Bromine carbon alkyd resin fireproof enamel and its preparation method

A technology of bromocarbon alkyd and brominated epoxy resin, which is applied in the direction of fireproof coatings, magnetic coatings, coatings, etc., can solve the problems of coating performance degradation, increase equipment or furniture maintenance costs, shorten the service life of coatings, etc., and achieve improvement The effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

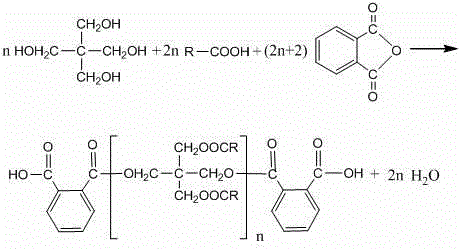

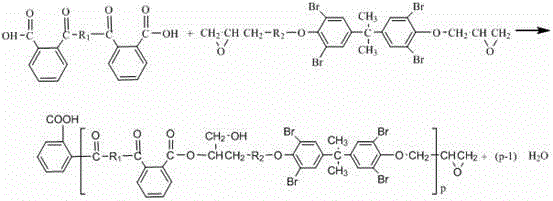

[0033] The preparation steps of bromocarbon alkyd resin are:

[0034] In a 500ml four-neck flask equipped with a stirring device, an oil-water separator and a thermometer, add soyoleic acid, pentaerythritol, and phthalic anhydride in sequence according to the formula, protect with nitrogen, start stirring and condense water, and add the formula when the temperature rises to 120°C amount of catalyst lithium hydroxide and xylene, and continue to heat up to 180°C, start heat preservation, the heat preservation process is 50~60min; after the heat preservation stage is over, add brominated epoxy resin according to the formula, so that the temperature is controlled at 180°C~200 ℃, the reaction time is 90 minutes to 120 minutes, when the acid value is within 10mgKOH / g, the reaction can be stopped, the temperature is lowered to 180 ℃, the water and xylene in the oil-water separator are released, and the amount of nitrogen is increased to release the bromine The xylene in the carbon al...

Embodiment 1

[0040] Embodiment 1. The preparation of bromocarbon alkyd resin

[0041] In a 500ml four-neck flask equipped with a stirring device, an oil-water separator and a thermometer, add 60 parts of soy oil, 10 parts of pentaerythritol, and 10 parts of phthalic anhydride in sequence by mass parts, pass nitrogen protection, start stirring and condensing water, and heat up Add 0.02 parts of catalyst lithium hydroxide and 4.98 parts of xylene at 120 ° C, and continue to heat up to 180 ° C, start the heat preservation process, the heat preservation process is 50~60min; after the heat preservation stage, add 15 parts of brominated epoxy resin to control the temperature Between 180°C and 200°C, the reaction time is 90 minutes to 120 minutes. When the acid value is within 10mgKOH / g, the reaction can be stopped, the temperature is lowered to 180°C, and the water and xylene in the oil-water separator are released. Distill the xylene in the bromocarbon alkyd resin with nitrogen gas; lower the t...

Embodiment 2

[0042] Embodiment 2. Preparation of drier

[0043] In 100g200# solvent oil, add 5.5g cobalt isooctanoate, 22.2g manganese isooctanoate, 22.2g zirconium isooctanoate, and disperse at high speed for 2 hours under the condition of 3500r / mim to get bromocarbon alkyd resin facing type fireproof coating catalyst dry agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com