Electric brake

A technology of electric brakes and brake discs, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of large volume, cumbersome installation of hydraulic oil pipes, and easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

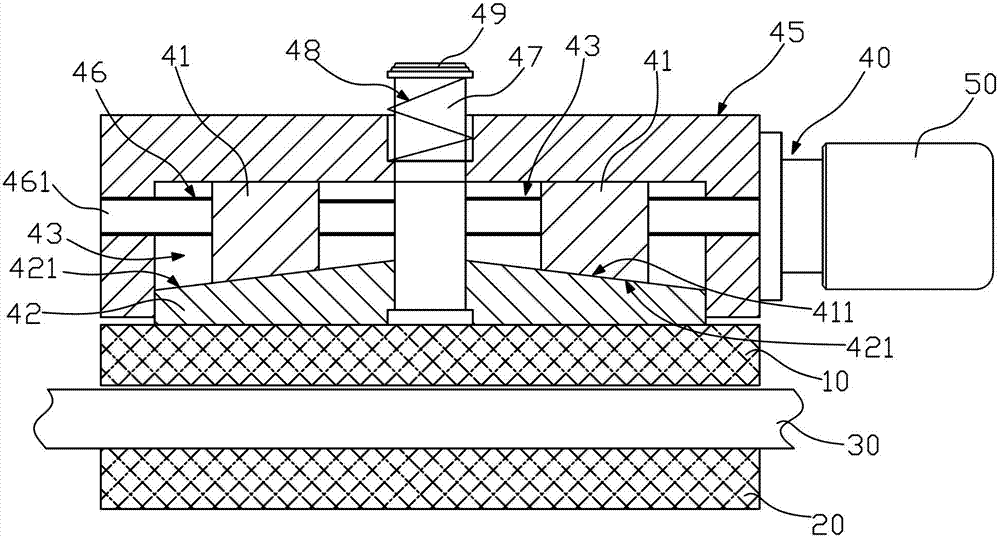

[0008] Such as figure 1 , an electric brake, including a dynamic friction plate 10 and a static friction plate 20, the dynamic and static friction plates 10, 20 are arranged on both sides of the brake disc 30, the dynamic friction plate 10 is fixed on the actuator 40, the actuator 40 is connected to the motor 50 , and the actuator 40 drives the moving friction plate 10 away from or close to the brake disc 30 . The dynamic friction plate 10 is attached to the brake disc 30 to achieve braking. When the dynamic friction plate 10 is far away from the brake disc 30, the brake is released. The electric motor 50 is used to provide power without complicated hydraulic systems, which can simplify the structure, reduce the volume of the brake, and avoid It eliminates a series of problems such as leakage caused by hydraulic drive, and is suitable for vehicle installation.

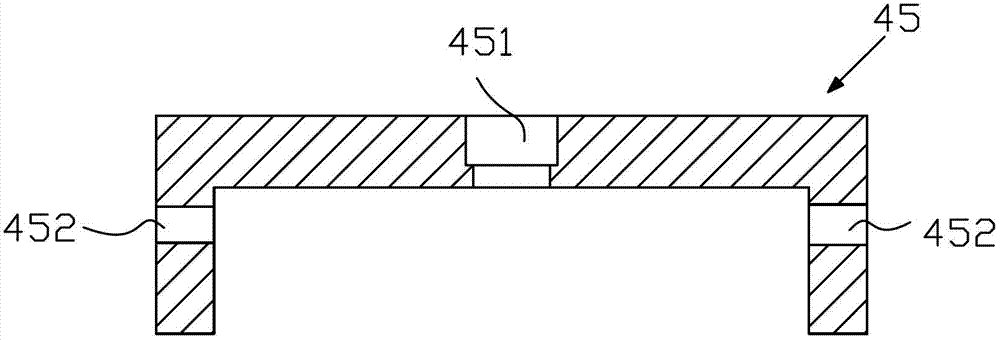

[0009] Such as figure 1 , the actuator 40 includes a housing 45 and a moving block 42 located on the side of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com