Wet surface processing technique used for manufacturing high efficiency crystalline silicon solar cells

A crystalline silicon solar cell, wet processing technology, applied in the direction of post-processing, post-processing details, sustainable manufacturing/processing, etc., can solve the problems of increasing battery cost, difficult fragmentation rate, etc., to reduce process cost and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

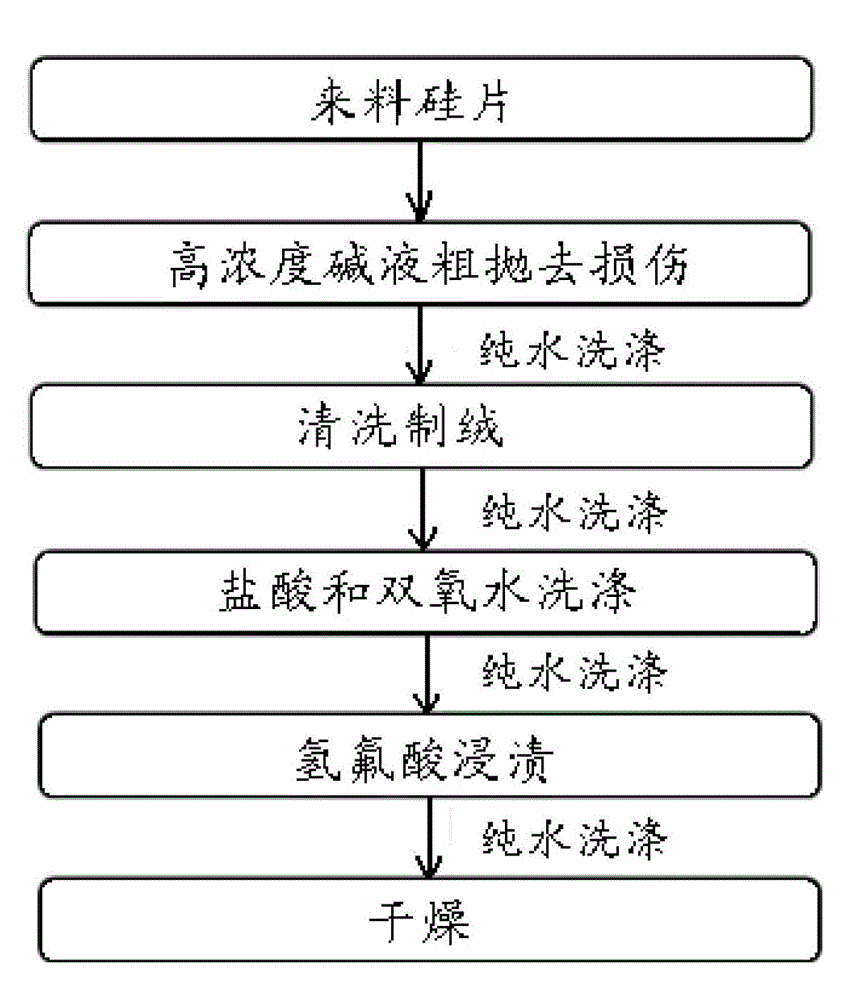

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

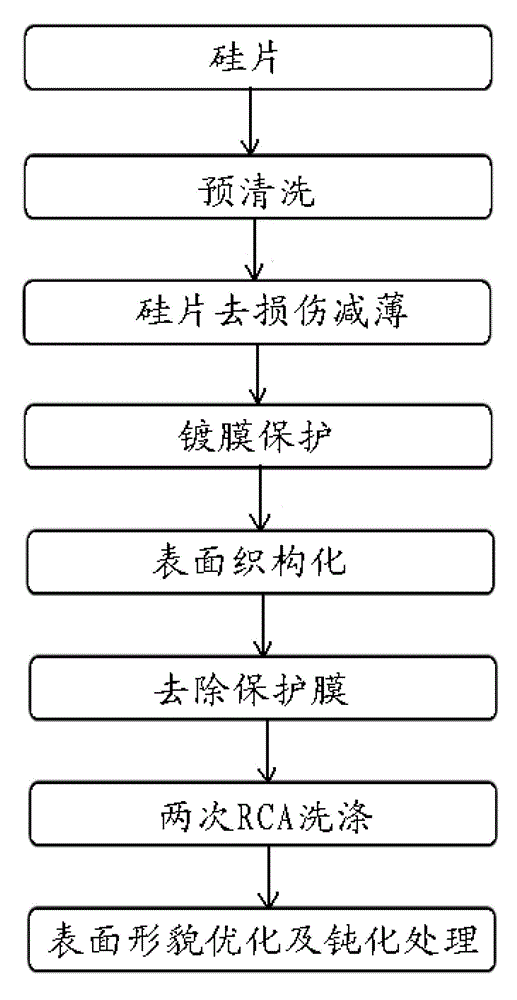

[0037] A surface wet treatment process for making high-efficiency crystalline silicon solar cells has the following steps:

[0038] (1) Pre-cleaning: Place the silicon wafer in absolute ethanol for ultrasonic cleaning, and then treat it with RCA solution and hydrofluoric acid to remove inorganic metal ions and organic particle pollutants.

[0039] The silicon wafer is placed in absolute ethanol for 10 minutes for ultrasonic cleaning, and the RCA solution has a volume ratio of DI:NH 4 OH:H 2 o 2 =4:1:1 solution, the RCA solution treatment temperature is 65-85°C, the treatment time is 5-20min, the hydrofluoric acid concentration is 5wt%, and the hydrofluoric acid immersion time is 2min.

[0040] After the above treatment, the inorganic metal ions and organic particle pollutants on the surface of the silicon wafer can be effectively removed.

[0041] (2) Damage and thinning of the silicon wafer: the mechanically damaged layer on the surface of the silicon wafer and the residua...

specific Embodiment 2

[0052] A surface wet treatment process for making high-efficiency crystalline silicon solar cells has the following steps:

[0053] (1) Pre-cleaning: Place the silicon wafer in absolute ethanol for ultrasonic cleaning, and then treat it with RCA solution and hydrofluoric acid to remove inorganic metal ions and organic particle pollutants.

[0054] The silicon wafer is placed in absolute ethanol for 10 minutes for ultrasonic cleaning, and the RCA solution has a volume ratio of DI:NH 4 OH:H 2 o 2 =4:1:1 solution, the RCA solution treatment temperature is 65-85°C, the treatment time is 5-20min, the hydrofluoric acid concentration is 5wt%, and the hydrofluoric acid immersion time is 2min.

[0055] After the above treatment, the inorganic metal ions and organic particle pollutants on the surface of the silicon wafer can be effectively removed.

[0056] (2) Damage and thinning of the silicon wafer: the mechanically damaged layer on the surface of the silicon wafer and the residua...

specific Embodiment 3

[0067] A surface wet treatment process for making high-efficiency crystalline silicon solar cells has the following steps:

[0068] (1) Pre-cleaning: Place the silicon wafer in absolute ethanol for ultrasonic cleaning, and then treat it with RCA solution and hydrofluoric acid to remove inorganic metal ions and organic particle pollutants.

[0069] The silicon wafer is placed in absolute ethanol for 10 minutes for ultrasonic cleaning, and the RCA solution has a volume ratio of DI:NH 4 OH:H 2 o 2 =4:1:1 solution, the RCA solution treatment temperature is 65-85°C, the treatment time is 5-20min, the hydrofluoric acid concentration is 2.5wt%, and the hydrofluoric acid immersion time is 2min.

[0070] After the above treatment, the inorganic metal ions and organic particle pollutants on the surface of the silicon wafer can be effectively removed.

[0071] (2) Damage and thinning of the silicon wafer: the mechanically damaged layer on the surface of the silicon wafer and the resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com