Disposable medical equipment prepared from degradable substrate and method

A medical device, disposable technology, applied in the field of degradable substrates, to achieve the effect of saving electricity consumption, saving input costs, and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

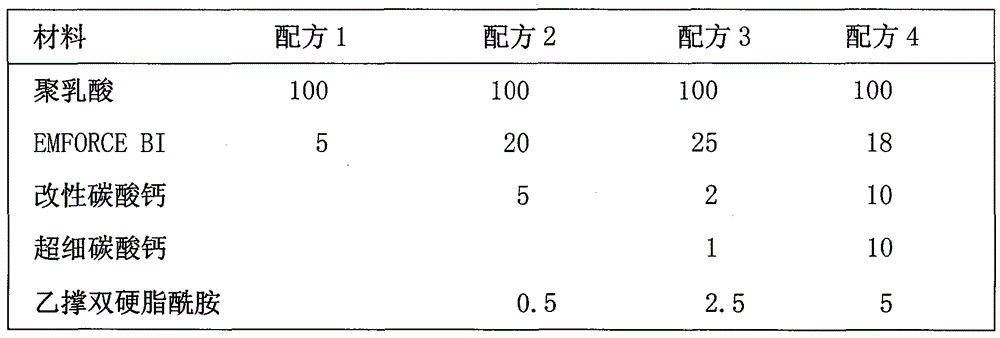

[0041] Embodiment 1 Injection molding method of degradable disposable fallopian tube extraction hook and extraction plate, disposable tweezers, disposable uterine probe, two-way and three-way valve of disposable infusion set:

[0042] The first step, vacuum drying: the degradable substrate pellets of formula 1 were vacuum-dried at 50° C. for 3 hours, and then used.

[0043] The second step, injection molding: add the dried degradable substrate pellets of Formula 1 to an injection molding machine for injection molding.

[0044] The barrel temperature is set as: feed inlet 155°C, compression section 160°C, metering section 165°C, nozzle 155°C;

[0045] Mold temperature: 15°C;

[0046] Injection pressure: 50-70Mpa;

[0047] Injection molding cycle: 41 seconds;

[0048] The holding time is: 0 seconds;

[0049] The screw speed is: 180 rpm;

[0050] Disposable medical instruments such as degradable disposable fallopian tube extraction hook and extraction plate, disposable tweez...

Embodiment 2

[0051] Example 2 Disposable oral cavity impression tray, disposable tongue depressor, disposable oral mirror handle, disposable otoscope, disposable titanium holder, flushing head of disposable flushing device, disposable infusion set dosing device, Injection molding method of disposable infusion set clips and disposable injection needle blades:

[0052] The first step, vacuum drying: the degradable substrate pellets of formula 2 were vacuum-dried at 50° C. for 3 hours, and then used.

[0053] The second step, injection molding: add the dried formula 2 degradable substrate pellets to the injection molding machine for injection molding.

[0054] The barrel temperature is set as: feed inlet 160°C, compression section 165°C, metering section 170°C, nozzle 170°C;

[0055] Mold temperature: 15°C;

[0056] Injection pressure: 50-95Mpa;

[0057] Injection time: 43 seconds;

[0058] The holding time is: 0 seconds;

[0059] The screw speed is: 180 rpm.

[0060]Disposable medical ...

Embodiment 4

[0061] Embodiment 4 Disposable vaginal dilator, disposable cervical dilator, disposable blood vessel clamp, disposable mouthpiece, disposable breathing filter, disposable oropharyngeal airway, disposable anesthesia laryngoscope, disposable rhinoscope , Disposable bone nails, disposable umbilical cord clips, disposable nasopharyngeal biopsy forceps, disposable rectal and sigmoid colon biopsy forceps, and injection molding methods for disposable infusion set needles:

[0062] The first step, vacuum drying: the degradable substrate pellets of formula 4 were vacuum-dried at 50° C. for 3 hours, and then used.

[0063] The second step, injection molding: add the dried formula 4 degradable substrate pellets to the injection molding machine for injection molding.

[0064] The barrel temperature is set as: feed inlet 160°C, compression section 165°C, metering section 170°C, nozzle 175°C; mold temperature: 20°C;

[0065] Injection pressure: 50-100Mpa;

[0066] Injection cycle: 45 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com