Preparation method of titanium dioxide nano hollow ball

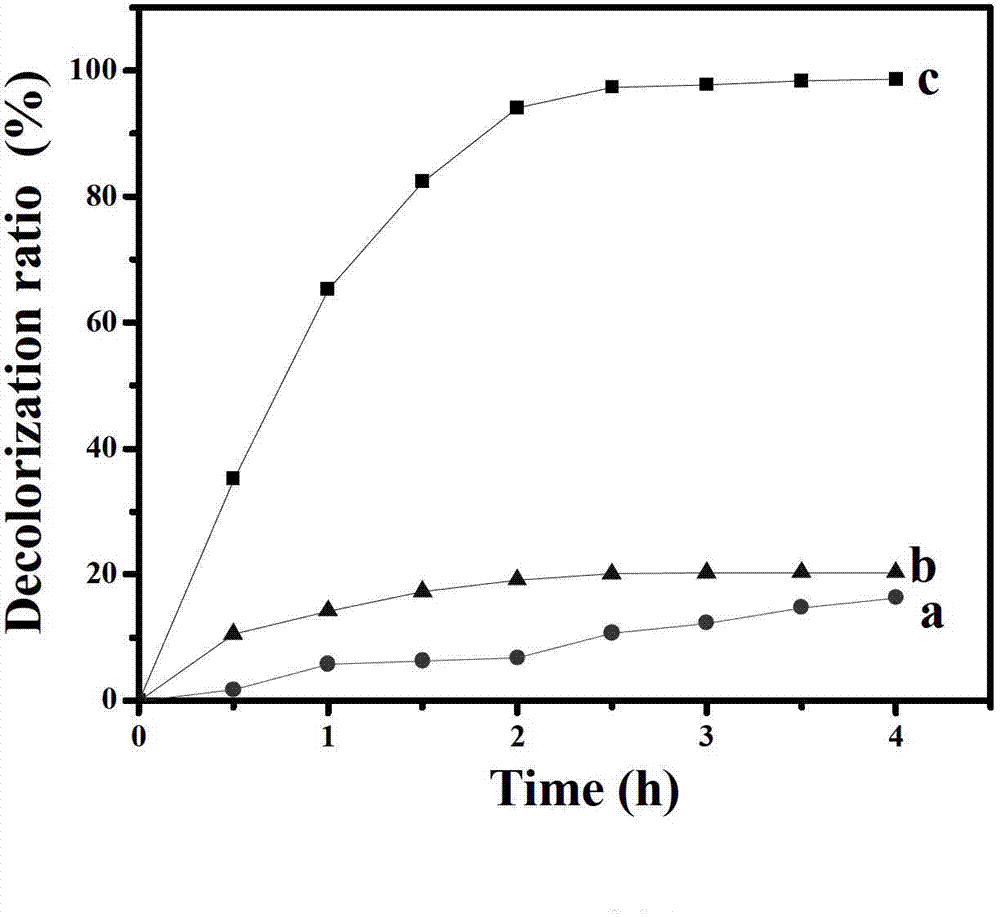

A titanium dioxide, hollow sphere technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of difficult washing process and product agglomeration, and achieves simple process, mild reaction conditions, and obvious photocatalytic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

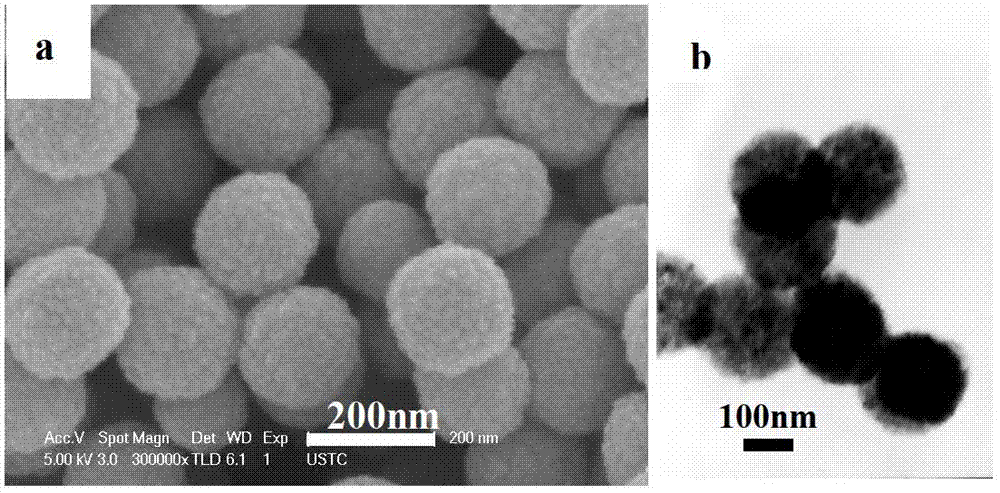

[0029] 1.5mmol CuSO 4 Add 100mL deionized water, then add 1~10g glucose, stir to dissolve into a transparent solution. Then add 1mL of 0.1M ammonia water, flocculent precipitation appears, then slowly add 10mL of Na(OH) solution with a concentration of 1~10M, and finally add 50mL of ascorbic acid with a concentration of 1~5g / L quickly, keep stirring for 1h, and centrifuge the precipitate. Wash and dry. Get Cu 2 O nanospheres. Depend on figure 1 It can be seen that the prepared Cu 2 The surface of the O nanosphere is rough, the diameter is about 200nm, the size is uniform, and the dispersion is good.

[0030] The prepared Cu 2 O nanospheres were ultrasonically dispersed in 20 mL of absolute ethanol, then 0.01–3 mL of tetra-n-butyl titanate was dissolved in 20 mL of absolute ethanol, and slowly added dropwise to the above Cu 2 O / ethanol suspension, magnetically stirred for 1 h. Add 20mL of V (water) / V (ethanol)=1~9:1 solution to the above solution, continue to stir for 1...

Embodiment 2

[0032] The Cu prepared in Example 1 2 O nanospheres were calcined at a temperature of 100-500°C for 1-4h to obtain CuO nanospheres of the same size, and the product was centrifuged and washed with distilled water.

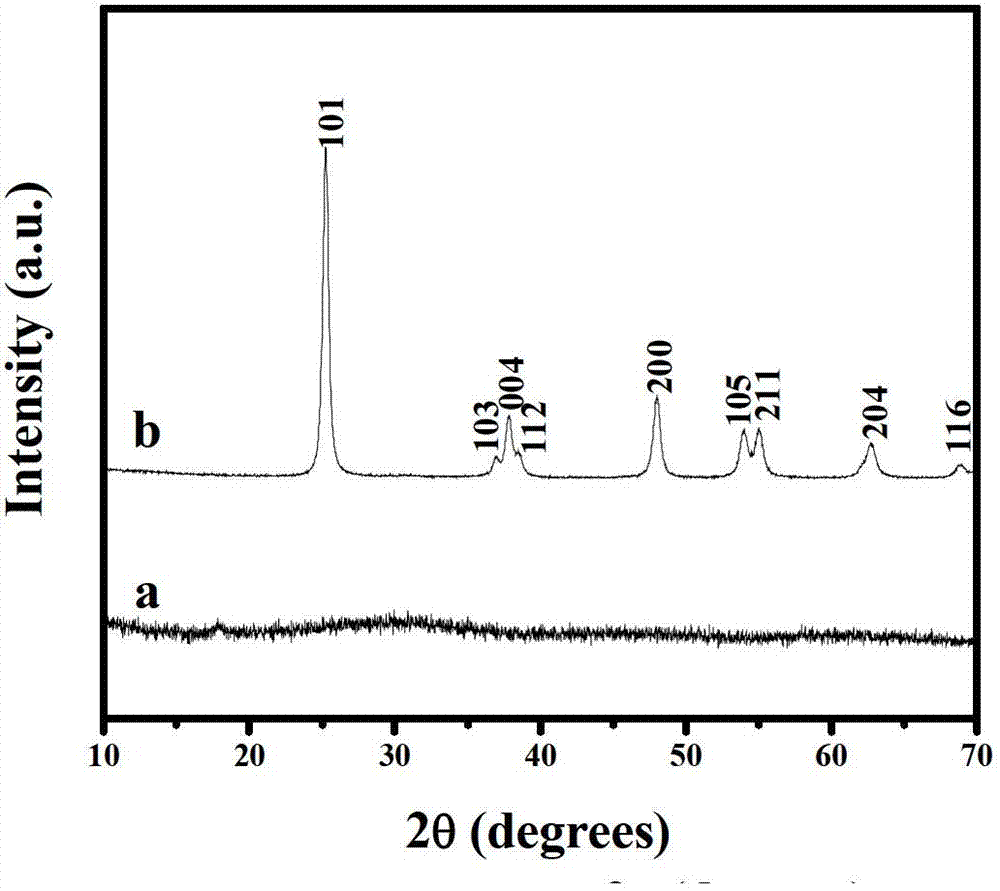

[0033] The prepared CuO nanospheres were ultrasonically dispersed in 20mL of absolute ethanol, then 0.01~3mL of tetra-n-butyl titanate was dissolved in 20mL of absolute ethanol, slowly added dropwise to the above CuO / ethanol suspension, and magnetically stirred for 1h . Add 20mL of V (water) / V (ethanol)=1~9:1 solution to the above solution, continue stirring for 1h, centrifuge, wash with ethanol, add to 1M sulfuric acid solution for etching and dissolving for 1~24h, After centrifugation and washing, amorphous titanium dioxide hollow spheres are obtained at room temperature. The product was calcined at 250-650°C for 6 hours to obtain anatase-type titanium dioxide hollow nanospheres with a high degree of crystallization.

Embodiment 3

[0035] Template Cu 2 The preparation method of O nanospheres is the same as in Example 1.

[0036] The prepared Cu 2 O nanospheres were ultrasonically dispersed in 20 mL of absolute ethanol, then 0.01–3 mL of tetraisopropyl titanate was dissolved in 20 mL of absolute ethanol, and the above Cu 2 O / ethanol suspension, magnetically stirred for 1 h. Add 20mL of V (water) / V (ethanol)=1~9:1 solution to the above solution, continue to stir for 1h, centrifuge, wash with ethanol, add to 1.5M hydrochloric acid solution for etching and dissolving for 1~24h , centrifuged and washed to obtain titanium dioxide hollow spheres at room temperature. The product was calcined at 250-650°C for 6 hours to obtain anatase-type titanium dioxide hollow nanospheres with a high degree of crystallization.

[0037] attached by figure 2 , 3 It can be seen that the synthesized titanium dioxide nano hollow spheres are anatase titanium dioxide with uniform size and good dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com