Method for preparing lactide continuously

A technology of lactide and esterification catalyst, applied in the direction of organic chemistry, can solve the problems of no description, defects, investment and production costs, etc., and achieve the effect of high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

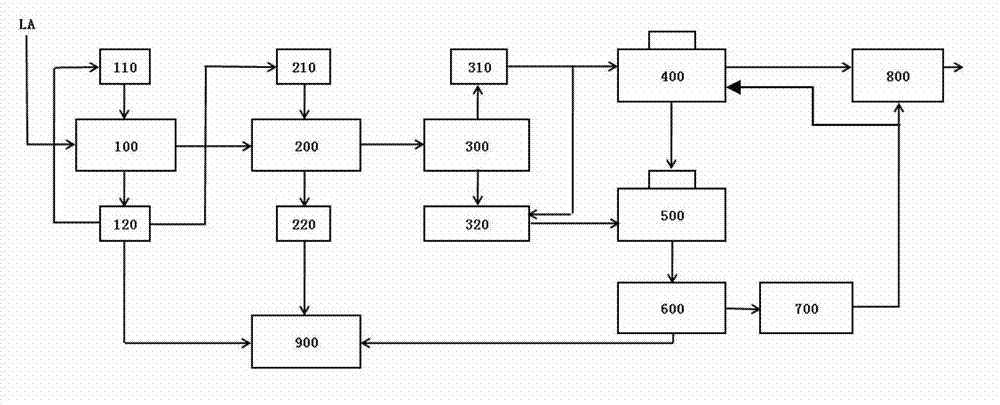

Method used

Image

Examples

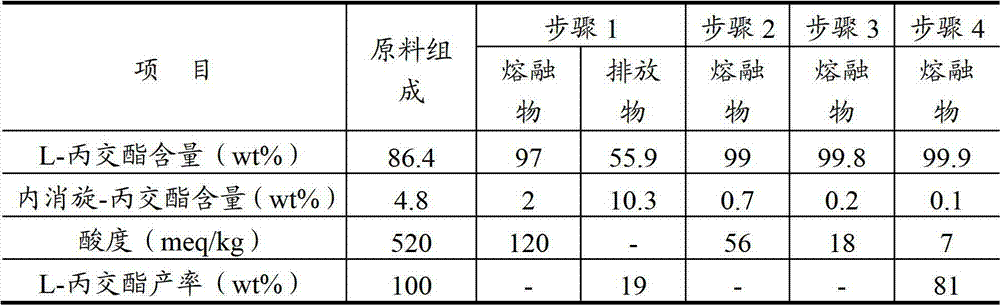

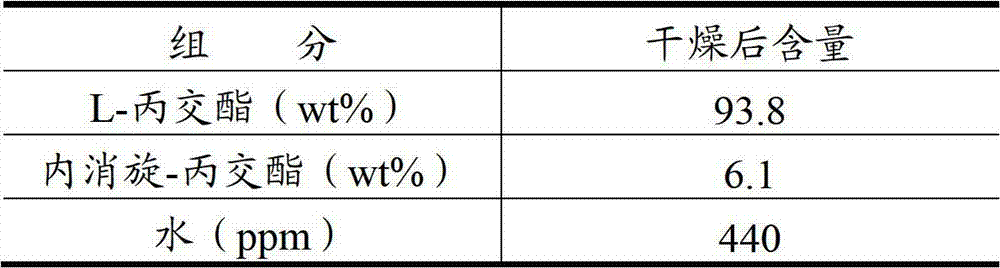

Embodiment 1

[0072] Step 1: In a 1000ml reactor A equipped with an electric stirring system, a condensation system, a constant temperature heating system, and a vacuum system. According to 600ml / min, continuously add lactic acid with a weight content of 90% (the weight content of L-isomer accounts for 97.6%), adjust the heating resistor to control the heating temperature at 100°C, and vacuumize to 400kpa. In order to prevent too much lactic acid from being carried over in the effluent, a reactor with a height of 900mm and a cross-sectional area of 0.36m is placed on the top of the reactor. 2 The packed ring condensation column. There is a temperature indicator on the top of the column to monitor the temperature change, and at the same time reduce the heating power as much as possible to prevent more lactic acid from being taken away. Keep this state for 1.5 hours. Through the communication with the reactor B, adjust the valve to automatically enter the reactor B through the liquid phase...

Embodiment 2

[0081] Step 1: In a 1000ml reactor A equipped with an electric stirring system, a condensation system, a constant temperature heating system, and a vacuum system. According to 600ml / min, continuously add lactic acid with a weight content of 90% (the weight content of L-isomer is 97.6%), adjust the heating resistance to control the heating temperature at 95°C, and vacuumize to 200Kpa. In order to prevent too much lactic acid from being carried over in the effluent, a reactor with a height of 900mm and a cross-sectional area of 0.36m is placed on the top of the reactor. 2 The packed ring condensation column. There is a temperature indicator on the top of the column to monitor the temperature change, and at the same time reduce the heating power as much as possible to prevent more lactic acid from being taken away. Keep this state for 1.5 hours. Through the communication with the reactor B, adjust the valve to automatically enter the reactor B through the liquid phase material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com