Vibrating wire-feeding surfacing method

A technology of wire feeding and surfacing layer, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems affecting the quality and efficiency of industrialized production, decrease in deposition efficiency, low welding deposition rate, etc. Welding efficiency, the effect of reducing welding hot cracks and porosity, and improving the performance of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Taking the pipe end of bimetallic composite pipe as an example, the vibrating wire feeding surfacing welding method is realized by the following steps:

[0019] (1) Preheating treatment

[0020] Carry out preheating treatment to the welding end of the bimetallic composite pipe 1, and the preheating temperature is 75°C;

[0021] (2) Welding

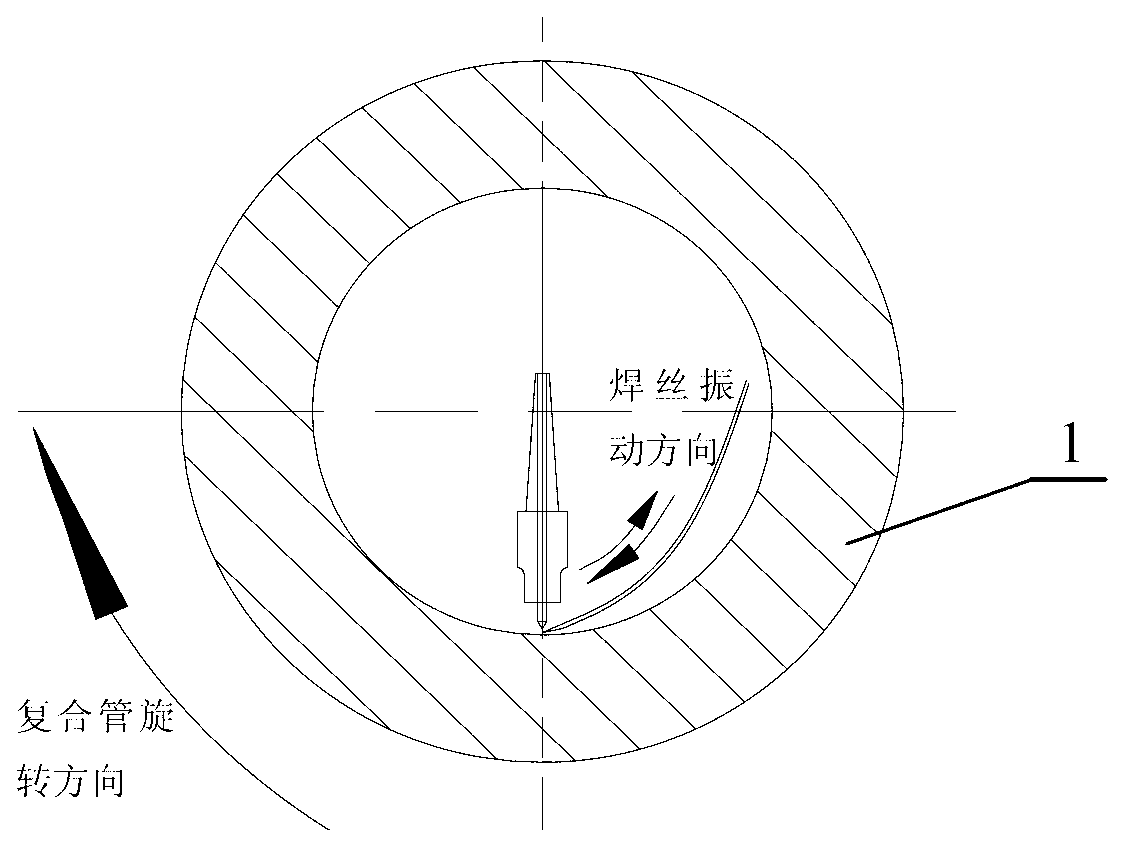

[0022] Turn on the ordinary welding machine, shielding gas and commonly used wire feeding device, adjust the welding current to 250A, and the voltage to 15V. Under the shielding gas of argon gas with a purity of 99.999%, the welding torch is driven by the cross slide table of the welding machine. Swing left and right, spread the weld bead evenly, automatically adjust the up and down position of the welding torch according to the length of the welding arc, driven by the vibration drive device of the wire feeding device, the welding wire vibrates back and forth along the wire feeding direction, see figure 1 , the welding heat input ...

Embodiment 2

[0025] Taking the pipe end of bimetallic composite pipe as an example, the vibrating wire feeding surfacing welding method is realized by the following steps:

[0026] (1) Preheating treatment

[0027] Carry out preheating treatment to the welding end of the bimetal composite pipe 1, and the preheating temperature is 50°C;

[0028] (2) Welding

[0029] Turn on the ordinary welding machine, shielding gas and commonly used wire feeding device, adjust the welding current to 240A, and the voltage to 14V. Under the shielding gas with a purity greater than 99.991% argon, the welding torch is driven left and right by the cross slide table of the welding machine Swing, the weld bead is evenly spread out, and the up and down position of the welding torch is automatically adjusted according to the length of the welding arc. Driven by the vibration drive device of the wire feeding device, the welding wire vibrates back and forth along the wire feeding direction, and the welding heat inp...

Embodiment 3

[0031] Taking the pipe end of bimetallic composite pipe as an example, the vibrating wire feeding surfacing welding method is realized by the following steps:

[0032] (1) Preheating treatment

[0033] Carry out preheating treatment to the welding end of the bimetal composite pipe 1, and the preheating temperature is 95°C;

[0034] (2) Welding

[0035] Turn on the ordinary welding machine, shielding gas and commonly used wire feeding device, adjust the welding current to 270A, and the voltage to 16V. Under the shielding gas with a purity greater than 99.995% argon, the welding torch is driven left and right by the cross slide table of the welding machine Swing, the welding bead is evenly spread out, and the up and down position of the welding torch is automatically adjusted according to the length of the welding arc. Driven by the vibration drive device of the wire feeding device, the welding wire vibrates back and forth along the wire feeding direction, and the welding heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com