Auto front anti-collision beam made of carbon fiber/aramid fiber reinforced material

A technology for reinforcing composite materials and front anti-collision beams, which is applied in synthetic resin layered products, bumpers, layered products, etc. Vehicle safety, improving strength and toughness, overcoming brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

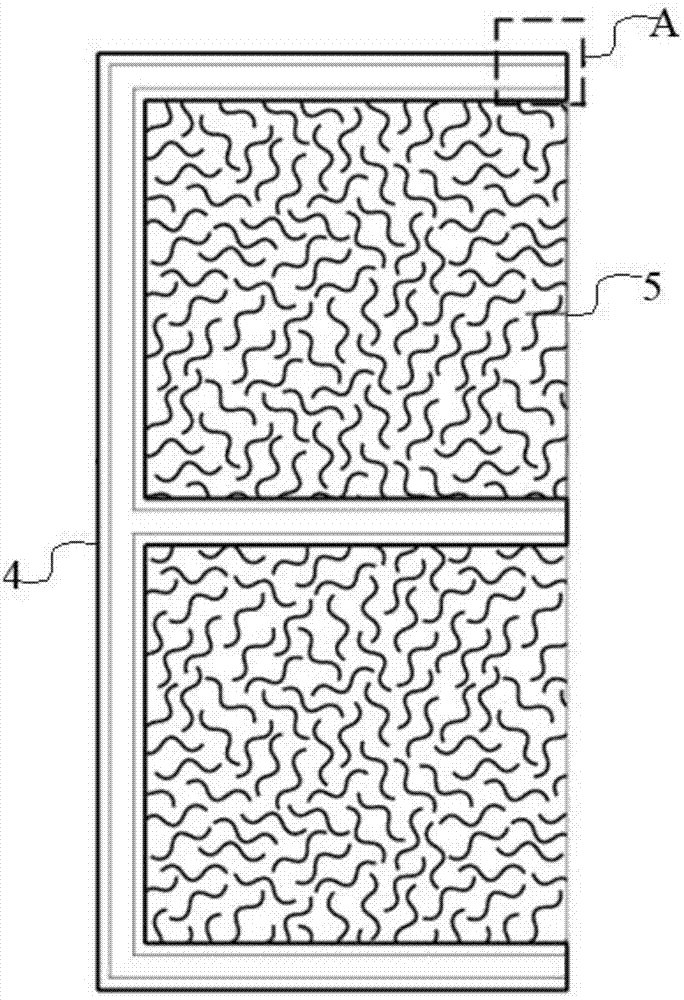

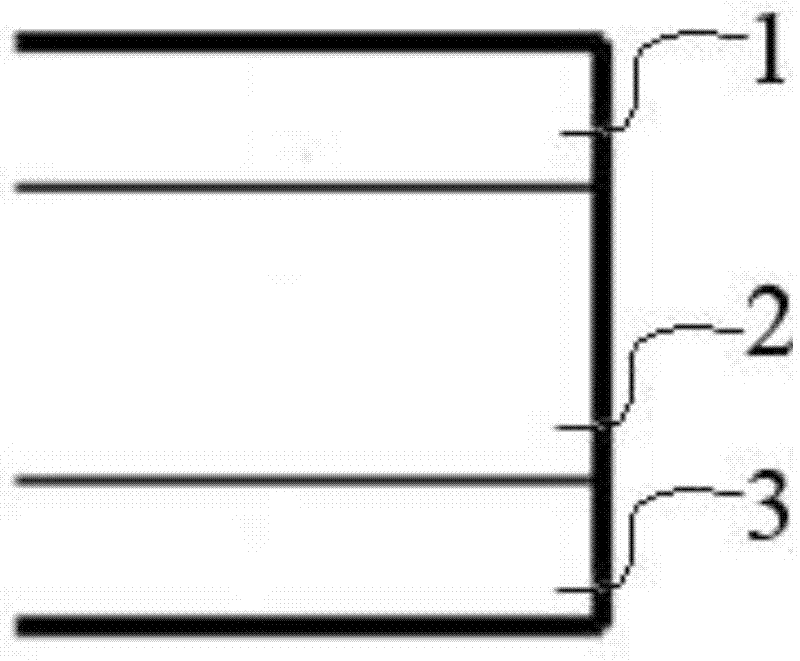

[0026] like figure 1 and figure 2 As shown, the automobile front crash beam prepared by carbon fiber / aramid fiber reinforced composite material of the present invention includes a basic frame 4 with two cavities 5, and the material of the basic frame 4 is a first restraint layer 1 containing aramid fibers. , a carbon fiber / aramid reinforced resin-based composite material composed of a second constraining layer 3 containing aramid fibers and an intermediate layer 2 containing carbon fibers located between the first constraining layer 1 and the second constraining layer 3; The cavity 5 is filled with rigid foam, and the rigid foam is adjacent to the second constraining layer 3 .

Embodiment 2

[0028] Using the prepreg layup-autoclave co-curing molding process, as the first constraining layer, a layer of aramid fiber cloth (Beijing Juneng, JNAFS-1670-170P plain weave cloth) was laid on two pieces of aramid fiber cloth that were on the same plane and On the PMI foam (Evonik Rohacell 51IG PMI) of 30mm×30mm×1200mm (length×width×thickness) arranged at parallel intervals along the length of the foam, according to figure 1 The structure shown is in turn covered with unidirectional carbon fiber epoxy resin prepreg (Guangwei USG12503) on the above aramid fiber cloth. 2s , and 1 layer of aramid fiber cloth (Beijing Juneng, JNAFS-1670-170P plain weave) as the second constraining layer. After heating and curing at 120°C for 2 hours and 160°C for 1 hour, a car front crash beam sample prepared by the carbon fiber / aramid reinforced composite material having the structure of Example 1 was obtained. Among them, the volume percentage composition of the carbon fiber / aramid reinforced...

Embodiment 3

[0031]The carbon fiber / aramid fiber reinforced composite material basic skeleton 4 with two cavities is prepared by the prepreg layup-autoclave co-curing molding process, and the PMI foam is filled in the cavity 5 through epoxy adhesive bonding. Including: as the first constraining layer, a layer of aramid fiber cloth (Beijing Juneng, JNAFS-1670-170P plain weave) is laid on the mold, and the mold is provided with the cavity size consistent with the cavity 5 on the basic skeleton 4 30mm×30mm×1200mm (length×width×thickness), according to figure 1 As shown in the structure, unidirectional carbon fiber epoxy resin prepreg (Guangwei USG12503) is layered on the above aramid fiber cloth in turn, and the layering method[0] 8 , and 1 layer of aramid fiber cloth (Beijing Juneng, JNAFS-1670-170P plain weave) as the second constraining layer. After 2 hours at 120°C and 1 hour at 160°C for heating and curing, the basic skeleton 4 of the carbon fiber / aramid reinforced composite material wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com