Suede preparation method of metallurgical-grade single crystal and mono-like silicon

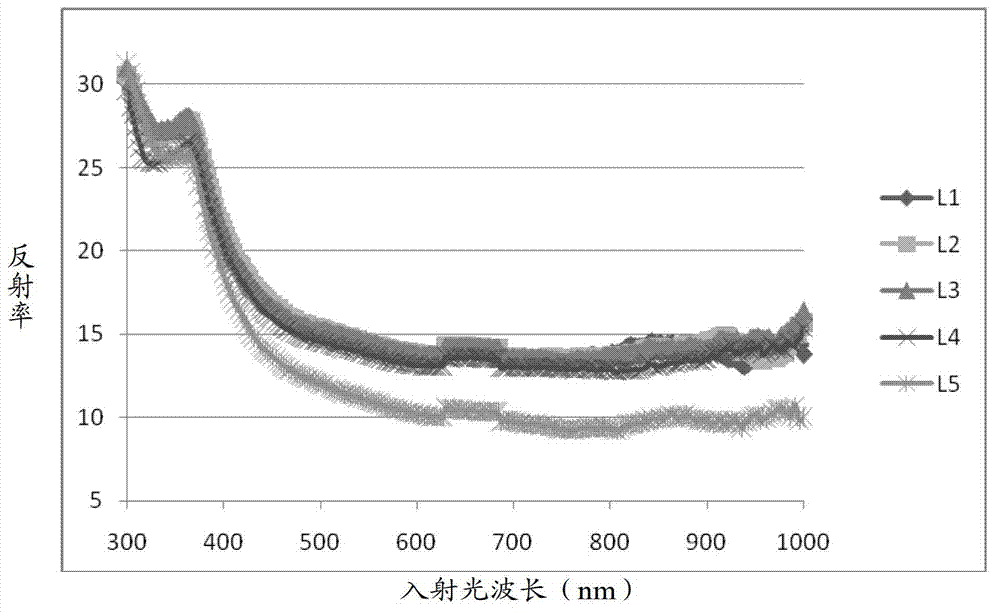

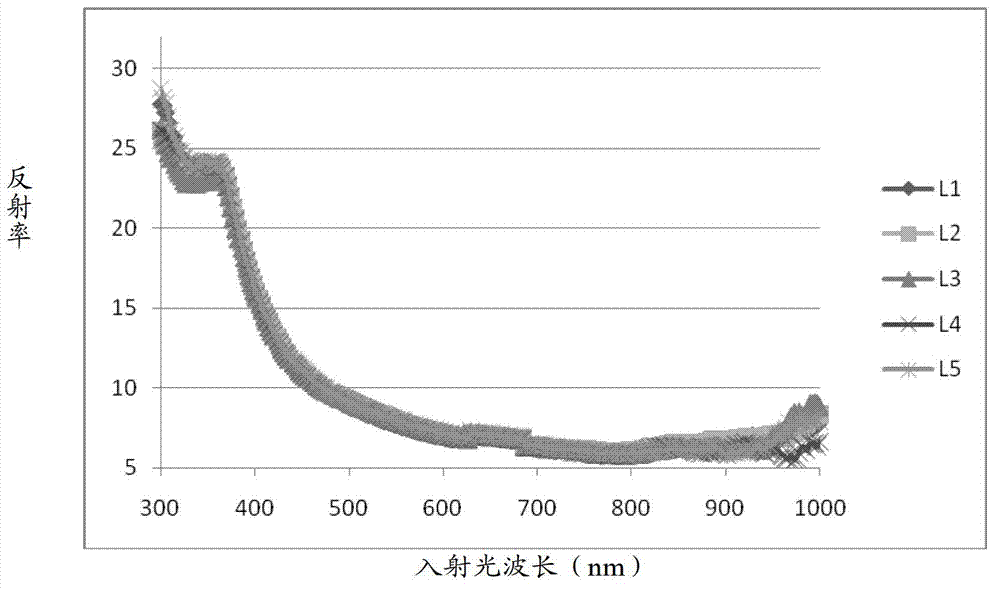

A kind of monocrystalline silicon-like, metallurgical grade technology, applied in the field of suede preparation of silicon wafers, can solve the problems of difficulty in making suede, process pollution, pollution of the suede groove, etc., to achieve uniform suede effect, reduce low energy potential points, The effect of improving surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail through the following examples, but the examples are not intended to limit the protection scope of the present invention.

[0030] refer to figure 1 The method for preparing the textured surface of metallurgical grade single crystal and single crystal silicon of the present invention includes a pretreatment process and a conventional texturing process. The silicon wafer is a metallurgical grade silicon wafer with high impurity content and serious surface pollution.

[0031] The preprocessing process is performed first.

[0032] (1) Configure the pretreatment solution. The pretreatment solution is composed of potassium hydroxide with a mass percentage concentration of 0.5%-10%, hydrogen peroxide water with a mass percentage concentration of 2.5%-8%, and deionized water with a mass percentage concentration of 82%-97%.

[0033] (2) Carry out the pretreatment process. Place the silicon wafer to be textured after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com