Welding method for prolonging service life of high-strength metal shell

A metal shell and welding method technology, applied in welding equipment, metal processing equipment, arc welding equipment, etc., can solve the problems of poor welding process parameters, high welding current, low strength, etc., and reduce the occurrence of crack defects Probability, reduction of delayed cracks, convenient and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution is described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

[0030] A welding method for prolonging the service life of a high-strength metal shell. The high-strength metal shell is welded into a metal shell by using high-strength wear-resistant steel CrNiMo as a welding base material. The welding construction process is as follows:

[0031] Preparation before welding→spot welding→preheating→welding→polishing→hydrogen elimination treatment and heat treatment→non-destructive testing. Selection of welding process parameters:

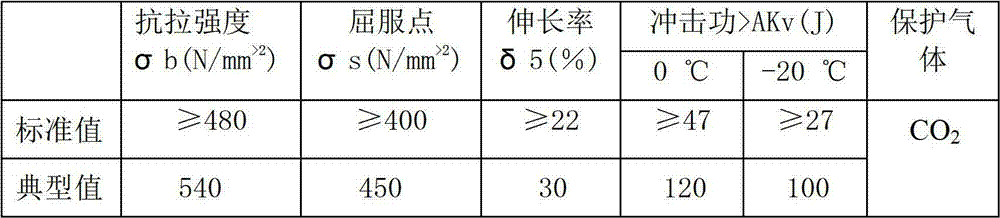

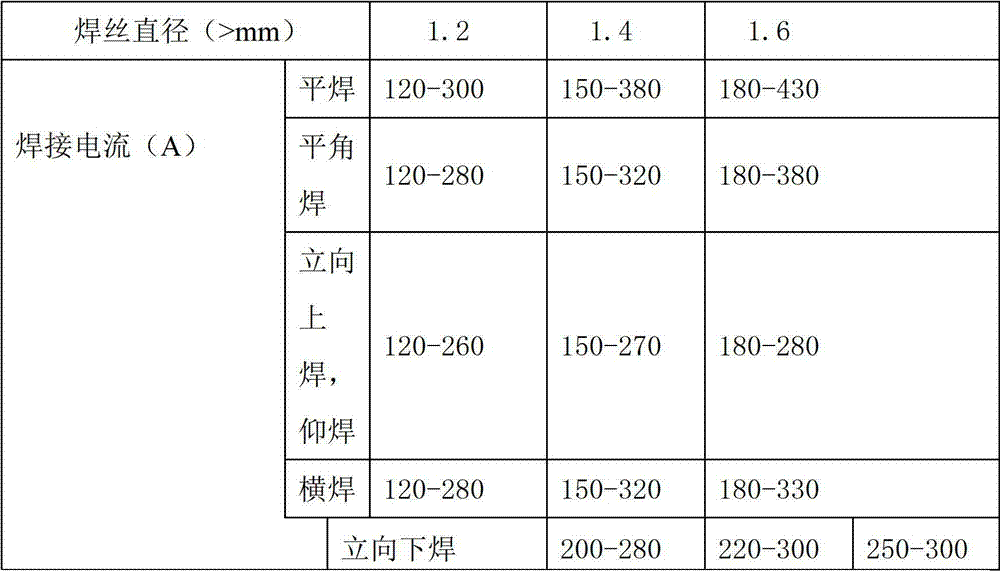

[0032] 1. Welding consumables: The present invention considers that the high-strength CrNiMo steel has a greater tendency to cold cracks. In order to obtain more toughness reserves to obtain better impact resistance and crack resistance, we choose welding wire CHT711 flux-cored welding wire, which is deposited High efficiency, good all-position welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com