A hole opening device for a guide sleeve

A technology for guide sleeves and positioning devices, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems affecting the performance of guide sleeves, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

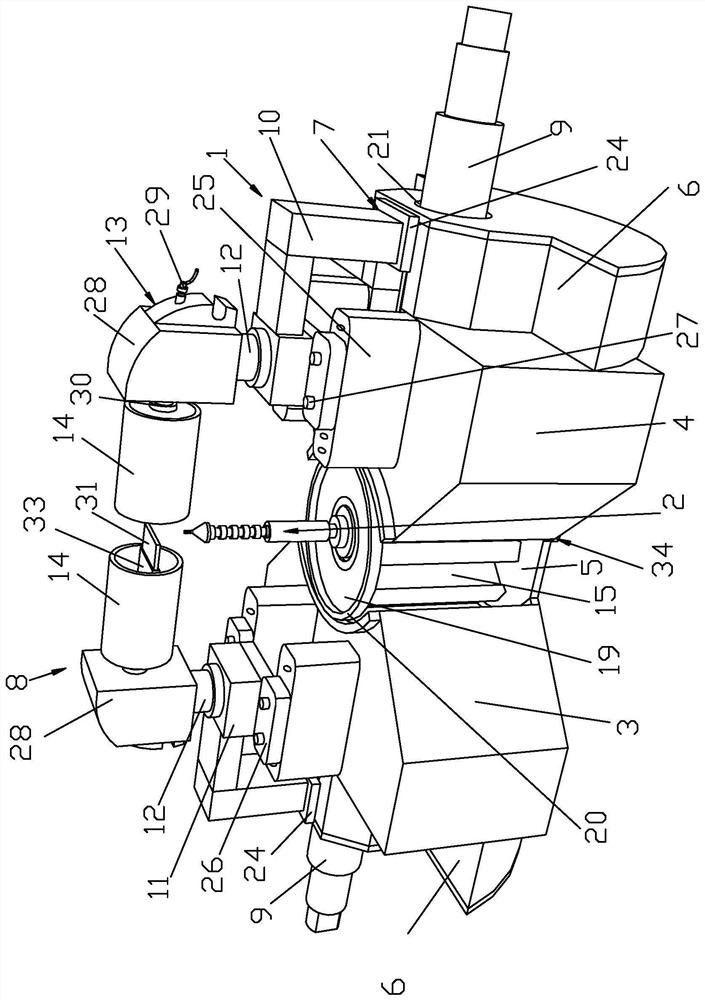

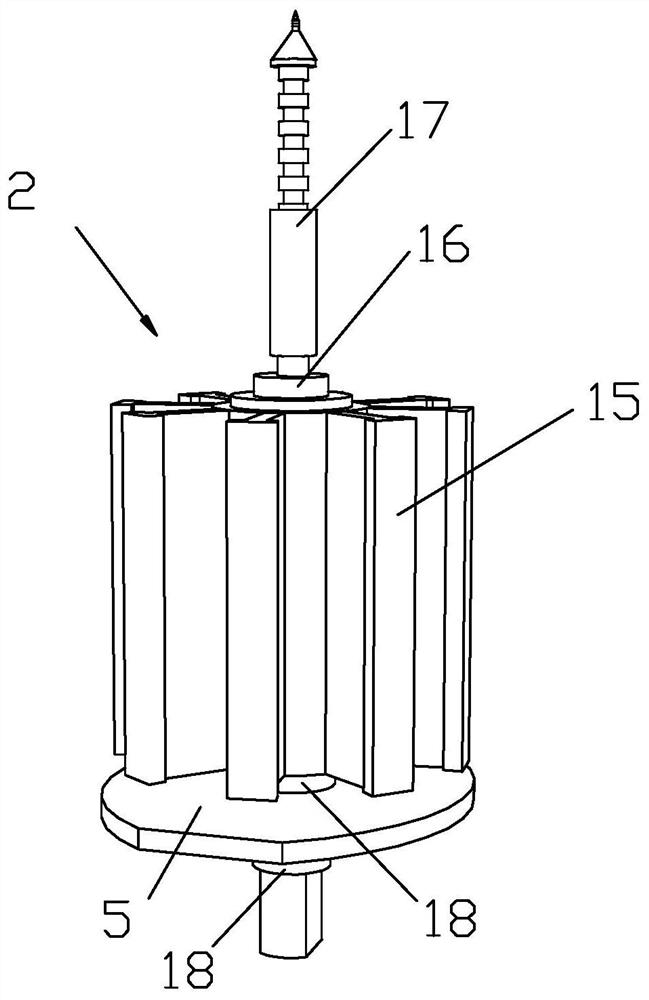

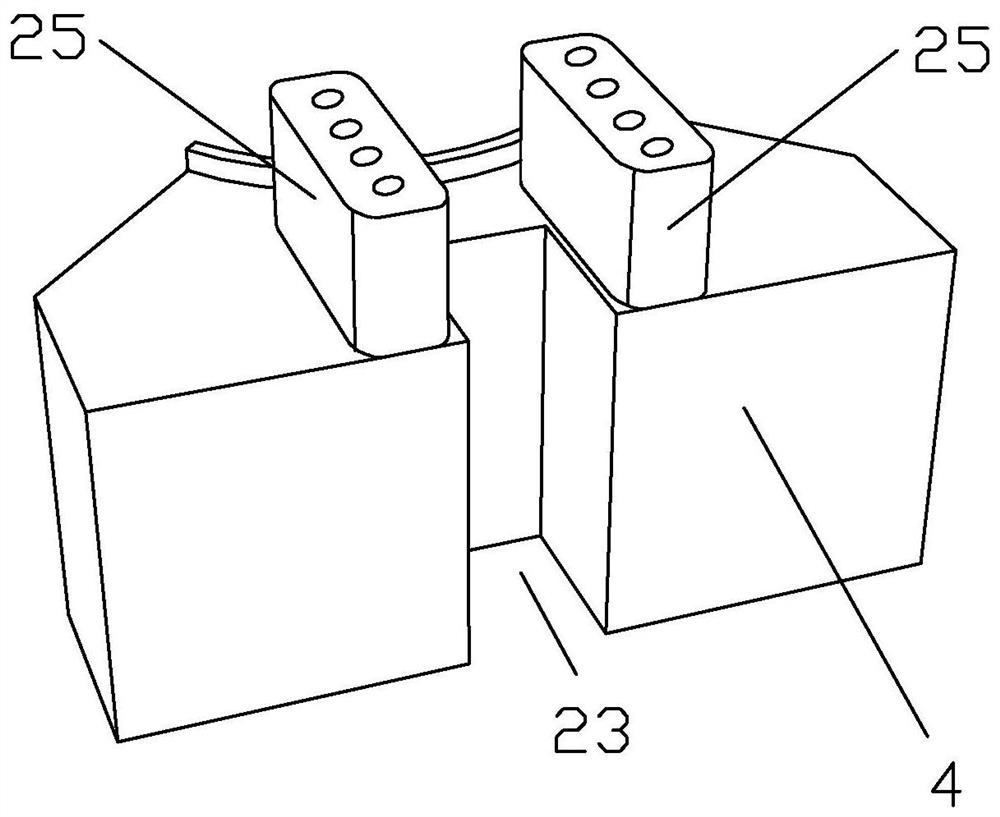

[0023] Such as Figure 1 to Figure 5As shown, it is a drilling device for a guide sleeve according to the present invention, which includes a support assembly 34, a positioning device 1 and a drill assembly 2. The support assembly 34 includes a left operating platform 3, a right operating platform 4 and a mounting plate 5, and the left operating An installation groove is formed between the table 3 and the right operation table 4, the installation plate 5 is installed in the installation groove and fixedly connected with the left operation table 3 and the right operation table 4, the positioning device 1 includes a support plate 6, a width adjuster 7 and a height adjustment 8, the support plate 6 is fixedly installed on the outside of the left console 3 and the right console 4 respectively, the width adjuster 7 includes an adjustment rod 9, a connecting plate 10 and a support base 11, the adjustment rod 9 passes through the support plate 6, and the adjustment rod The top of 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com