Treatment method of mine pothole waste water containing heavy metals

A treatment method and heavy metal technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve secondary pollution, difficulty in wastewater reuse, difficult reuse of treated water, etc. problem, to achieve the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

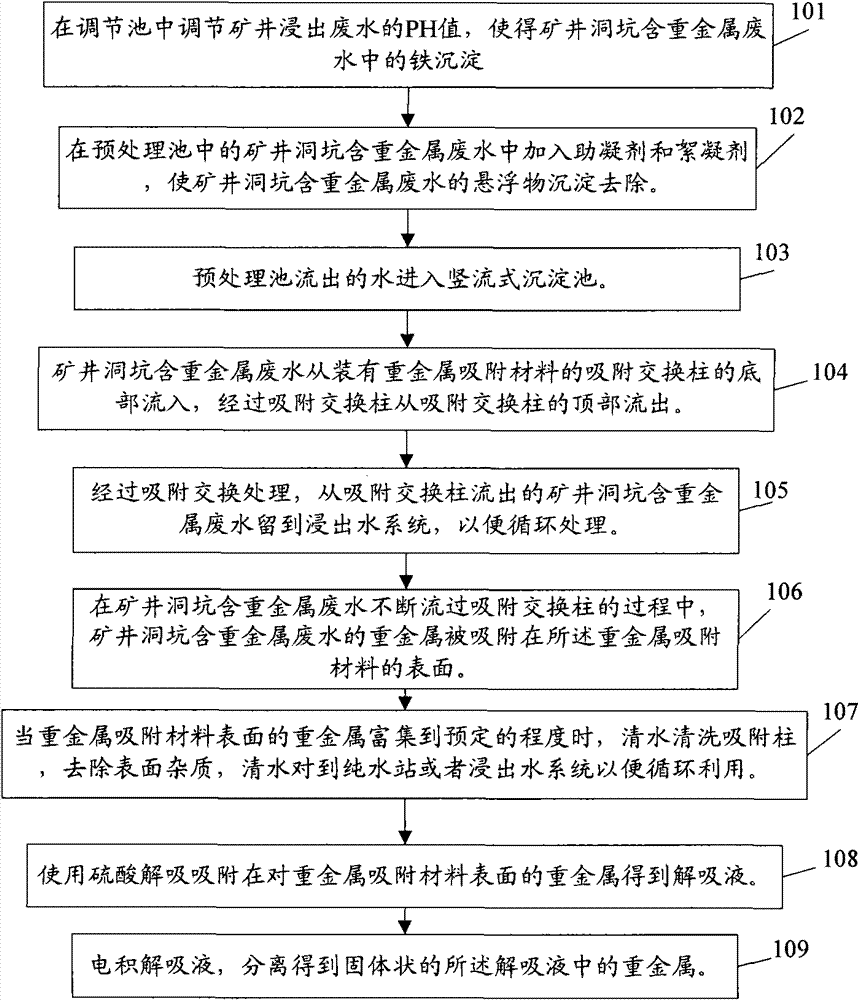

[0045] figure 1 It is a schematic flowchart of a method for treating heavy metal-containing wastewater from mine pits provided in this embodiment. It mainly includes the following process steps:

[0046] Step 101: Adjusting the pH value of the mine leaching wastewater in the regulating tank, so that the iron in the mine pit wastewater containing heavy metals is precipitated.

[0047]Because the heavy metal wastewater in mine pits is relatively turbid and contains various impurities and various possible metal elements, before carrying out the main treatment of this embodiment, carry out the pretreatment of this step and adjust the pH value (adjust to a pH value of 3 -5), so that the iron is removed by precipitation, so as to reduce the impact of iron on the exchange and adsorption of heavy metal exchange substances when the heavy metal-containing wastewater in the mine pit passes through the adsorption exchange column.

[0048] After the PH adjustment of the adjustment pool, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com