Preparation method of nitrogen-doped graphene

A nitrogen-doped graphene and graphite technology, applied in capacitors, structural parts, electrical components, etc., can solve problems such as complex process, high cost, and limitations on the application of nitrogen-doped graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

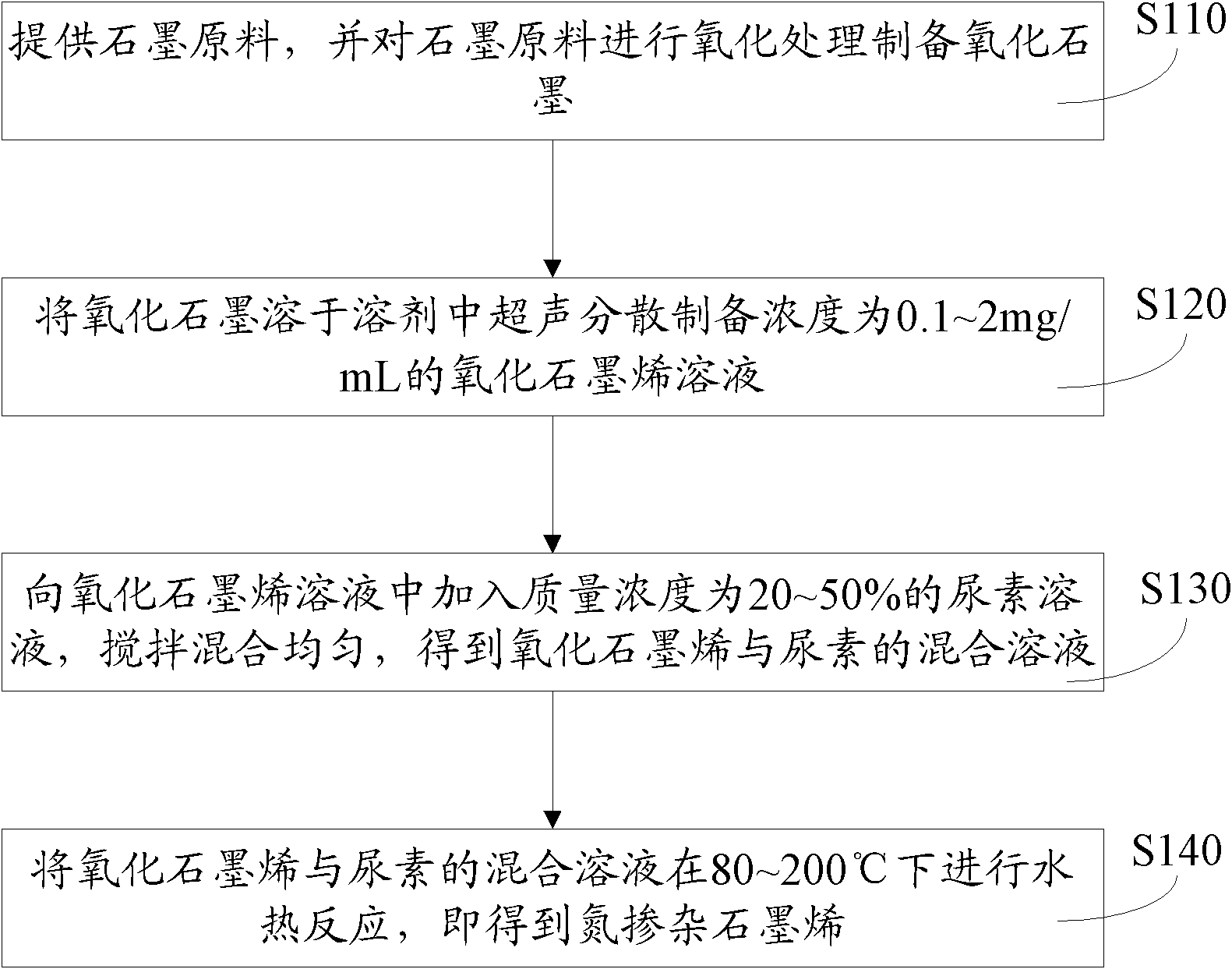

[0021] Such as figure 1 Shown, the preparation method of the nitrogen-doped graphene of one embodiment, comprises the steps:

[0022] Step S110: Oxidize the graphite raw material to prepare graphite oxide.

[0023] The above-mentioned graphite raw materials can be various forms of graphite powder, such as flake graphite, crystalline graphite and the like. In this embodiment, natural flake graphite with a purity of not less than 99.5% is preferred.

[0024] Among them, the following method can be used to prepare graphite oxide by oxidizing graphite raw materials: adding graphite raw materials, potassium persulfate and phosphorus pentoxide to concentrated sulfuric acid at 80°C, stirring evenly, cooling for more than 6 hours, suction filtration, and washing to Neutral, dry, get a mixed sample;

[0025] Add the mixed sample to concentrated sulfuric acid at 0°C, then add potassium permanganate, keep the temperature of the system below 20°C, then keep it in an oil bath at 35°C fo...

Embodiment 1

[0038] Graphite raw material→graphite oxide→graphene oxide solution→graphene oxide and urea mixed solution→nitrogen-doped graphene

[0039] (1) Graphite raw material: 50 meshes of natural flake graphite with a purity of 99.5%.

[0040] (2) Graphite oxide: Add 20g of graphite raw material, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6 hours, filter with suction, wash until neutral, and dry to obtain a mixed sample ;

[0041] Add the dried mixed sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the system below 20°C, then keep it in an oil bath at 35°C for 2 hours, then slowly add 920mL Deionized water;

[0042] After 15 minutes, add 2.8L of deionized water to the system until the color of the mixture turns bright yellow, filter while hot, then wash with 5L of 10% hydrochloric acid, filter with suction, and dry in vacuum a...

Embodiment 2

[0051] Step (1) and step (2) are the same as embodiment 1.

[0052] (3) Graphene oxide solution: Add the graphite oxide prepared in step (2) into water and ultrasonically disperse for 1 hour to form a graphene oxide solution with a concentration of 0.1 mg / mL uniformly dispersed in a monolithic layer.

[0053] (4) graphene oxide and urea mixed solution: adding mass fraction in the graphene oxide solution of step (3) is 20% urea solution, the volume ratio of graphene oxide solution and urea solution is 10: 1, stirs 10 minutes , so that the two are evenly mixed to obtain a mixed solution of graphene oxide and urea.

[0054] (5) Nitrogen-doped graphene: put the mixed solution obtained in step (4) into a hydrothermal kettle, and perform a hydrothermal reaction at 80° C. to obtain nitrogen-doped graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com