MAG/MIG automatic welding device and method

An automatic welding and gas shielding technology, applied in welding equipment, welding connection methods, arc welding equipment, etc., can solve the problems of reducing welding residual stress and residual deformation, low welding productivity, and saving welding wire and electric energy. Reduced consumption of shielding gas, reduced welding production costs, and high mechanical properties of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

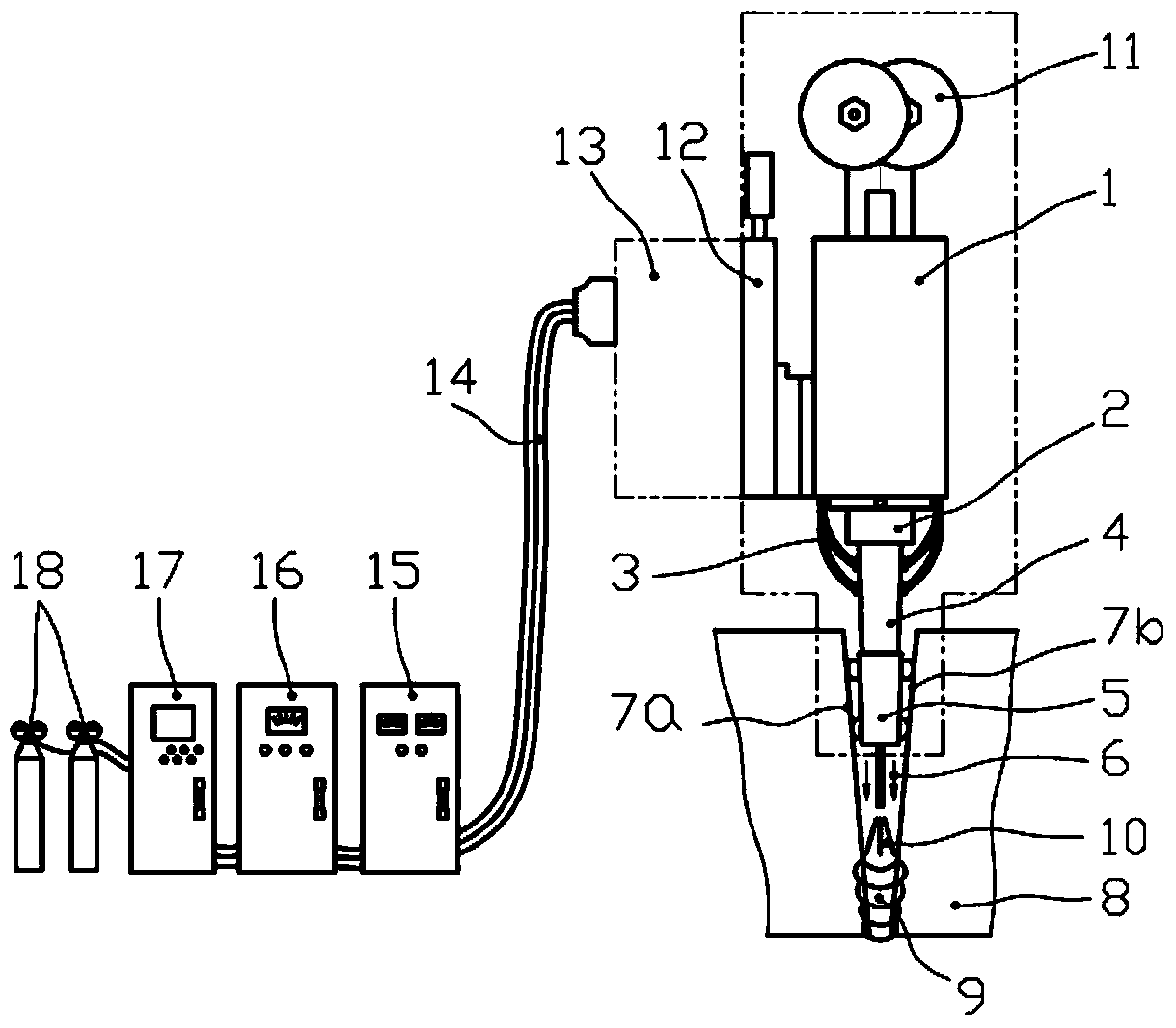

[0052] Example 1: is a basic embodiment of the present invention. Such as figure 1 , 4 , shown in 5, a kind of narrow gap / ultra-narrow gap gas-shielded automatic welding equipment includes a wire feeding mechanism 1, a wire reel 11 is installed on its top, and a three-dimensional self-adaptive centering device 2 is installed on the bottom; the three-dimensional self-adaptive centering The lower part of the device 2 is insulated and fixed an integral plate welding torch 4 whose outer layer has an insulating layer and the center line of the wire feeding channel coincides with the axis of the welding wire 6; There is a gas distribution device 20; the lower part of the gas distribution device 20 is connected to the protective nozzle 21; there are also water / gas pipelines 3, welding torch height adjustment mechanism 12, automatic welding operation mechanism 13, arc welding power supply 15 and cooling cabinet 16, and control Cabinet 17, control cables / welding cables 14 and shiel...

Embodiment 2

[0054] Example 2: is a further example. Such as figure 1 As shown, the narrow-gap / ultra-narrow-gap gas shielded automatic welding equipment has a welding torch height adjustment mechanism 12 connected to the wire feeding mechanism 1 for adjusting the wire feeding mechanism 1, the plate welding torch 4, and the three-dimensional self-adaptive centering device 2 and the exact height of the wire reel 11 along the thickness direction of the weldment 8; the ball screw can be driven by an AC servo motor, and the plate gun 4 is fixed on the screw nut; any other mechanism that can realize the above-mentioned transmission function can also be used; The height adjustment stroke of the plate welding torch 4 matches the maximum weldable plate thickness of the equipment model, and the stroke should generally be about 50mm greater than the maximum weldable piece 8 plate thickness.

[0055] Such as figure 1 As shown, the automatic welding manipulator 13 can be of different structural typ...

Embodiment 3

[0061] Example 3 : be the basic embodiment of the welding method with the narrow gap / ultra-narrow gap gas shielded automatic welding equipment of the present invention, comprising the following steps:

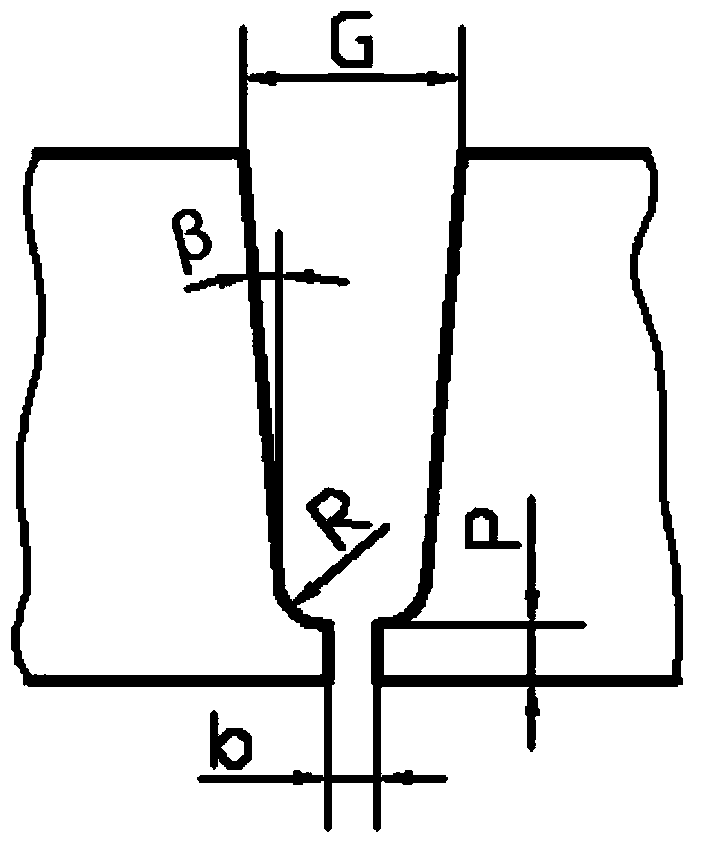

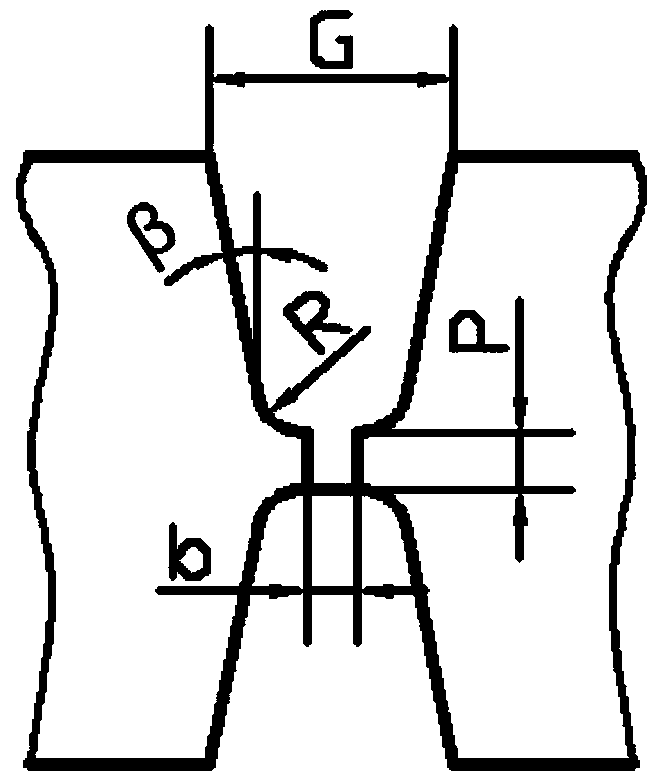

[0062] A. Determine the type and size of the welding groove;

[0063] B. Determine the side slip angle of the welding wire;

[0064] C. Determine the deposition method;

[0065] D. Determine the root assembly gap;

[0066] E. Determine the welding heat input and welding parameters of each layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com