PVDF (polyvinylidene fluoride) film modified with nano-titanium dioxide and preparation method for PVDA film

A nano-titanium dioxide, titanium dioxide technology, applied in the field of functional film and its preparation, can solve the problems of poor bonding performance, poor dispersion effect, material mechanical properties decline, etc., and achieve the goal of reducing pollution, simple preparation method and high grafting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

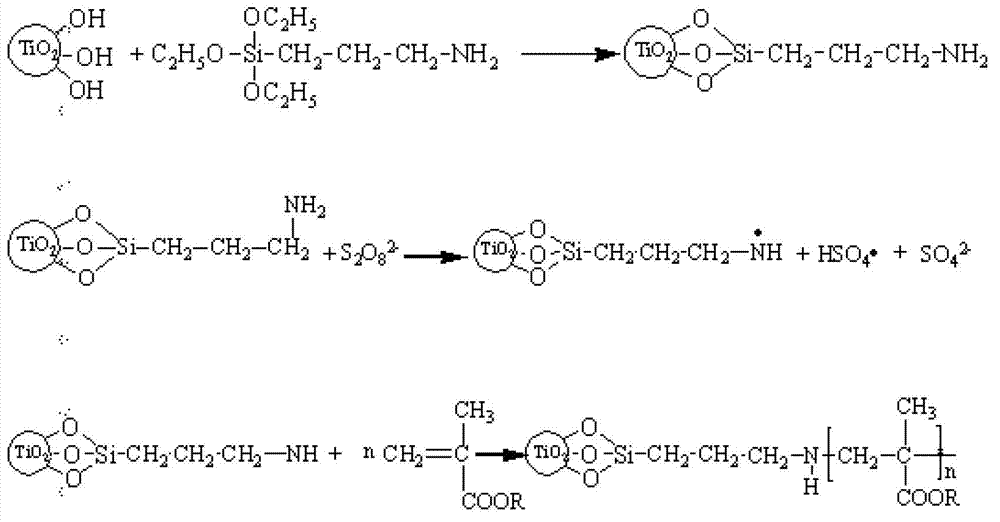

Method used

Image

Examples

Embodiment 1

[0025] Nano-TiO 2 The preparation method of surface-grafted polyfluorine-containing acrylate, specifically: in the reaction kettle, sequentially add 10 parts of dried nano-TiO 2 (particle size 1um), 100 parts of xylene and 5 parts of γ-aminopropyltriethoxysilane, mechanically stirred for 8 hours. After the reaction, filter, wash with absolute ethanol, and dry in vacuum. Weigh 8 parts of nano-TiO treated with silane 2 Put it in the reaction kettle, add 100 parts of distilled water and 5 parts of 0.5mol / L sodium hydroxide solution in sequence, slowly raise the temperature to 70°C with mechanical stirring, and blow in nitrogen to remove the air in the reaction kettle (the time is about 30min), Add 0.25 parts of ammonium persulfate, and slowly drop 50 parts of dodecafluoroheptyl methacrylate (drip within 30 minutes), and react for 2 hours. Add the remaining 0.25 parts of ammonium persulfate and continue the reaction for 8 hours. After the reaction, the product is vacuum filtere...

Embodiment 2

[0034] Nano-TiO 2 The preparation method of surface-grafted polyfluorine-containing acrylate, specifically: in the reaction kettle, sequentially add 10 parts of dried nano-TiO 2 (Particle size is 5um), 100 parts of xylene and 10 parts of γ-aminopropyltriethoxysilane, mechanically stirred for 9 hours. After the reaction, filter, wash with absolute ethanol, and dry in vacuum. Weigh 8 parts of nano-TiO treated with silane 2Put it in the reaction kettle, add 100 parts of distilled water and 5 parts of 0.5mol / L sodium hydroxide solution in sequence, slowly raise the temperature to 70°C with mechanical stirring, and blow in nitrogen to remove the air in the reaction kettle (the time is about 30min), Add 0.5 parts of ammonium persulfate, and slowly add 75 parts of dodecafluoroheptyl acrylate dropwise (dropping within 45 minutes), and react for 2 hours. Add the remaining 0.5 parts of ammonium persulfate and continue the reaction for 8 hours. After the reaction, the product is vacuu...

Embodiment 3

[0042] Nano-TiO 2 The preparation method of surface-grafted polyfluorine-containing acrylate, specifically: in the reaction kettle, sequentially add 7.5 parts of dried nano-TiO 2 (particle size is 2.5um), 100 parts of xylene and 10 parts of γ-aminopropyltriethoxysilane, mechanically stirred for 9 hours. After the reaction, filter, wash with absolute ethanol, and dry in vacuum. Weigh 8 parts of nano-TiO treated with silane 2 Put it in the reaction kettle, add 100 parts of distilled water and 5 parts of 0.5mol / L sodium hydroxide solution in sequence, slowly raise the temperature to 70°C with mechanical stirring, and blow in nitrogen to remove the air in the reaction kettle (the time is about 30min), Add 0.35 parts of ammonium persulfate, and slowly drop 50 parts of hexafluorobutyl acrylate and 50 parts of hexafluorobutyl methacrylate (drip within 60 minutes), and react for 2 hours. Add the remaining 0.35 parts of ammonium persulfate and continue the reaction for 8 hours. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com