Optical transition layer material, optical substrate/packaging layer, OLED (Organic Light Emitting Diode) and manufacturing methods thereof

A technology of transition layer and encapsulation layer, which is applied in the fields of optical substrate (encapsulation layer), OLED and their respective manufacturing methods, and optical transition layer materials, and can solve problems such as shortening the service life of devices, increasing material costs, and increasing the temperature of organic functional layers. Achieve the effect of improving light extraction efficiency, improving light extraction efficiency, and reducing total reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

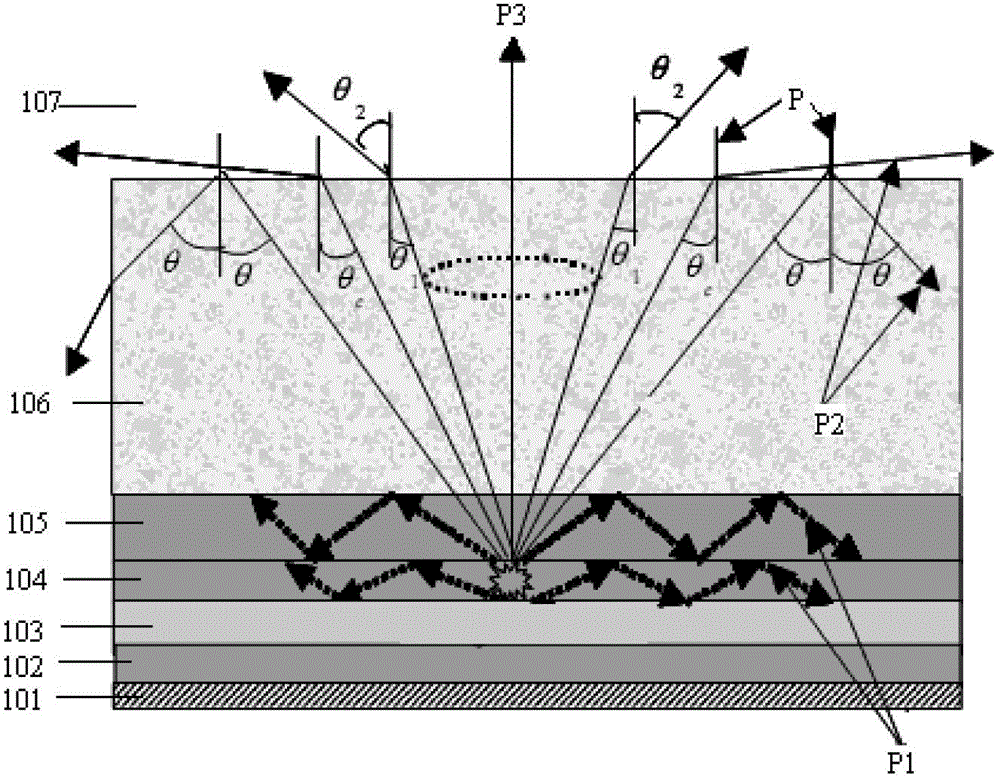

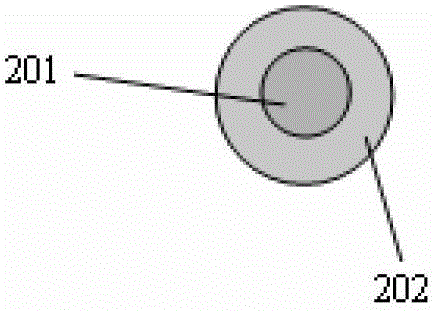

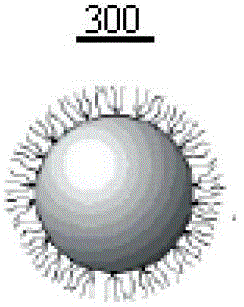

[0051] The basic concept of the present invention is: in order to improve the light extraction efficiency of OLED, prepare a special optical transition layer material, by preparing an optical transition layer on the surface of the substrate (encapsulation layer) of glass and other materials, the optical transition layer is composed of organic material main body layer and Composed of inorganic nanoparticles, it can reduce the total reflection loss of light and greatly improve the light extraction efficiency.

[0052] Key of the present invention is:

[0053] (1) The selection of nanoparticles requires high visible light transmittance, low light absorbance, stable physical and chemical properties (light, heat, water vapor, oxygen), and no reaction with organic carriers, generally wide bandgap semiconductors and insulating oxides , such as SiO 2 , MgO, MgF 2 、TiO 2 , ZnO, Al 2 o 3 , ZrO 2 Wait;

[0054] (2) The selection of organic materials requires high visible light tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com