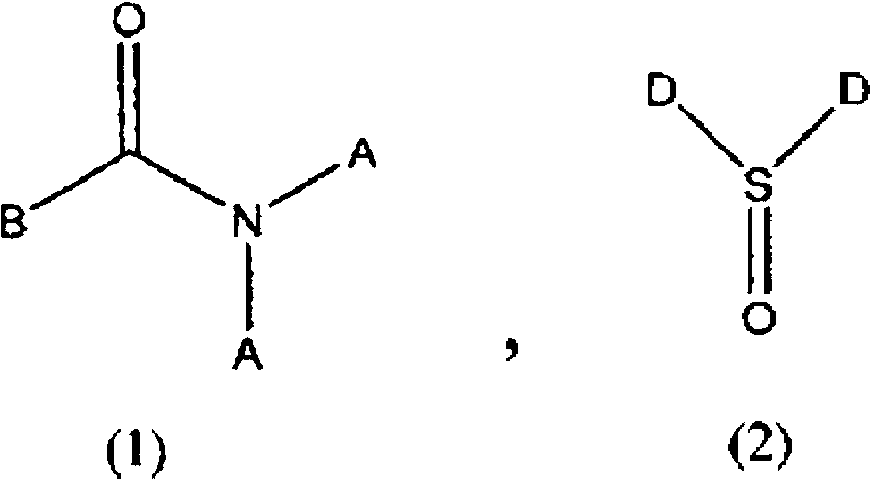

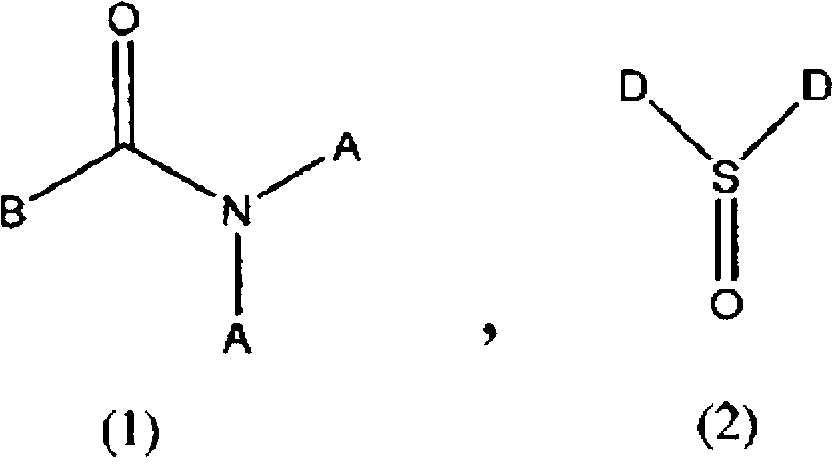

Method for producing difluoroacetic acid ester

A technology of difluoroacetate and manufacturing method, which is applied in the direction of carboxylic acid ester preparation, carboxylic acid halide preparation, chemical instruments and methods, etc., can solve the problems of increasing solubility and reducing recovery rate, and achieve the improvement of comprehensive yield, The effect of low environmental load and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The present invention will be described below using examples, but the embodiments of the present invention are not limited thereto. In the examples, ethyl difluoroacetate (CHF 2 COOEt), ethanol (EtOH), difluoroacetic acid (CHF 2 COOH) and other organic components are measured by FID gas chromatography (GC), and the content of inorganic acids such as hydrogen fluoride is measured by ion chromatography (IC).

Synthetic example 1

[0071] Aluminum phosphate manufactured by Aldrich was pelletized into pellets of 5 mmφ×5 mmL, and fired at 700° C. for 5 hours in a nitrogen stream to prepare an aluminum phosphate catalyst. 2200 cc of this was filled in a large gas phase reaction tube (made of stainless steel, inner diameter 43 mmφ×1800 mmL) equipped with a vaporizer. While flowing nitrogen gas at a rate of 1000 cc / min, the reaction tube was heated by an external electric furnace. After the temperature of the catalyst reached 50° C., hydrogen fluoride (HF) was introduced at a maximum rate of 6 g / min through the vaporizer while monitoring so as not to generate sudden heat generation. In the state of circulating HF, slowly raise the temperature to 300°C, slowly increase the HF supply rate to 12g / min, and keep it at 300°C for 72 hours, after that, lower the set temperature of the heater, and the internal temperature reaches 250°C , stop the flow of HF, increase the nitrogen flow rate to 2000cc / min, keep it for ...

Synthetic example 2

[0073] Aluminum phosphate manufactured by Aldrich was pelletized into pellets of 5 mmφ×5 mmL, and fired at 700° C. for 5 hours in a nitrogen stream to prepare an aluminum phosphate catalyst. 200 cc of this was filled in a small gas phase reaction tube (made of stainless steel, inner diameter 37 mmφ×500 mmL) equipped with a vaporizer. While flowing nitrogen gas at a rate of 100 cc / min, the reaction tube was heated by an external electric furnace. After the temperature of the catalyst reached 50° C., hydrogen fluoride (HF) was introduced through the vaporizer at a maximum rate of 0.6 g / min while monitoring so as not to generate sudden heat generation. In the state of circulating HF, slowly raise the temperature to 300°C, slowly increase the HF supply rate to 1.2g / min, and keep it at 300°C for 72 hours, after that, lower the set temperature of the heater, and the internal temperature reaches 250 At ℃, stop the flow of HF, increase the nitrogen flow to 200cc / min, keep it for 8 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com