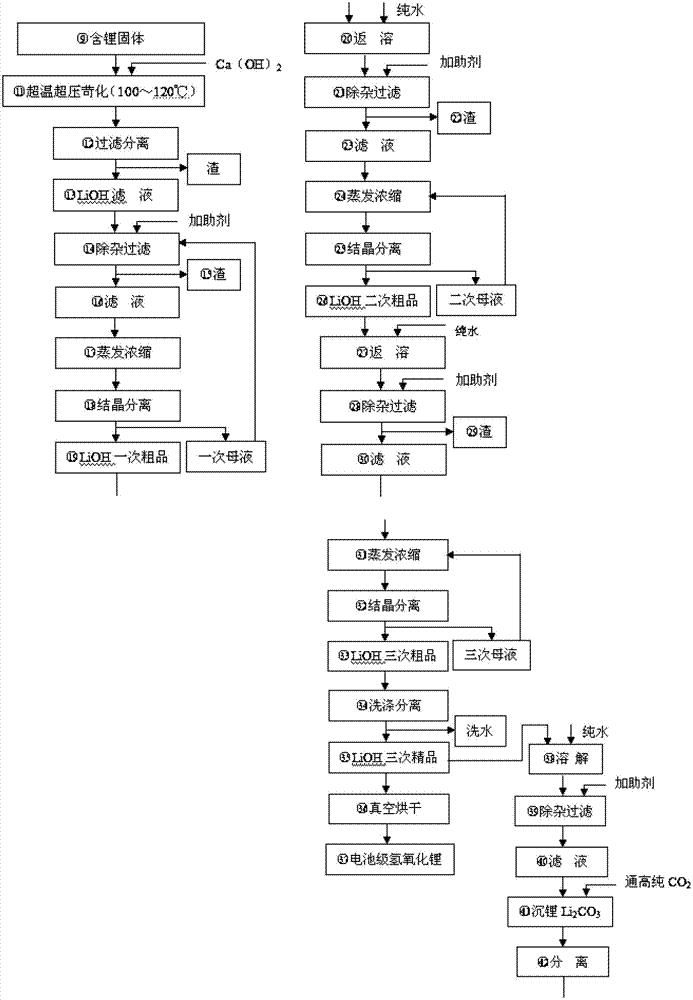

[0058] Embodiment 1 The present invention prepares the method for battery-grade lithium hydroxide

[0059] according to figure 1 Shown technological process, prepares high-purity lithium carbonate:

[0060] (1), Grinding

[0061] ① Take the salt lake type lithium mine, which is the Zabuye salt lake lithium mine (Li 2 O: 5.0~40.3%)

[0062] ②coarse crushing: crush the material directly, the particle size is less than 50mm

[0063] ③Drying The drying temperature is controlled within 350°C, and the moisture content of the material is less than 3%.

[0064] ④Fine Grinding Use ultra-fine powder grinding material particle size <50μm

[0065] (2) Impurity removal by thermal precipitation

[0066] ⑤Separation of lithium and sodium once. Heat the material ④ or the sodium-containing liquid ⑩ in a reaction kettle with a solid-to-liquid mass volume ratio of 1:2 to 90°C for hot agitation. After keeping the temperature for 20-30 minutes, separate and dry it with a centrifuge to obtain...

Embodiment 2

[0114] The preparation of embodiment 2 high-purity lithium carbonate

[0115] LiOH prepared in Example 1 was dissolved in pure water for three wet fine works, and the solution Li 2 O: 60~90g / L

[0116] Add EDTA to further remove Ca 2+ , Fe 3+ , Mg 2+ 、Si 4+ , B 3+ and other impurities, and filter

[0117] The filtrate was clear and transparent, Li 2 O: 60~90g / L

[0118] Introduce high-purity CO 2 In the sealed carbonization tower, CO control 2 flow rate

[0119] Control the pressure at 0.01~0.1MPa

[0120] Centrifugal separation High purity Li 2 CO 3 Moisture content of wet crude product <8%

[0121] Will Li 2 CO 3 Add pure water to the wet crude product, stir and wash at a constant temperature of 90-120°C for 10-30 minutes at a solid-to-liquid ratio of 1:2-5

[0122] centrifugal separation

[0123] Moisture content of high-purity lithium carbonate wet product <8%

[0124] Dry at 200-500°C, moisture <0.05%

[0125] High-purity lithium ca...

Embodiment 3

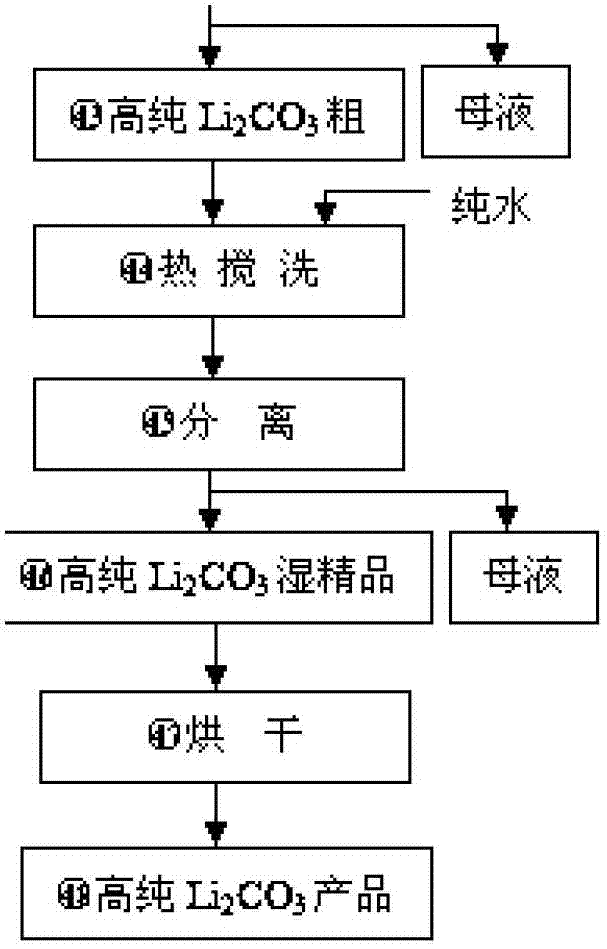

[0126] Embodiment 3 The present invention prepares the method for industrial grade lithium hydroxide

[0127] according to figure 2 Shown technological process, prepares high-purity lithium carbonate:

[0128] (1), Grinding

[0129] ① Take carbonate type lithium concentrate (Li 2 O: 5.0~40.3%, such as Zabuye Salt Lake lithium mine);

[0130] ②Coarse crushing: crush the lithium concentrate to a particle size of ≤5mm;

[0131] ③Drying: Drying temperature ≤ 350 ℃, drying to material moisture ≤ 3%;

[0132] ④ Fine grinding: use ultra-fine powder to grind until the particle size of the material is ≤ 80 μm.

[0133] (2) Impurity removal by thermal precipitation

[0134] ⑤Lithium-sodium separation, the material ④ or the sodium-containing liquid ⑩ is separated and dried by solid-liquid mass, and the lithium-containing solid and the sodium-containing liquid are obtained; the volume ratio is 1:2, heated to 90°C in the reaction kettle, and the temperature is 20~ centrifuge after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com