Method for preparing micron-order phase-change microemulsion

A phase change microemulsion and micron-scale technology, which is applied in the field of preparation of micron-scale phase change microemulsion, can solve the problems of improving the supercooling phenomenon of non-microemulsion, and achieve the effects of overcoming poor stability, reducing volume and reducing supercooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

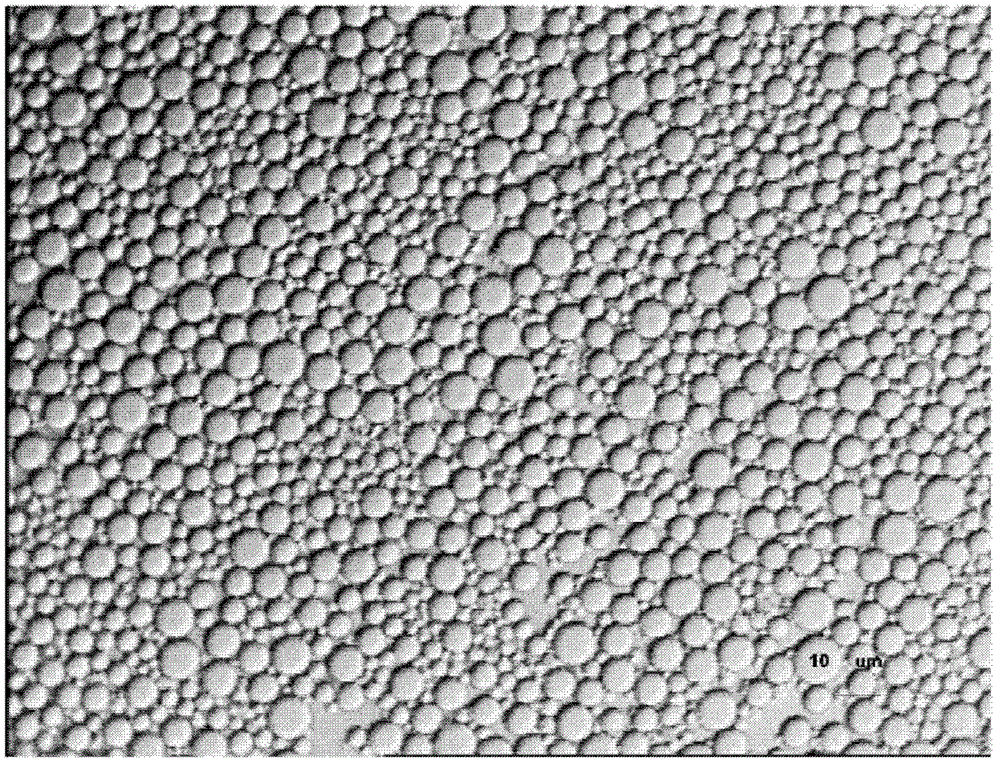

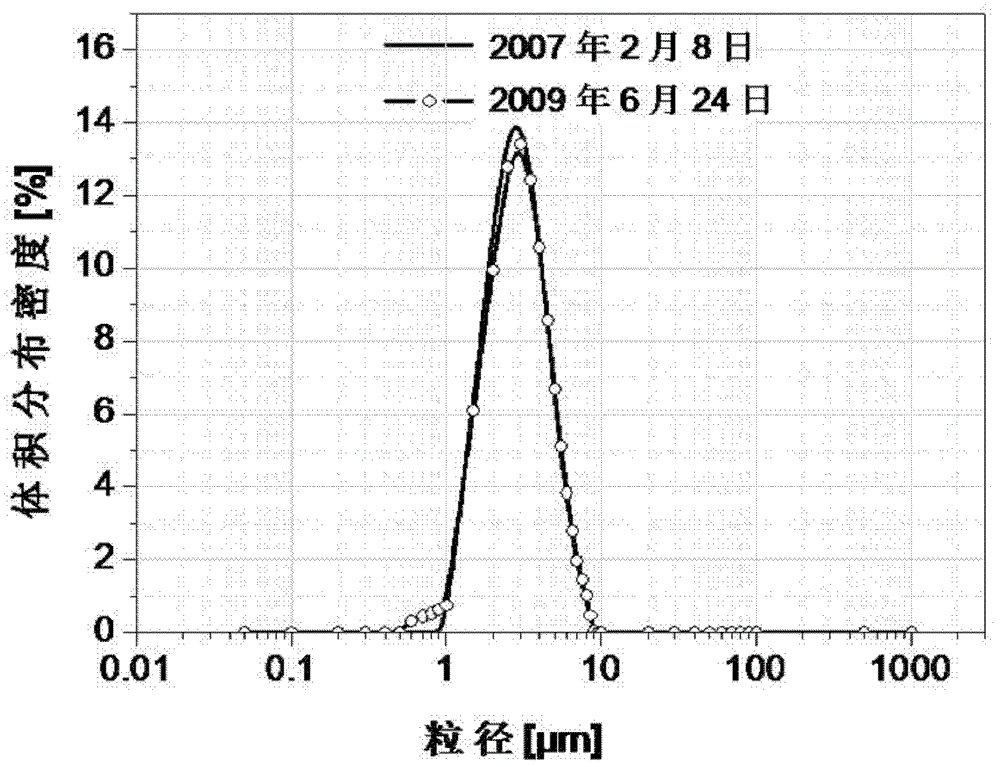

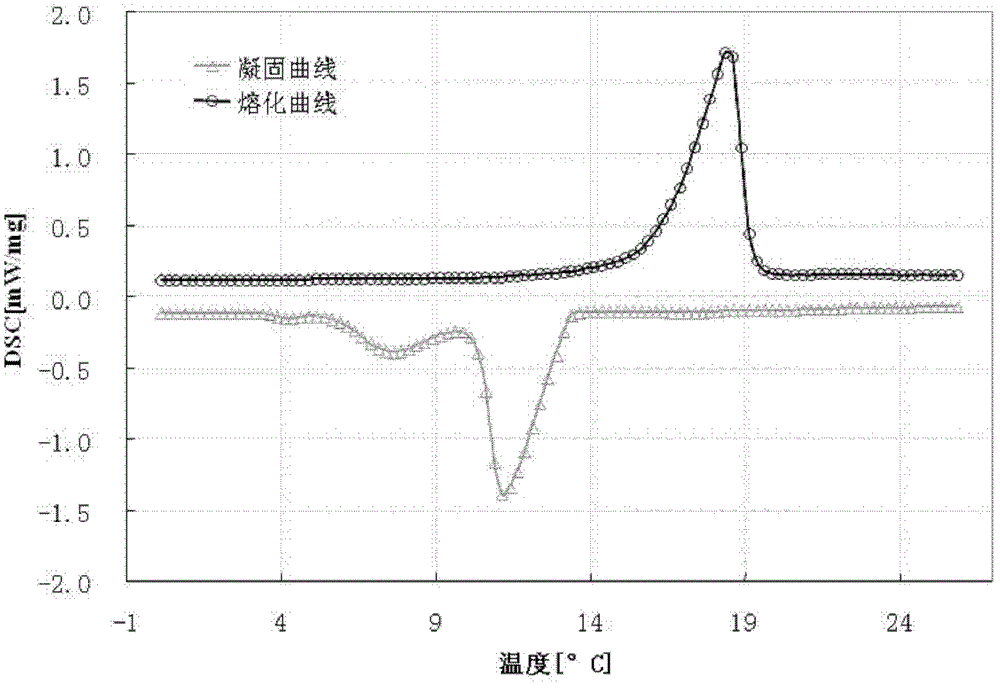

[0036] Add 1.5 g of paraffin wax with a melting point of 35° C. into 15 g of n-tetradecane, heat to 50° C. and stir to completely melt the solid matter to form a dispersed phase. Add 1.5 g of polyoxyethylene sorbitan monooleate 40 (Tween40) into a mixture of 26 g of propylene glycol (antifreeze) and 56 g of water, heat to 50° C. and stir to form a continuous phase. The dispersed phase is added to the continuous phase with constant stirring to form a pre-emulsion. Stir the pre-emulsion with a high-speed homogenizer, and emulsify it for 8 minutes at a speed of 20,000 rpm. The product is an opaque milky white phase-change microemulsion, wherein the weight ratio of the phase-change material is 15%.

Embodiment 2

[0038]Add 0.5 g of zinc oxide nanoparticles (average particle size of 0.1 μm) into 35 g of n-tetradecane, heat to 40° C. and stir to completely melt the solid matter to form a dispersed phase. Add 3.5 g of didodecyldimethylammonium bromide (DDAB) into a mixture of 15 g of ethanol (antifreeze) and 46 g of water, heat to 40° C. and stir to form a continuous phase. The dispersed phase is added to the continuous phase with constant stirring to form a pre-emulsion. Use a high-speed homogenizer to stir the pre-emulsion, and emulsify for 10 minutes at a speed of 22000 rpm. The product is an opaque milky white phase-change microemulsion, wherein the weight ratio of the phase-change material is 35%.

Embodiment 3

[0040] Add 2 g of stearic acid into 50 g of n-pentadecane, heat to 80° C. and stir to completely melt the solid matter to form a dispersed phase. Add 3.5 g of sodium dodecyl sulfate (SDS) to 44.5 g of water, heat to 80° C. and stir to form a continuous phase. The dispersed phase is added to the continuous phase with constant stirring to form a pre-emulsion. Use a high-speed homogenizer to stir the pre-emulsion, and emulsify it at a speed of 25000 rpm for 10 minutes. The product is an opaque milky white phase-change microemulsion, wherein the weight ratio of the phase-change material is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com