Three-dimensional continuous graphene network composite material and its preparation method

A composite material and graphene technology, applied in the field of nanomaterials, can solve the problems that affect the comprehensive performance of the three-dimensional graphene skeleton composite material, cannot be organically compounded with polymer materials, and the three-dimensional skeleton is difficult to keep intact, and achieves easy process control and equipment. The effect of low investment and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Use commercially available copper foam (purchased from Changsha Liyuan New Material Co., Ltd.) metal template as a catalyst, put it into a chemical vapor deposition reactor, feed 100 sccm hydrogen and 100 sccm argon, and start heating to 800 ° C after 60 minutes , feed 80sccm methane after 30 minutes at constant temperature, the reaction time is 30 minutes, stop passing methane after the reaction is over, turn off the electric furnace, and cool to room temperature naturally;

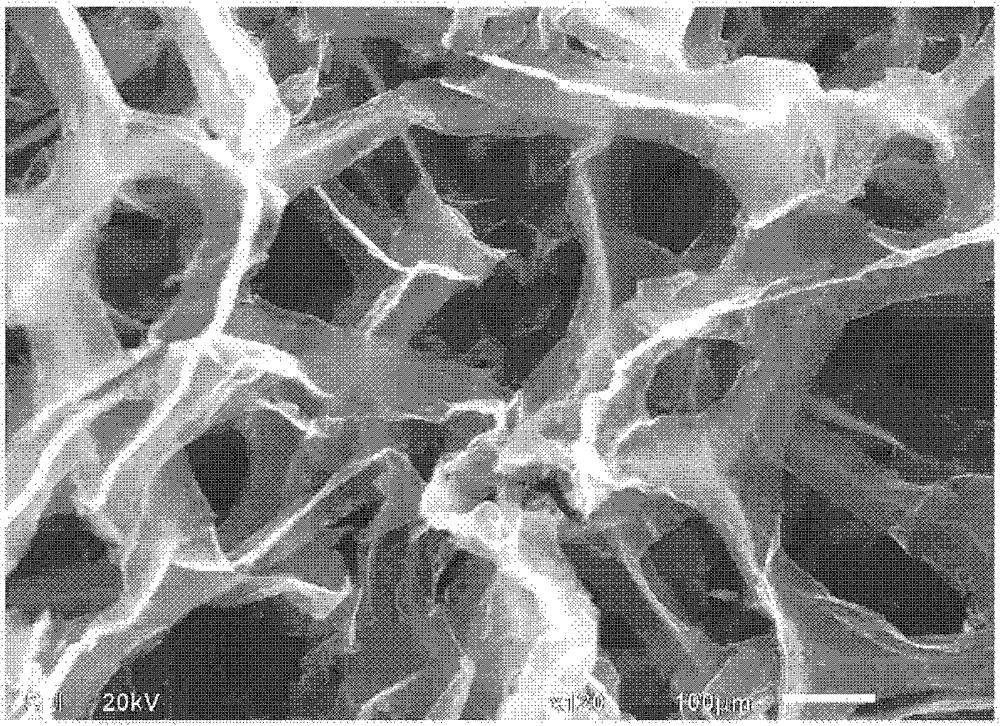

[0027] (2) Take the product obtained in step (1) in an aqueous solution of 4wt% polyvinyl alcohol, take it out and dry it at 100°C for 3 hours to deposit a layer of polyvinyl alcohol on its surface, put 100ml of 1M hydrochloric acid and 1M FeCl 3 Stir in the solution for 4 hours to remove metal copper and obtain a three-dimensional graphene / polyvinyl alcohol skeleton composite structure. The scanning electron microscope photo is as follows: figure 1 shown. If the polyvinyl alcohol support is ...

Embodiment 2

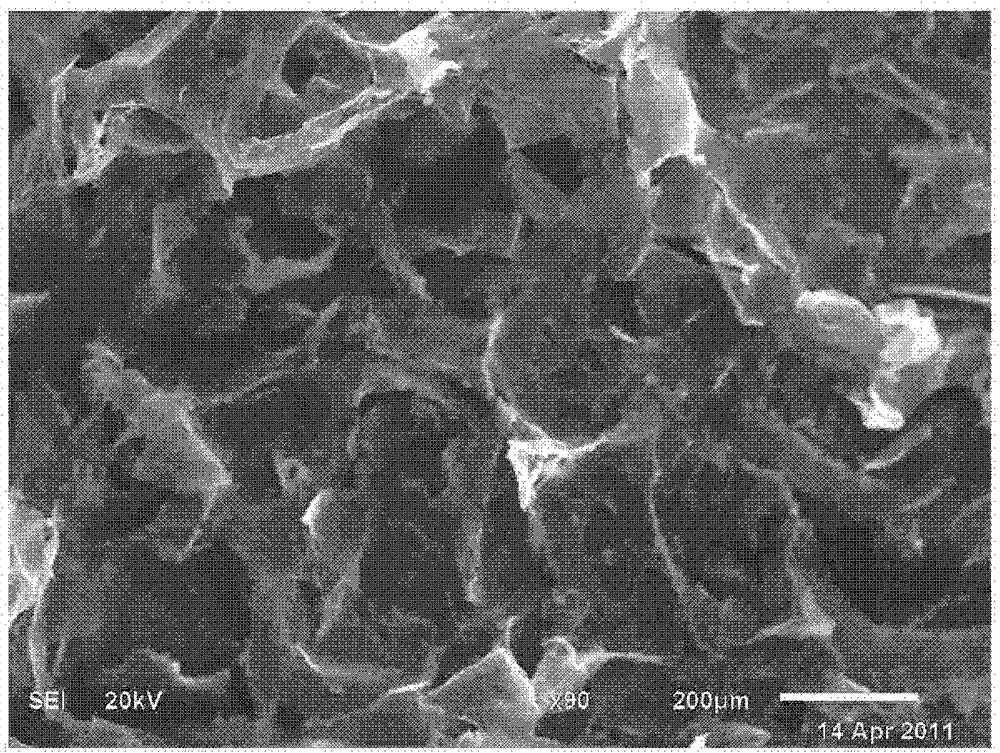

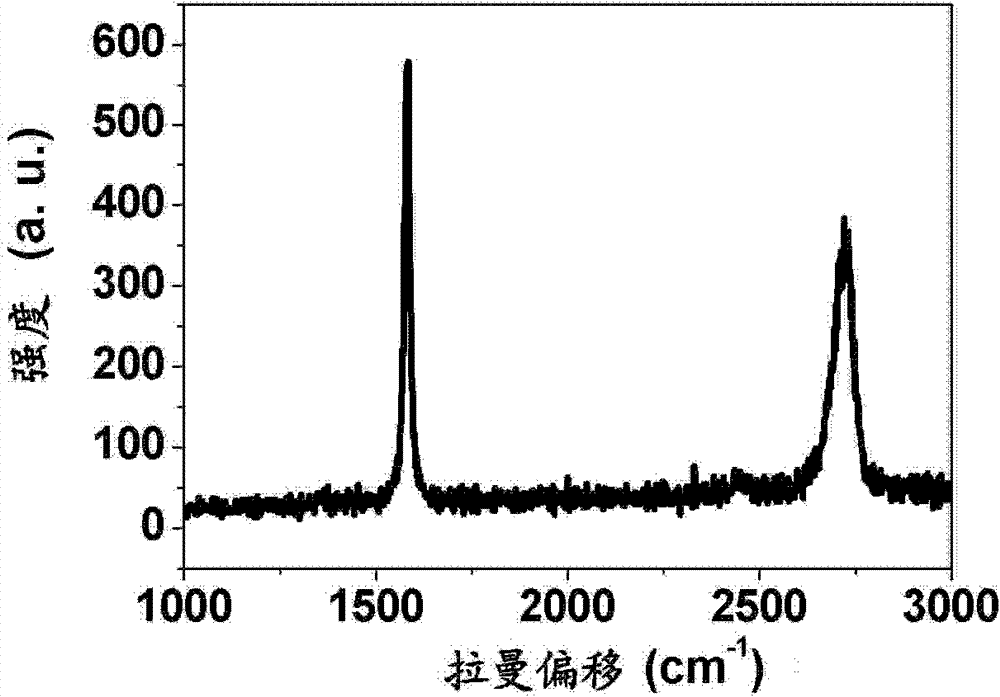

[0030] The preparation method is basically the same as in Example 1, except that the difference is: in step (1), nickel foam that is ultrasonically cleaned through ethanol, acetone and isopropanol is used as a catalyst, and it is immersed in N, N of polydimethylsiloxane. In two-dimethylformamide solution, obtain foam nickel / polydimethylsiloxane composite structure, pass through 100sccm hydrogen, 100sccm nitrogen, reaction time 30 minutes, Raman spectrum is as figure 2 As shown, the number of graphene layers is 3-10; in step (2), deposit one deck of polyvinylidene fluoride on the surface of foamed nickel, and use concentrated hydrochloric acid to remove foamed nickel; in step (5), 2wt% graphene three-dimensional framework Composite with polyvinylidene fluoride, the curing temperature is 60 ° C, and the curing time is 10 hours. The conductivity of the obtained graphene / polyvinylidene fluoride composite material is 15.3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com