Method for forming holes in substrate of nitride device by mixing type etching

A nitride and hybrid technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as poor selectivity and difficult laser operation, and achieve the effect of improving yield and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

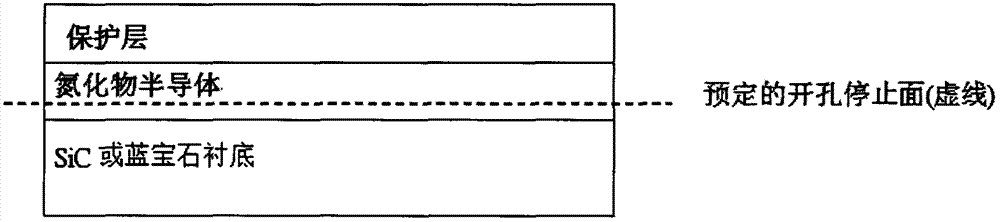

[0031] Example 1: Hole stopped in nitride semiconductor on substrate

[0032] Such as Figure 1 to Figure 4 As shown, the process is as follows:

[0033] (1) if figure 1 As shown, the other side of the opening is protected.

[0034] On the backside of the processed surface of the semiconductor wafer, a water-soluble resist was evenly applied to the entire surface with a spin coater, and dried to form a protective film with a thickness of 2 μm.

[0035]When a laser processing machine is irradiated, the dirt scatters violently and adheres to the front and back of the semiconductor wafer during processing. As a result of EDX (Energy Dispersive X-ray, X-ray energy spectrum quantitative analysis) analysis of the dirt with an electron microscope (FE-SEM), it is Al, O, C, Cl, Si with the composition of compound semiconductors and substrates Equivalent to at least one elemental composition. Therefore, the reverse side of the processed surface is covered with a protective layer be...

Embodiment 2

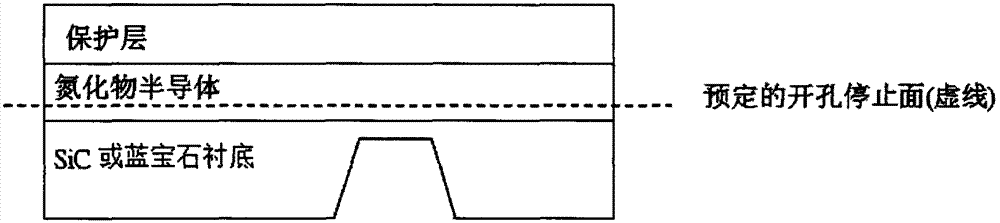

[0050] Embodiment 2: as Figure 5 As shown, the difference between this embodiment and Embodiment 1 lies in that: the opening stops at the metal layer on the substrate.

Embodiment 3

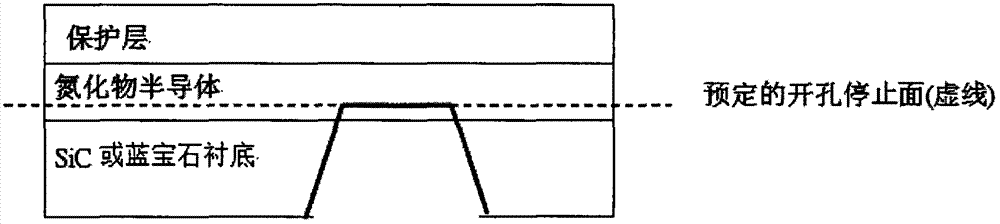

[0051] Embodiment 3: as Figure 6 As shown, the difference between this embodiment and Embodiment 1 lies in that the opening penetrates the nitride semiconductor on the surface of the substrate and stops on the metal layer on the nitride semiconductor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com