Method for separating useful components from bayer process red mud

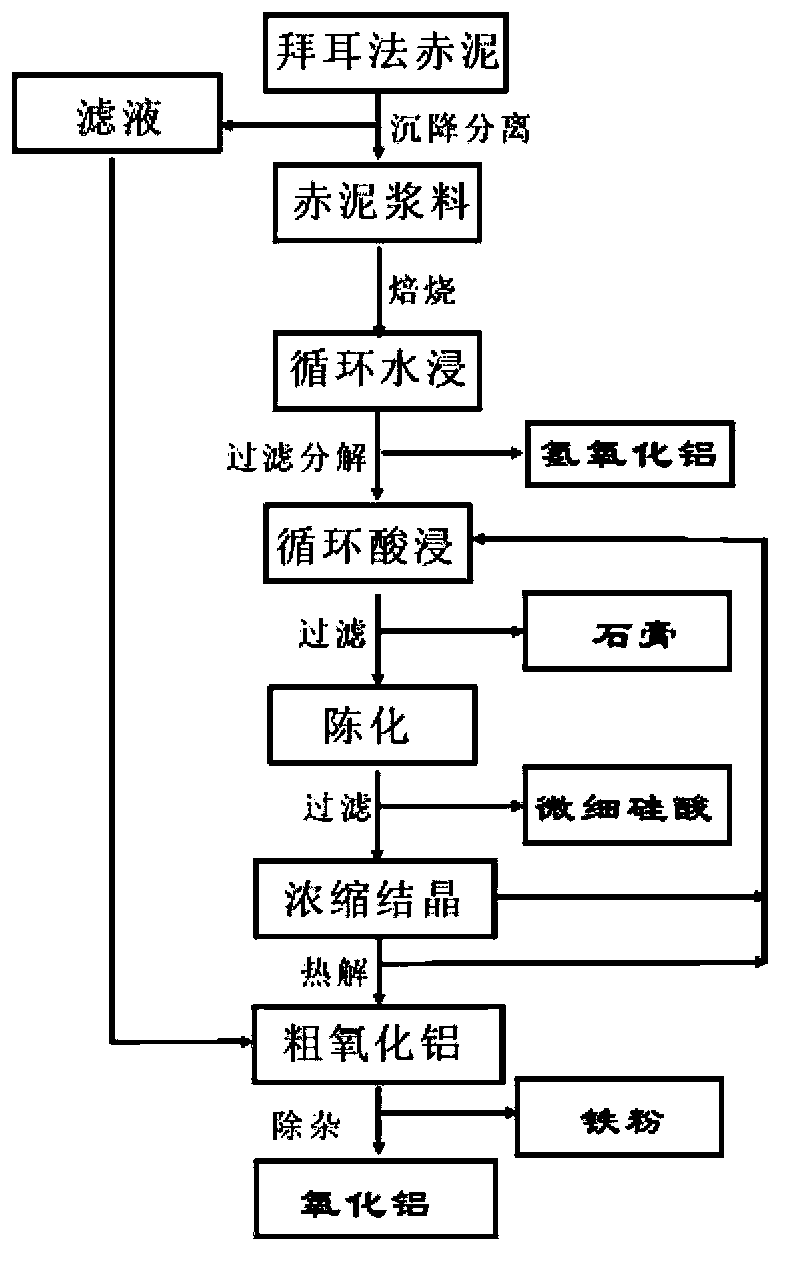

A Bayer process red mud, a useful technology, applied in the field of comprehensive utilization of red mud, can solve the problems of unreachable industrial production, increased slag viscosity, high iron and alkali content, etc., and achieve the effect of simple process, easy industrialization, and realization of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In the step (1): the water content of the red mud slurry is 36%.

[0049] In the step (2): roasting at 800° C. for 30 minutes to obtain roasted clinker.

[0050] In the step (3): water is added to the calcined clinker obtained in the step (2) at a solid-to-liquid ratio of 1:6, and leached at a temperature of 60°C for 10 minutes; and filtered after leaching to obtain The secondary filtrate and the primary filter residue; the obtained secondary filtrate is recycled for leaching the roasted clinker obtained in step (2).

[0051] In the step (4): add 4mol / L industrial sulfuric acid to the first filter residue obtained in step (3), and make the solid-liquid mass ratio 1:4; filter to obtain the second filter residue and the third filtrate; the third filtrate Contains silicon, aluminum and iron; the second filter residue is washed to obtain calcium sulfate product.

[0052] In the step (5): the three filtrates obtained in the step (4) are kept at a temperature of 60° C. for ...

Embodiment 2

[0057] In the step (1): the water content of the red mud slurry is 46%.

[0058] In the step (2): roasting at a temperature of 990° C. for 60 minutes to obtain roasted clinker.

[0059] In the step (3): water is added to the calcined clinker obtained in the step (2) at a solid-to-liquid ratio of 1:50, and leached for 30 minutes at a temperature of 80° C.; and filtered after leaching to obtain The secondary filtrate and the primary filter residue; the obtained secondary filtrate is recycled for leaching the roasted clinker obtained in step (2).

[0060] In the step (4): add 10mol / L industrial sulfuric acid to the first filter residue obtained in step (3), and make the solid-liquid mass ratio 1:20; filter to obtain the second filter residue and the third filtrate; the third filtrate Contains silicon, aluminum and iron; the second filter residue is washed to obtain calcium sulfate product.

[0061] In the step (5): filter the three filtrates obtained in the step (4) at a temper...

Embodiment 3

[0066] In the step (1): the water content of the red mud slurry is 40%.

[0067] In the step (2): roasting at 900° C. for 40 minutes to obtain roasted clinker.

[0068] In the step (3): add water to the roasted clinker obtained in the step (2) according to the ratio of solid to liquid ratio of 1:20, and leaching at a temperature of 70°C for 20 minutes; and filtering after leaching to obtain The secondary filtrate and the primary filter residue; the obtained secondary filtrate is recycled for leaching the roasted clinker obtained in step (2).

[0069] In the step (4): add 7mol / L industrial sulfuric acid to the first filter residue obtained in step (3), and make the solid-liquid mass ratio 1:10; filter to obtain the second filter residue and the third filtrate; the third filtrate Contains silicon, aluminum and iron; the second filter residue is washed to obtain calcium sulfate product.

[0070] In the step (5): the three filtrates obtained in the step (4) are kept at a tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com