Method for manufacturing p-type and n-type semiconductor light extraction vertical conduction LED (light-emitting diode)

A technology of light-emitting diodes and n-type semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that the electrodes cannot get the best light output, the sapphire substrate is not easy to drill holes, and the yield rate has a huge impact, so as to increase The effect of light output and luminous efficiency, improving yield rate and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: p-type semiconductor emits light

[0049] The manufacturing method of the p-type semiconductor light-emitting vertical conduction light-emitting diode:

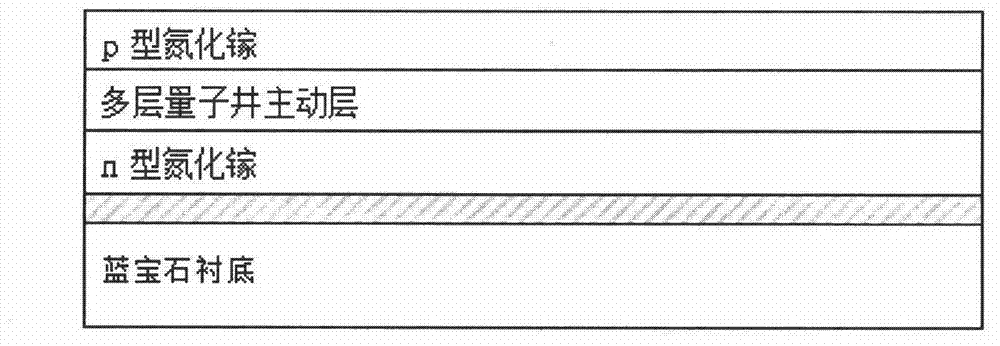

[0050] (1) if figure 1As shown, a sapphire substrate is provided, and a light-emitting structure of a light-emitting diode is epitaxially grown on the front surface of the substrate. The light-emitting structure includes a GaN buffer layer and a GaN light-emitting diode epitaxial layer formed in sequence. The GaN light-emitting diode epitaxial layer includes an n-type GaN layer, a multi-layer quantum well active layer (multi-quantum well active layer, MQW active layer, that is, a light-emitting layer) and a p-type nitride layer arranged in sequence. Gallium layer;

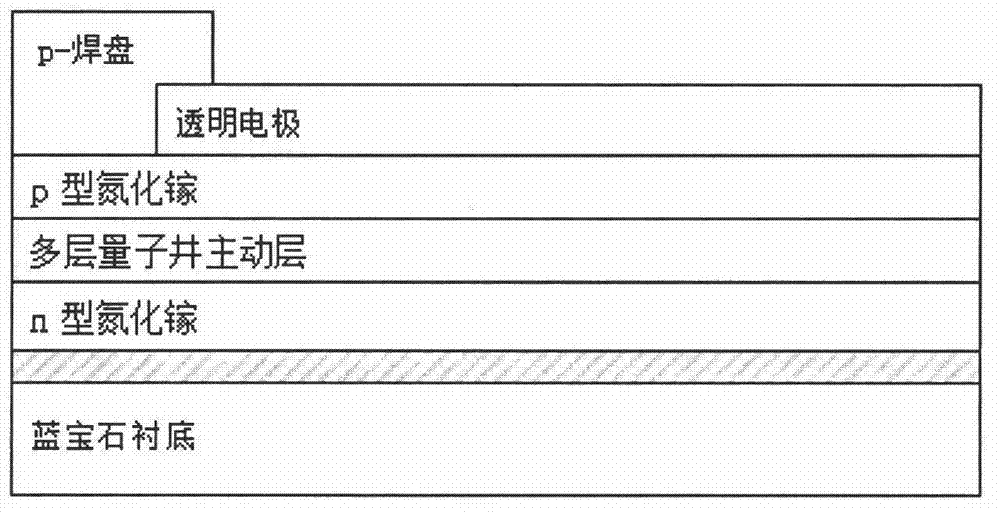

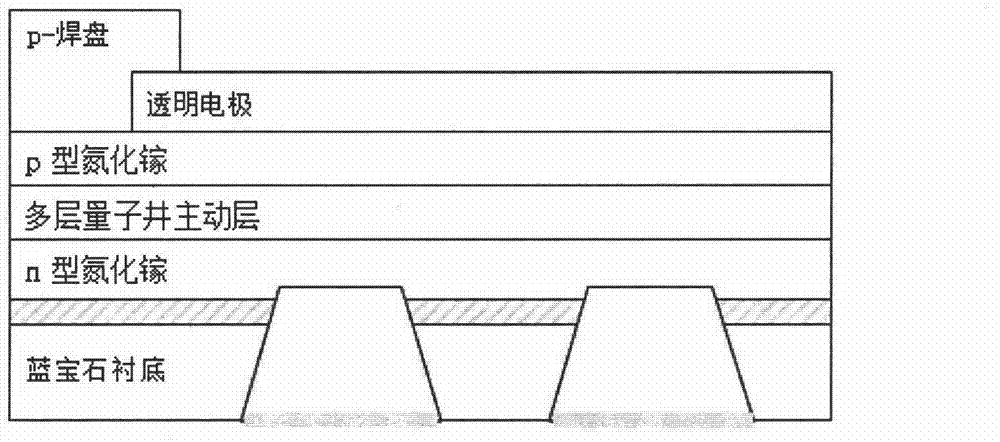

[0051] (2) if figure 2 As shown, a p-electrode structure is formed on the p-type gallium nitride layer. The p-electrode structure includes a transparent electrode and a p-bonding pad arranged in sequence, and can be connected to an external c...

Embodiment 2

[0071] Example 2: n-type semiconductor light output

[0072] Such as Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the p-electrode in this embodiment is exactly the structure of the n-electrode in Embodiment 1, and the structure of the n-electrode in this embodiment is exactly the structure of the n-electrode in Embodiment 1. In the structure of the p-electrode, the pad in this embodiment is not a p-pad, but an n-pad. Figure 13 yes Figure 12The bottom view of , showing the light-emitting surface (reverse surface, n-electrode side) of the n-type semiconductor light-emitting vertical conduction light-emitting diode. Figure 14 yes Figure 12 The top view of , shows the front side (p-electrode side) of the n-type semiconductor light-emitting vertical conduction light-emitting diode, and the dotted line is the pattern of the n-pad and the sapphire hole on the back side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com