Spinning swelling solution used for preparation of ultra-high molecular weight colored polyethylene fiber and spinning stock solution

An ultra-high molecular weight, polyethylene fiber technology, applied in the preparation of spinning solution, adding pigments in spinning solution, single-component polyolefin rayon, etc., can solve the problem of poor mechanical properties, difficult to form uniform crystal nucleus, It is difficult to disperse uniformly, etc., to achieve the effect of low crystallinity, improved mechanical properties, and uniform distribution of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing an ultra-high molecular weight polyethylene fiber spinning dope, comprising:

[0054] Mixing the UHMWPE solution with the UHMWPE swelling solution at a weight ratio of 0.42 to 2.85 to obtain a spinning stock solution with an UHMWPE weight content of 10% to 15%;

[0055] The weight ratio of the UHMWPE in the UHMWPE swelling solution to the UHMWPE in the UHMWPE solution is 2.5-70.

[0056] The ultra-high molecular weight polyethylene solution refers to a solution obtained by dissolving ultra-high molecular weight polyethylene into a solvent well known to those skilled in the art.

[0057] According to the present invention, the weight content of ultra-high molecular weight polyethylene in the ultra-high molecular weight polyethylene swelling liquid is preferably 11% to 49%, more preferably 15% to 40%, and most preferably 20% to 35%. The weight content of the ultra-high molecular weight polyethylene in the ultra-h...

Embodiment 1

[0083] Prepare ultra-high molecular weight polyethylene colored fibers according to the following procedures:

[0084] Process 1. Prepare ultra-high molecular weight polyethylene colored swelling liquid;

[0085] Process 2, preparation of ultra-high molecular weight polyethylene solution;

[0086] Step 3, preparing ultra-high molecular weight polyethylene spinning colored stock solution;

[0087] Process 4, spinning.

[0088] Process 1 specifically includes the following steps:

[0089] step 11

[0090] Take 50kg of the first white oil and place it in the swelling kettle for stirring, and evenly spray 30kg of ultra-high molecular weight polyethylene powder into it while stirring;

[0091] Step 12

[0092] Get the 3rd part of white oil of 4kg, add the sodium dodecylbenzenesulfonate surfactant of 0.05kg antioxidant, 0.06kg then and carry out emulsification stirring emulsification and obtain the first emulsification solvent, wherein stirring speed is 3000rpm, emulsification ...

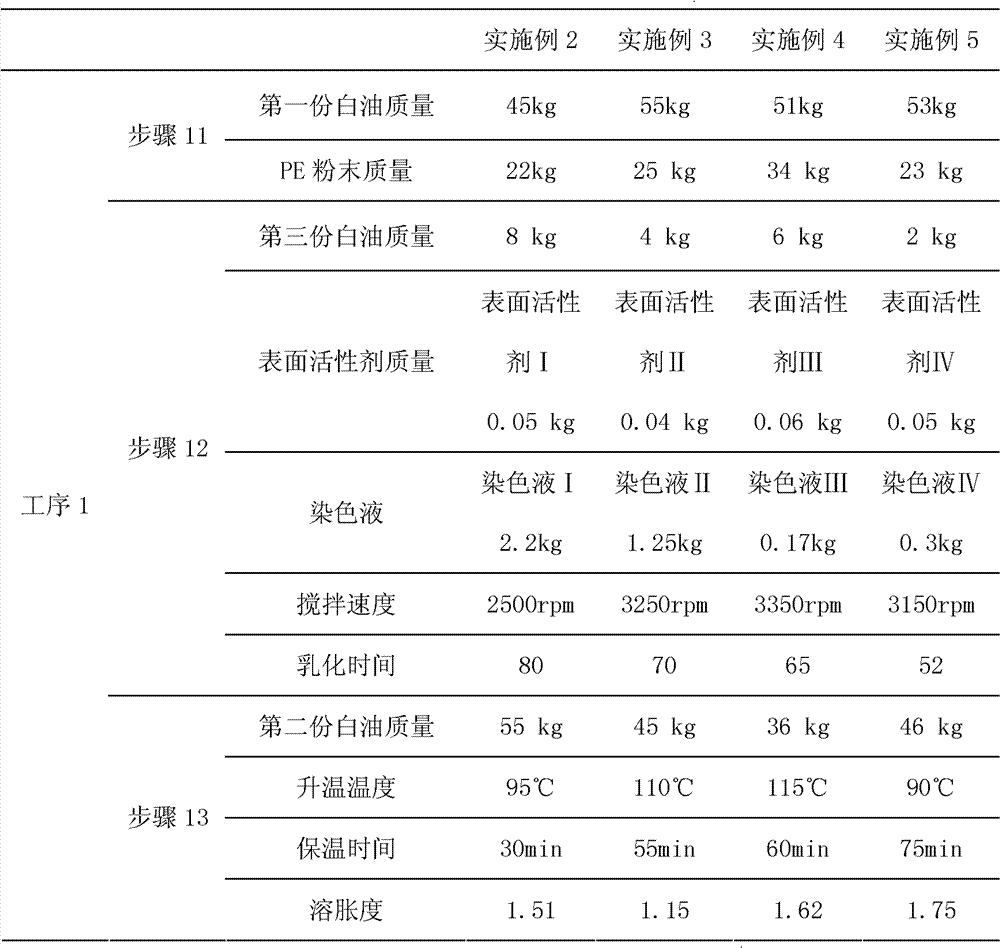

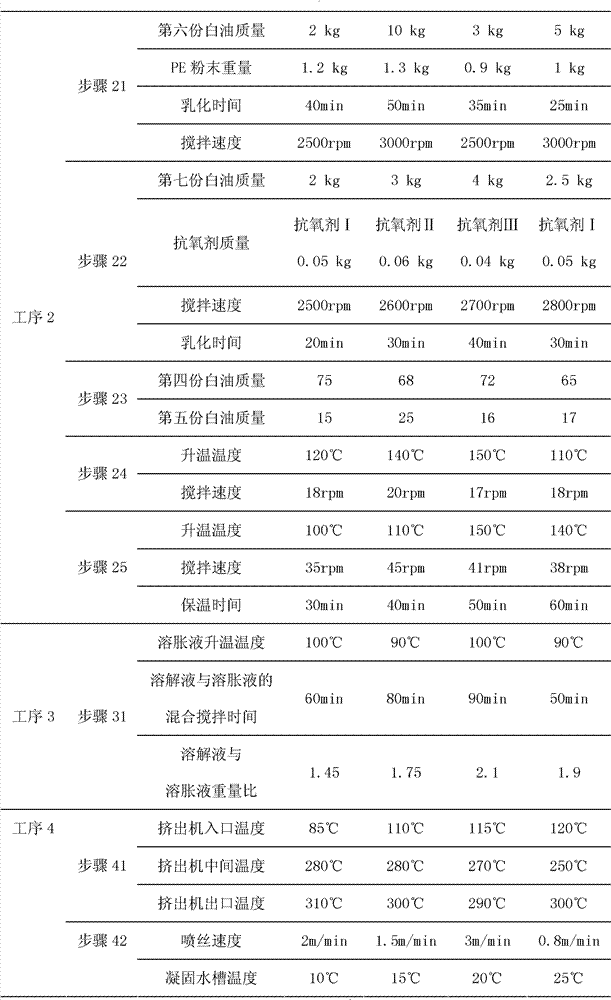

Embodiment 2- Embodiment 9

[0121] Please refer to Table 2 and Table 3 for the process parameters of the above eight implementations, and the parameters not listed in Table 2 and Table 3 are the same as those in Example 1.

[0122] The various indexes of the spinning dope and the results of the mechanical properties of the fibers are listed in Table 4 and Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com