Metal substrate vertical GaN-based LED (Light-Emitting Diode) chip and manufacturing method thereof

A technology for LED chips and metal substrates, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve problems such as high deposition temperature, high preparation cost, and difficulty in growing high indium components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

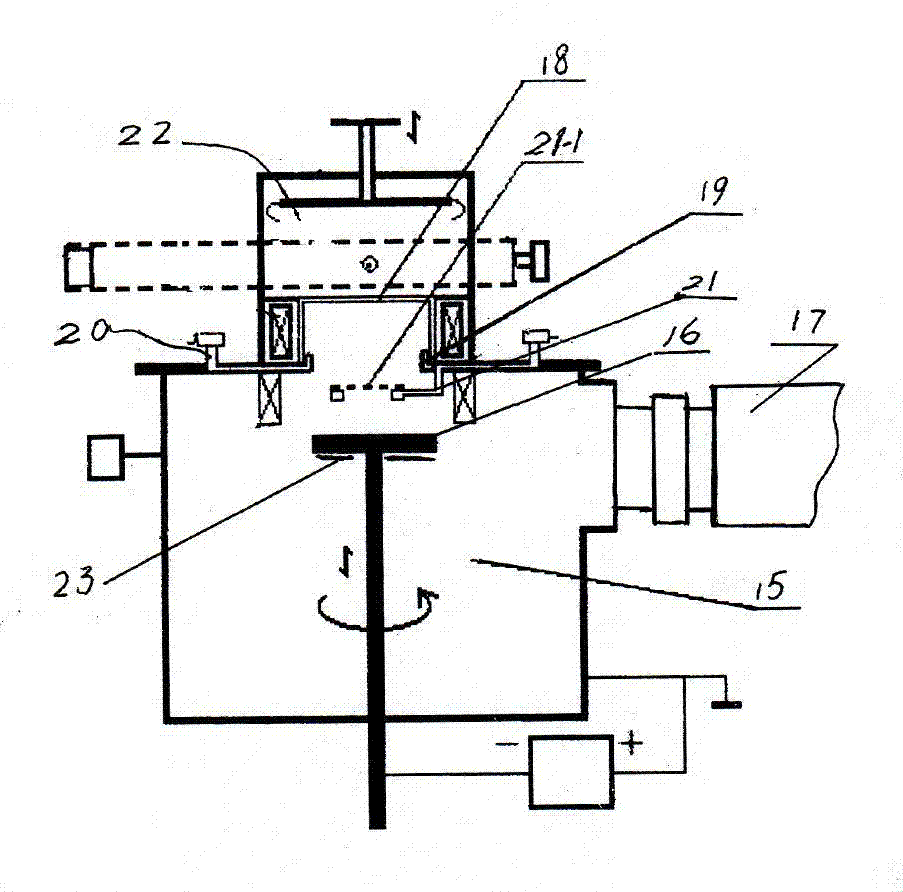

[0073] The second specific implementation mode, as attached figure 1 shown.

[0074] A vertical GaN-based LED chip, including an aluminum substrate (1) with a thickness of 0.5mm, and on one side of the metal aluminum substrate (1), Al x Ga y In 1-x-yN buffer layer (2), undoped Al x Ga y In 1-x-y N layer (3), n-type doped Al x Ga y In 1-x-y N layer (4), In x Ga 1-x N / GaN multiple quantum well MQW layer (5), p-type doped Al x Ga 1-x N layer (6), p-type doped Al x Ga y In 1-x-y N layer(7), n + heavily doped Al x Ga y In 1-x-y N layer (8), indium tin oxide ITO layer (9); Ni / Au electrode layer (10) is arranged on the surface of indium tin oxide ITO layer (9).

[0075] Specific Embodiment 2 The LED chip is prepared using the process steps of Specific Embodiment 1; the chip size is 300 μm×300 μm, when the applied voltage is 3.2V, its luminous wavelength is 515nm, and its brightness is 200mcd. Aluminum substrate vertical GaN-based LED green chip.

[0076] By chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com