Austenitic stainless steel

A technology of austenitic stainless steel and stainless steel, applied in the field of stainless steel, can solve the problems of thermal strength and durability that need to be further strengthened, and achieve the effect of improving intergranular corrosion resistance, improving strength and high-temperature mechanical properties, and beautiful molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

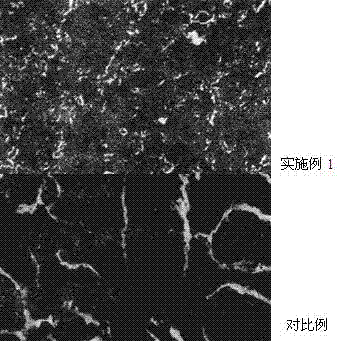

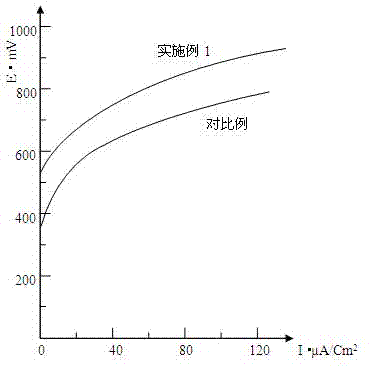

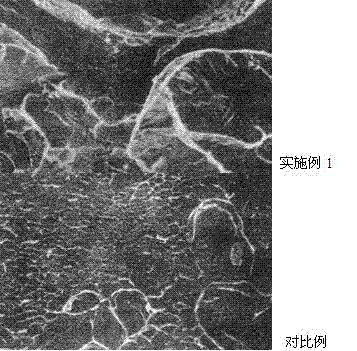

[0026] The test conditions of the intergranular corrosion tendency test of Example 1 and the comparative example are: the sample size is 10mm×10mm×5mm, and 1cm is left on the front side. 2 On the research surface, a wire with a plastic skin is welded on the back side, and the rest of the sample is inlaid with polystyrene. The oxalic acid electrolytic etching method in the "Test Method for Intergranular Corrosion Tendency of Stainless Acid-resistant Steel" is used to determine Test the tendency of intergranular corrosion of steel. by figure 1 It can be seen that there are some small etch pits on the etched surface of the stainless steel of Example 1, and the depth of the etch is not large, while the surface of the austenitic stainless steel of the comparative example has inter-etching pits along the boundary of the ferrite precipitate phase. The phenomenon of interconnection, that is, the formation of etch grooves, as a result, the intergranular corrosion resistance of the auste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com