Conductive silver adhesive for high-power LED (light-emitting diode) and preparation method and curing and using method thereof

A conductive silver glue, high-power technology, applied in the direction of conductive adhesives, circuits, adhesives, etc., can solve the problems of poor solubility and fusibility, unsatisfactory anti-aging performance, poor flame retardancy, etc., and achieve high temperature resistance Excellent, good application prospects, strength and other indicators to enhance the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

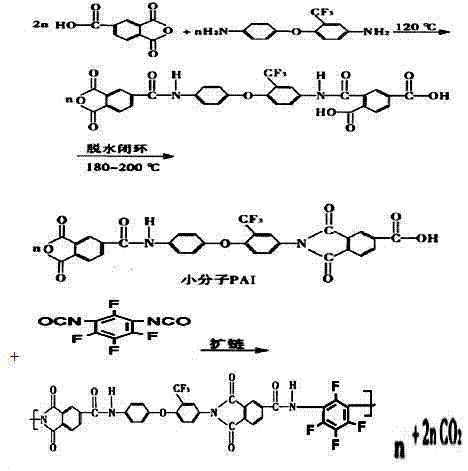

Method used

Image

Examples

Embodiment 1

[0025] Add 10g of epoxy resin E-44 and 2.2g of fluorine-containing polyamideimide to an appropriate amount of N,N'-dimethylacetamide, stir and dissolve evenly, add 0.8g of diaminodiphenylmethane, and Add 2g of polyimide, add 80g of conductive silver powder, 4g of carbon fiber with a length of 10 microns, 1g of KH550 coupling agent, grind and mix evenly, heat at 170°C for one hour, and heat at 190°C for one hour to cure. The tensile strength is 120MPa, and the resistance value 12 μΩ·cm, thermal decomposition temperature 402℃.

[0026] The curing agent is one or more mixtures of amino-terminated polyimides, amino-terminated polyamide-imides, polyamines, polybasic anhydrides and bismaleimide curing agents.

Embodiment 2

[0028] The similarities between this example and Example 1 will not be repeated. The difference is that 10g of phenolic modified epoxy resin F-44 and 7g of fluorine-containing polyamideimide are added to an appropriate amount of N,N'-two In methyl acetamide, dissolve evenly, add 8g of amino-terminated polyamideimide, 65g of conductive silver powder, 9g of carbon fiber, 1g of KH560 coupling agent, grind and mix evenly, heat at 170°C for one hour, and heat at 190°C for one hour to cure. The tensile strength is 160MPa, the resistance value is 14 μΩ·cm, and the thermal decomposition temperature is 414°C.

Embodiment 3

[0030] The similarities between this example and Example 1 will not be repeated. The difference is that 10g of cycloaliphatic epoxy resin and 7.7g of fluorine-containing polyamideimide are added to an appropriate amount of N,N'-dimethyl In acetamide, dissolve evenly and add maleic anhydride 0.8g, amino-terminated polyetherimide 2g, conductive silver powder 70g, carbon fiber 9g, KH550 coupling agent 0.5g, grind and mix evenly, keep warm at 170°C for one hour, 190°C ℃ for one hour to cure, the tensile strength is 155MPa, the resistance value is 13 μ Ω cm, and the thermal decomposition temperature is 412℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com