Continuous production line device for microwave dry-distilling and cracking biomass

A production line and biomass technology, which is applied in the field of microwave dry distillation and cracking biomass continuous production line devices, can solve the problems of low charcoal yield, large thermal inertia, and waste of heat energy, etc., and achieve improved charcoal yield, high thermal efficiency, and quality assurance and the effect on yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

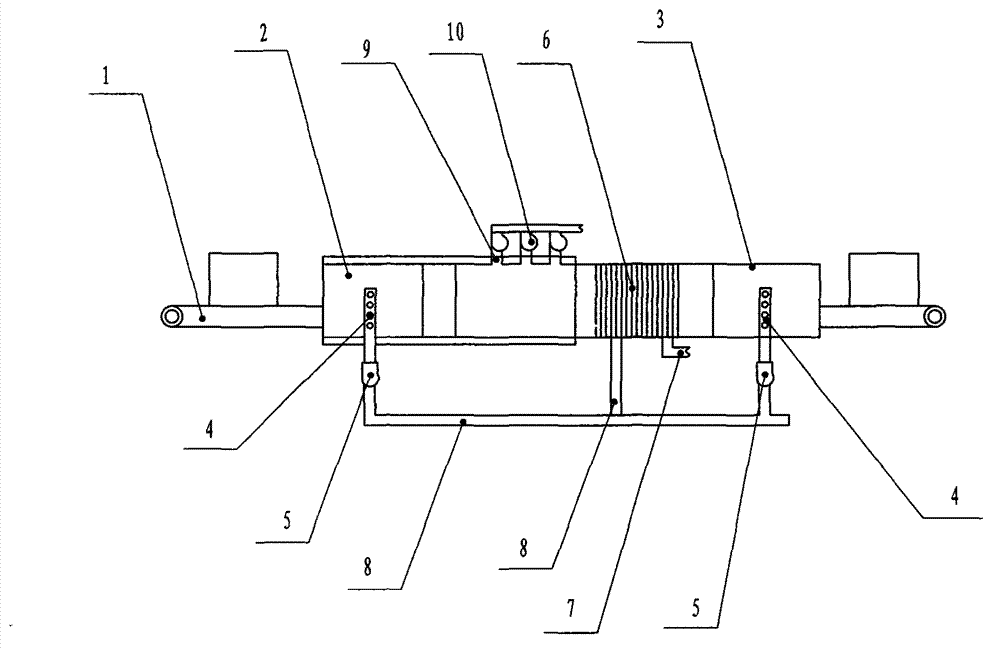

[0011] A continuous production line device for microwave dry distillation and pyrolysis of biomass, such as figure 1 As shown, it includes: a carbonization furnace shell, a transport conveyor belt 1, the transport conveyor belt is installed in the carbonization furnace shell, and the carbonization furnace shell is divided into a microwave dry distillation cracking chamber 2 and a cooling chamber 3; the microwave dry distillation cracking chamber 2 is divided into micro Positive pressure zone, preheating zone, medium temperature zone, micro positive pressure high temperature dry distillation zone; microwave wire is installed in the housing of microwave dry distillation cracking chamber 2; cooling chamber 3 is divided into cooling zone, atomization cooling zone and drying zone; preheating An air duct 4 is designed above the area and the drying area, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com