Mesoporous manganese dioxide material, preparation method thereof and supercapacitor

A manganese dioxide and mesoporous technology, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of complicated operation and complicated process, and achieve the effect of large BET specific surface area, simple preparation method and high specific capacitance per unit specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of mesoporous manganese dioxide material, comprising the following steps:

[0039] Potassium permanganate solution and ascorbic acid solution are mixed and reacted under the condition of stirring to obtain mesoporous manganese dioxide material, and the molar ratio of the potassium permanganate to the ascorbic acid is 10: (1-8).

[0040] The invention uses potassium permanganate and ascorbic acid as raw materials to prepare the mesoporous manganese dioxide material, the method is simple and fast, and is suitable for industrial production.

[0041] According to the present invention, the concentration of the potassium permanganate solution is preferably 0.1mol / L to 2mol / L, more preferably 0.3mol / L to 1mol / L; the concentration of the ascorbic acid solution is preferably 0.1mol / L to 2mol / L, more preferably 0.3 mol / L to 1 mol / L.

[0042]In the present invention, the ascorbic acid solution is preferably added dropwise...

Embodiment 1

[0061] Prepare 0.4mol / L potassium permanganate aqueous solution and 0.4mol / L ascorbic acid aqueous solution respectively, add 30mL ascorbic acid aqueous solution dropwise to 100mL potassium permanganate aqueous solution under the condition of rapid stirring, continue stirring for 30min after the dropwise addition, centrifuge After separation, a dark brown precipitate was obtained, which was alternately washed with water and ethanol for 5 times, and then dried in a vacuum oven at 60° C. for 12 hours to obtain a manganese dioxide material.

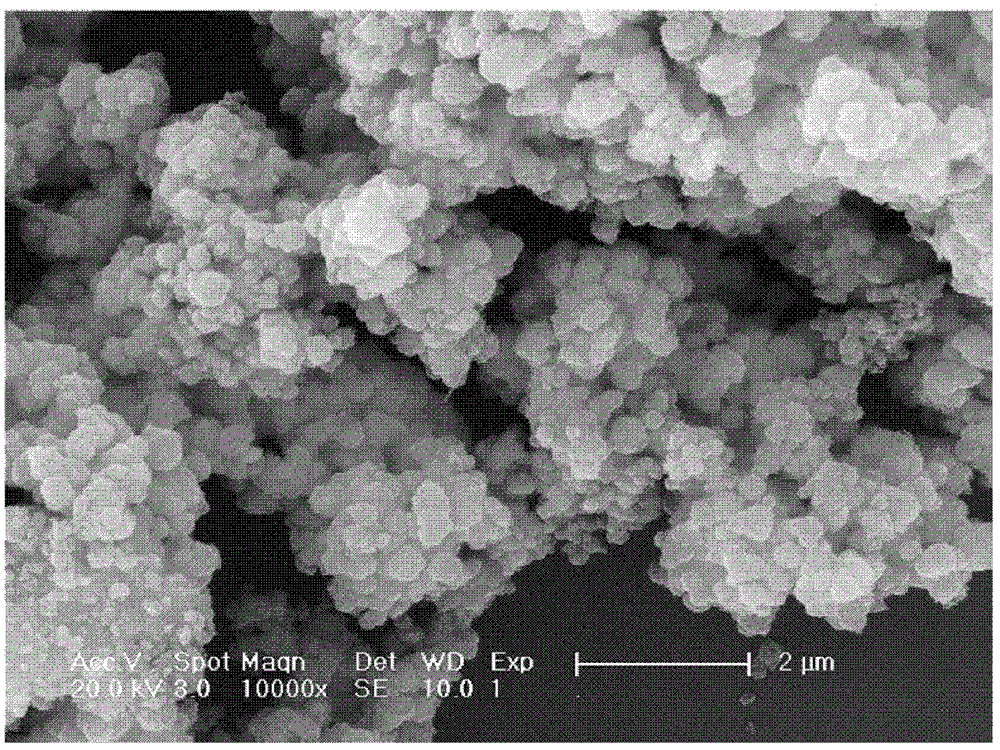

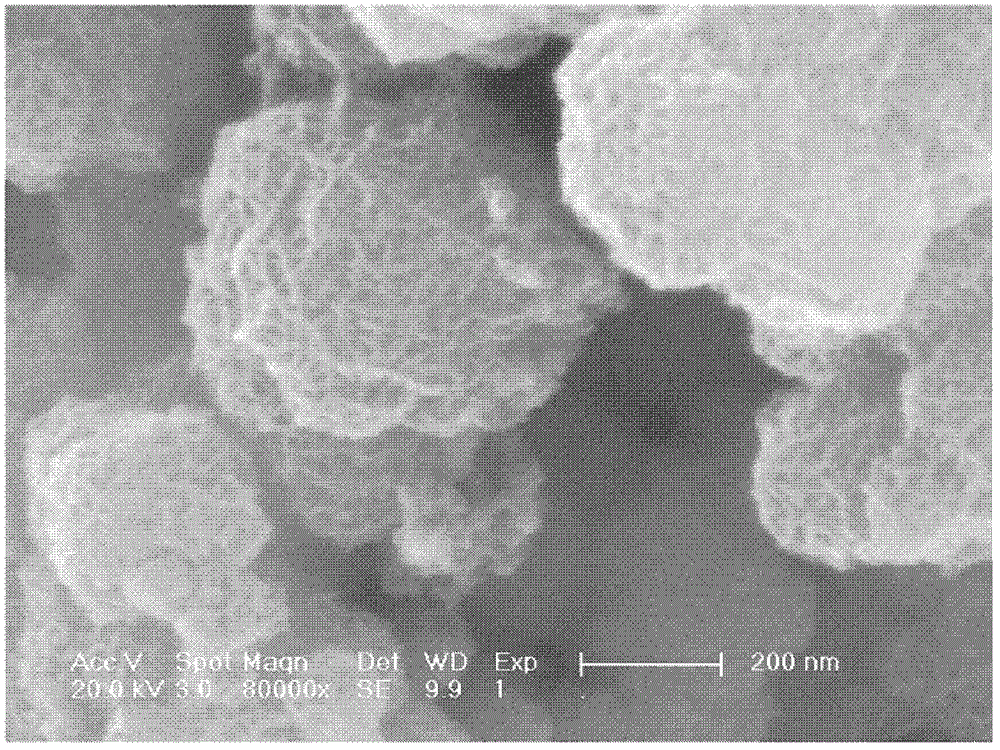

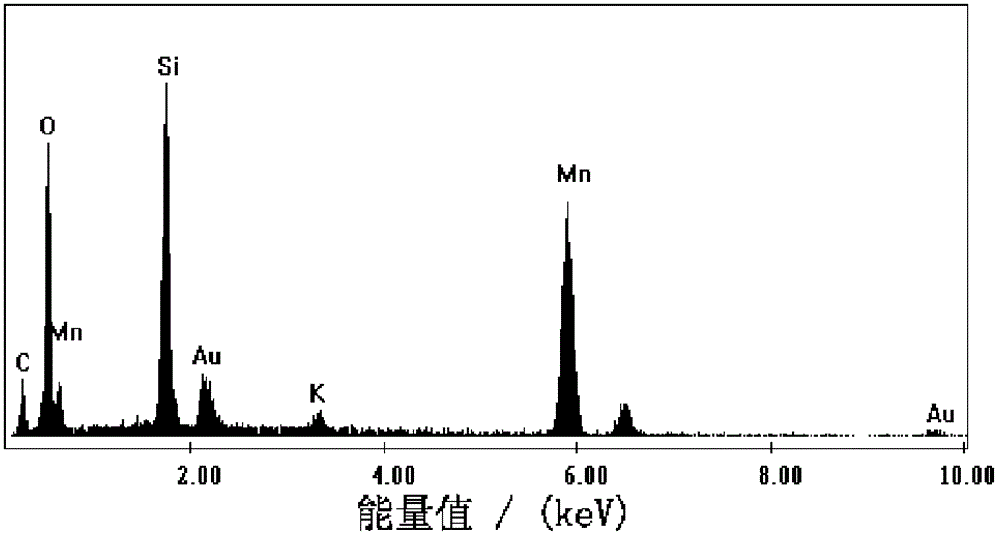

[0062] The XL-30ESEM type electron microscope of Philips that adopts the X-ray spectrum analyzer that has assembled energy dispersive is analyzed to described manganese dioxide material, and accelerating voltage is 15kV, and the result sees figure 1 with figure 2 , figure 1 A scanning electron microscope photo enlarged 10,000 times for the manganese dioxide material prepared in Example 1 of the present invention, figure 2 For the mangane...

Embodiment 2

[0069] Mix 6 mg of the manganese dioxide material prepared in Example 1 with 3 mg of the conductive adhesive purchased from Shanghai Hanbo Industrial Co., Ltd., model HB-012, and evenly coat it on the stainless steel battery current collector and press it into a film as a working electrode. Platinum The electrode is the counter electrode, the Ag / AgCl (saturated KCl) electrode is the reference electrode, and 20 mL of lithium sulfate solution with a concentration of 0.05mol / L, 0.1mol / L, 0.25mol / L, 0.5mol / L and 1mol / L , sodium sulfate solutions with concentrations of 0.05mol / L, 0.1mol / L, 0.25mol / L, 0.5mol / L and 1mol / L and concentrations of 0.05mol / L, 0.1mol / L, 0.25mol / L, 0.5mol / L and 0.65mol / L potassium sulfate solution as the electrolyte, using CH1700d electrochemical workstation in the voltage range of 0 ~ 1V, respectively at 1mVs -1 , 2mVs -1 , 5mVs -1 , 8mVs -1 , 10mVs -1 , 15mVs -1 , 20mVs -1 , 30mVs -1 , 50mVs -1 Downsweep cyclic voltammetry curve at the scan rate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com