Star polymer used as lubricating oil viscosity index improver, preparation method and application thereof

A star-shaped polymer and lubricating oil composition technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problem of viscosity increasing effect, namely viscosity index, shear stability, i.e. viscosity loss value, low temperature performance is not significantly improved, Low temperature cold start viscosity and low temperature pumping performance are not significantly improved, viscosity loss and low temperature cold start performance are not significantly improved, etc., to achieve excellent viscosity increasing effect, excellent shear stability, low temperature pumping performance and low temperature start performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

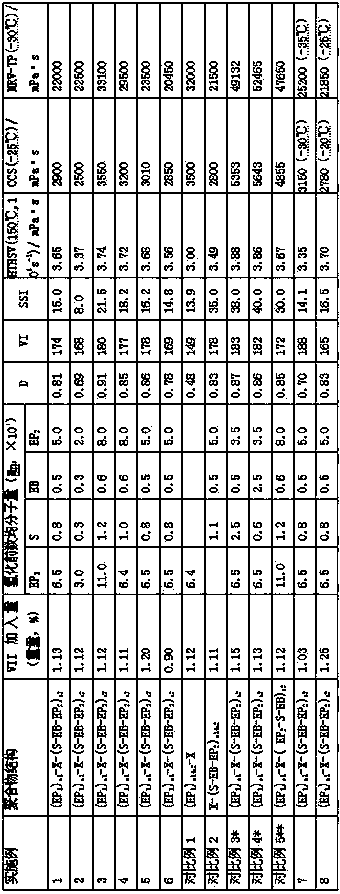

Examples

Embodiment 1

[0043] In this example, a star polymer with polystyrene block, hydrogenated isoprene block and hydrogenated butadiene block is prepared, the structure of which is (EP 1 ) n1 -X-(S-EB-EP 2 ) n2 , wherein the polymer solution concentration is 10% by weight. Polymer preparation methods include:

[0044] 1) Add 2250g of cyclohexane and 250g of isoprene into the 5L jacketed Reactor A that has been fully replaced by purified nitrogen, heat to 60°C, and then add 7.69mL of 0.5M normal The butyllithium cyclohexane solution was reacted for 60 minutes, and the maximum temperature during the polymerization reaction did not exceed 90°C to obtain an active polyisoprene block (I1-Li). After the isoprene polymerization was completed, the active polyisoprene The number average molecular weight (Mn) of the block (I1-Li) is 65000;

[0045] 2) Add 2,835g of cyclohexane and 250g of isoprene to a 10L jacketed reactor B that has been fully replaced with refined nitrogen, heat to 60°C, and add 1...

Embodiment 2

[0054] Basically repeat Example 1, except that the initiator for polymerization is sec-butyllithium, the starting temperature of the polymerization reaction in step 1) is 40°C, the reaction time is 120 minutes, the maximum temperature in the reaction process does not exceed 70°C, and the molecular weight of EP1 before hydrogenation is 30000; the initial temperature of the polymerization reaction of the isoprene segment in step (2) is 40°C, the reaction time is 120 minutes, the reaction time after adding butadiene and styrene is 120 minutes, and the maximum temperature during the reaction is not Over 80°C, the molecular weight of EP2 before hydrogenation is 20,000, the molecular weight of EB before hydrogenation is 3,000, the 1,4-structure content of polybutadiene block (B) is 88%, and the molecular weight of S is 3,000. The amount of divinylbenzene added was 4 moles of divinylbenzene per mole of active polymer. The catalyst used for hydrogenation is a mixture of nickel naphthe...

Embodiment 3

[0056] Basically repeat Example 1, except that the solvent for polymerization is n-hexane, the starting temperature of the polymerization reaction in step (1) is 70°C, the reaction time is 30 minutes, the maximum temperature during the reaction process does not exceed 110°C, and the molecular weight of EP1 before hydrogenation is 110,000 ; The initial temperature of the polymerization reaction of the isoprene segment in step (2) is 70°C, the reaction time is 30 minutes, the reaction time after adding butadiene and styrene is 60 minutes, and the maximum temperature during the reaction does not exceed 110 °C, the molecular weight of EP2 before hydrogenation was 80,000, the molecular weight of EB before hydrogenation was 6,000, the 1,4-structure content of the polybutadiene block (B) was 92%, and the molecular weight of S was 12,000. The catalyst used for hydrogenation is a mixture of nickel octoate and triisobutylaluminum, in which the molar ratio of Al / Ni is 6:1, the amount of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com