Process method for embedding cementation of Al-Si-Y on TiAl on alloy surface

A process method and co-infiltration technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc. The preparation technology and its application are still blank, etc., to achieve the effects of good high temperature oxidation resistance, good coating adhesion, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

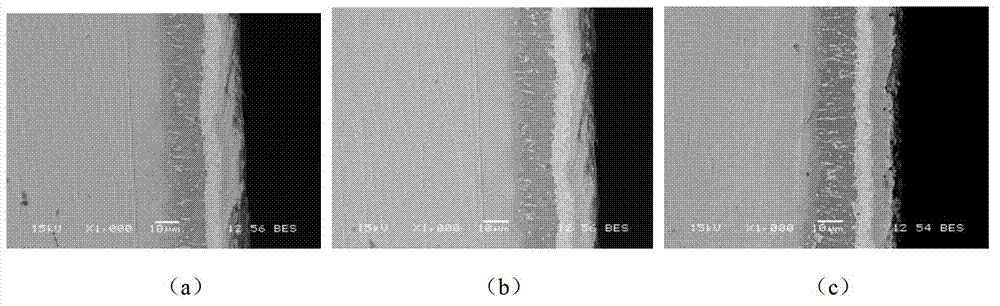

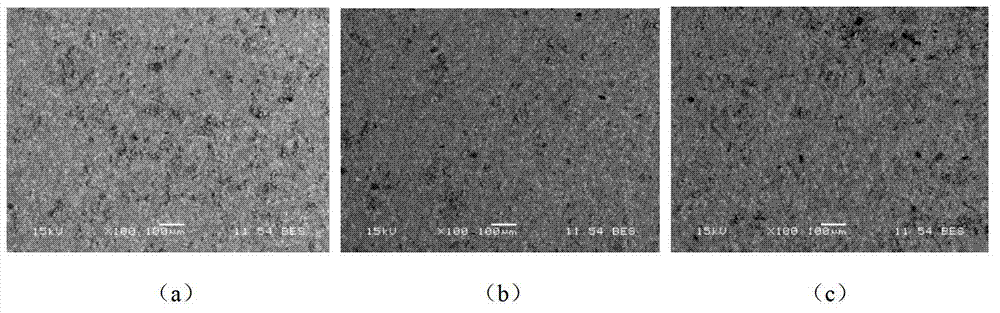

Embodiment 1

[0037] ① Prepare the sample: the sample is polished by 400# sandpaper, ultrasonically cleaned, and dried; ② Prepare the penetrating agent: accurately weigh the penetrating agent according to the amount, and the proportion of the penetrating agent is: 5% silicon (≤100 mesh) , 10% aluminum (≤100 mesh), 1% hexahydrate and aluminum chloride are analytically pure, 5% diyttrium trioxide (≤100 mesh), and the rest is aluminum oxide (≤200 mesh); The prepared penetrating agent was ground in a ball mill to make it fully mixed; ④Drying: Put the milled penetrating agent in an oven at 100°C for 1 hour to keep warm for drying; Put the sample into the crucible, and embed the sample in the infiltration agent. The distance between adjacent parallel samples is not less than 8mm. ⑥Seal: Cover the crucible with the sample and seal it with silica sol and aluminum oxide. Place in a high-temperature resistance furnace; ⑦Embedding infiltration: heat up to 1050°C for 1h, keep warm at 1050°C for 3h, and...

Embodiment 2

[0039] ① Prepare the sample: the sample is polished by 400# sandpaper, ultrasonically cleaned, and dried; ② Prepare the penetrating agent: accurately weigh the penetrating agent according to the amount, and the proportion of the penetrating agent is: 10% silicon (≤100 mesh) , 2% aluminum (≤100 mesh), 10% hexahydrate and aluminum chloride are analytically pure, 0.5% diyttrium trioxide (≤100 mesh), and the rest is aluminum oxide (≤200 mesh); The prepared penetrating agent was ground in a ball mill to make it fully mixed; ④Drying: Put the milled penetrating agent in an oven at 100°C for 1 hour to keep warm for drying; Put the sample into the crucible, and embed the sample in the infiltration agent. The distance between adjacent parallel samples is not less than 8mm. ⑥Seal: Cover the crucible with the sample and seal it with silica sol and aluminum oxide. Place in a high-temperature resistance furnace; ⑦Embedding: heat up to 1050°C for 1 hour, keep warm at 1050°C for 1 hour, and t...

Embodiment 3

[0041] ① Prepare the sample: the sample is polished by 400# sandpaper, ultrasonically cleaned, and dried; ② Prepare the penetrating agent: accurately weigh the penetrating agent according to the amount, and the proportion of the penetrating agent is: 8% silicon (≤100 mesh) , 5% aluminum (≤100 mesh), 5% hexahydrate and aluminum chloride are analytically pure, 3% diyttrium trioxide (≤100 mesh), and the rest is aluminum oxide (≤200 mesh); The prepared penetrating agent was ground in a ball mill to make it fully mixed; ④Drying: Put the milled penetrating agent in an oven at 100°C for 1 hour to keep warm for drying; Put the sample into the crucible, and embed the sample in the infiltrant. The distance between adjacent parallel samples is not less than 8mm. ⑥Seal: Cover the crucible with the sample and seal it with silica sol and aluminum oxide. Place in a high-temperature resistance furnace; ⑦Embedding infiltration: heat up to 1050°C for 1h, keep warm at 1050°C for 2h, then air coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com