Short-flow method for preparing antimony or bismuth hydrolysis mother solution and composite cleaning agent for short-flow method

A purifying agent and mother liquor technology, applied in the field of metallurgy and chemical industry, can solve the problems of weak reducibility of sodium thiosulfate, slow arsenic reduction process, long arsenic removal process cycle, etc., and achieves improved raw material adaptability, easy process control, and raw material adaptability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

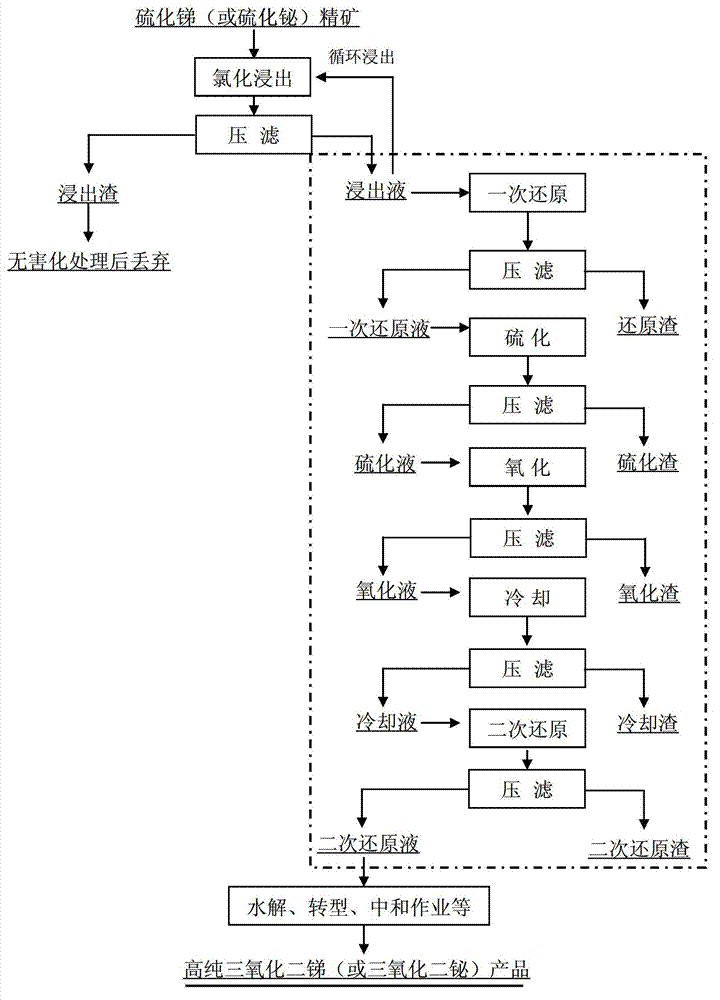

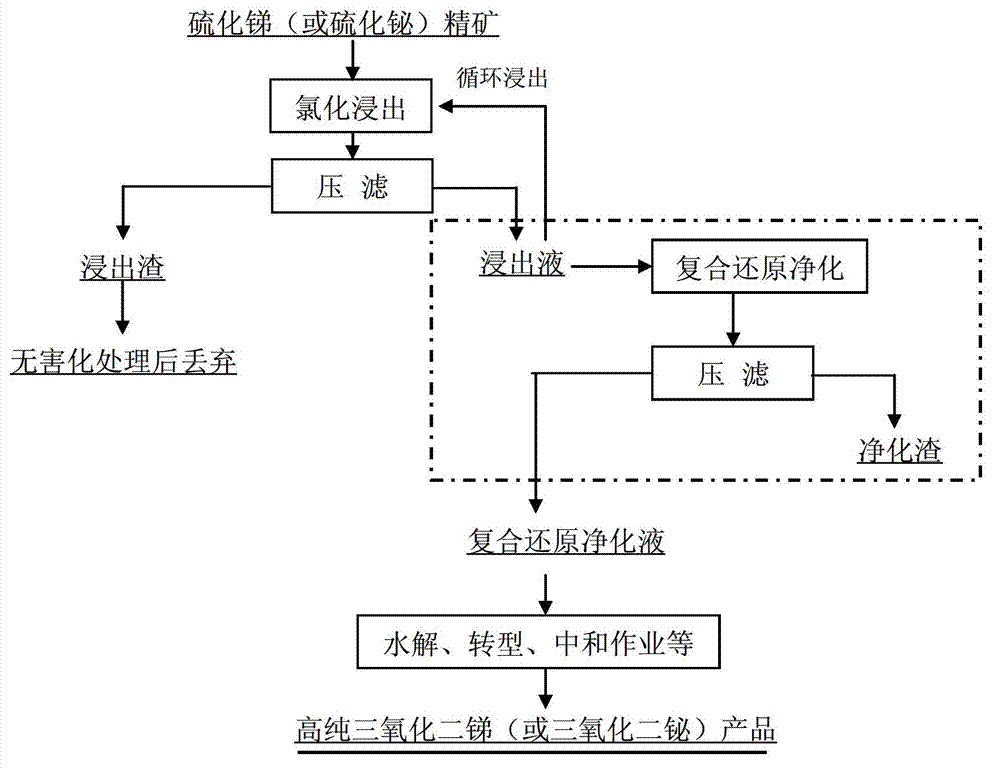

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The composition of antimony concentrate provided by a company in Hunan is: Sb 37.31%, Fe 13.68%, SiO 2 6.33%, Pb 4.6%, S 26.5%, As 2.1%.

[0051] Take 100g of the above antimony concentrate powder, when the liquid-solid ratio (ml / g) is 5:1, and the acidity of hydrochloric acid is 4.5mol L -1 , oxidizing agent Cl 2 The amount of addition (in Sb 2 S 3 consumption) is twice the theoretical amount, and the leaching temperature is 80°C. After leaching for 120 minutes, cool, clarify, filter and separate, wash the filter residue with 1:1 hydrochloric acid 100ml as the washing liquid, combine the washing liquid and the filtrate, and dry the filter residue. Weigh dry. The antimony content in the filtrate and filter residue was analyzed, and the leaching rate of antimony was 98.7% (liquid meter) / 99.5% (residue meter).

[0052] Analyze the content of the main impurity components in the filtrate such as lead, arsenic, etc., add a composite reduction purifying agent of 1.2 tim...

Embodiment 2

[0054] The composition of bismuth concentrate provided by a company in Hunan is: Bi 45.1%, Fe 11.28%, SiO 2 4.13%, Pb 2.6%, S 22.5%, As 1.1%.

[0055] Take 1000g of the above-mentioned bismuth concentrate powder, when the liquid-solid ratio (ml / g) is 4:1, and the acidity of hydrochloric acid is 4.0mol L -1 , Oxidant NaClO 3 The amount of addition (by Bi 2 S 3 consumption) is 2.5 times of the theoretical amount, and the leaching temperature is 90°C. After leaching for 90 minutes, cool, clarify, filter and separate, wash the filter residue with 1:1 hydrochloric acid 500ml as the washing liquid, combine the washing liquid and the filtrate, and dry the filter residue. Weigh dry. Analyze the bismuth content in filtrate and filter residue, obtain the leaching rate of bismuth 97.9% (liquid meter) / 98.6% (residue meter).

[0056] Analyze the main impurity components in the filtrate such as the content of lead, arsenic etc., add the composite reducing purifying agent of 2 times of...

Embodiment 3

[0058]The composition of antimony concentrate provided by a company in Hunan is: Sb 27.11%, Fe 19.22%, SiO 2 6.33%, Pb 14.6%, S 16.5%, As 5.1%.

[0059] Take 10Kg of the above antimony concentrate powder, when the liquid-solid ratio (ml / g) is 4:1, and the acidity of hydrochloric acid is 5mol L -1 , oxidizing agent Cl 2 The amount of addition (in Sb 2 S 3 consumption) is 3 times of the theoretical amount, and the leaching temperature is 85°C. After leaching for 180 minutes, cool, clarify, filter and separate, wash the filter residue with 1:1 hydrochloric acid 1000ml as the washing liquid, combine the washing liquid and the filtrate, and dry the filter residue. Weigh dry. The antimony content in the filtrate and filter residue was analyzed, and the leaching rate of antimony was 98.2% (liquid meter) / 98.9% (residue meter).

[0060] Analyze the content of the main impurity components in the filtrate such as lead, arsenic, etc., add a composite reduction purifying agent of 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com