Washable anti-aging carboxy styrene-butadiene latex for carpet back coating as well as preparation method and application of latex

A technology of carboxylated styrene-butadiene latex and emulsifier, which is applied in the directions of coatings, adhesives, textiles and paper making, etc., can solve the problem of latex aging control and the control method of product washing resistance, not mentioned anionic emulsifier and other problems, to achieve the effect of good water resistance and good thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

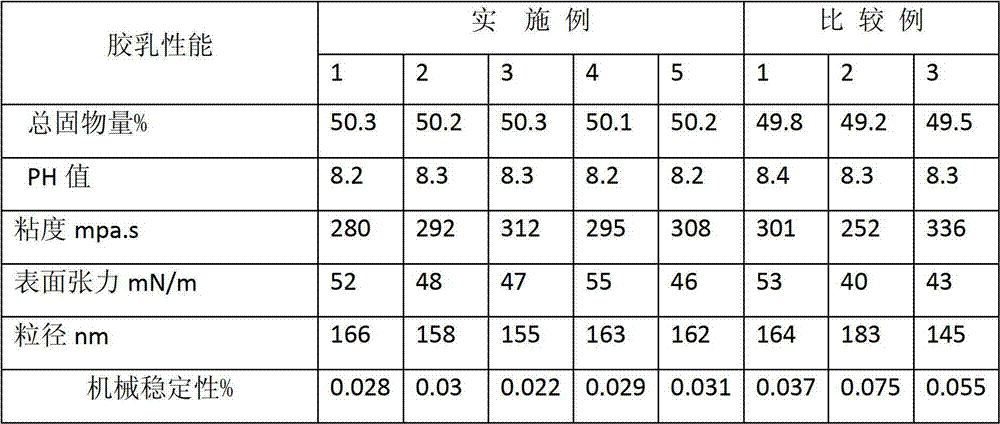

Examples

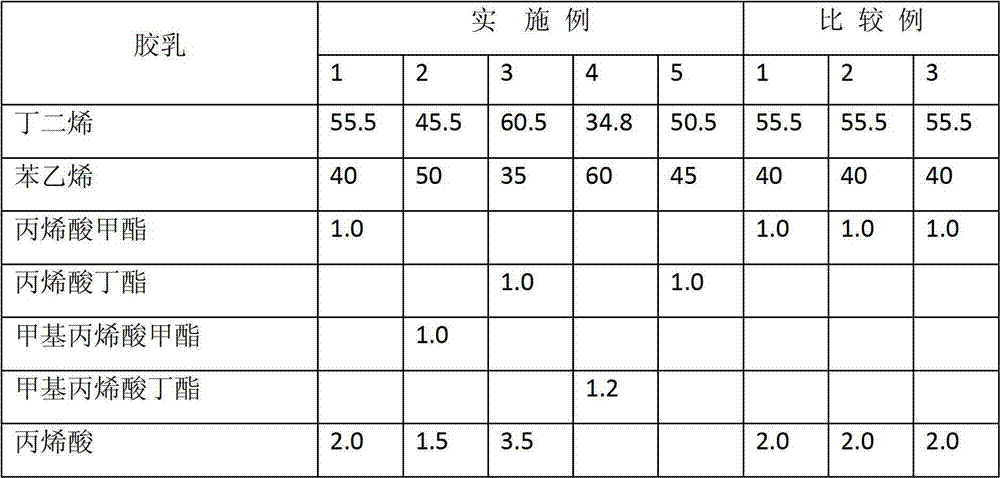

Embodiment 1

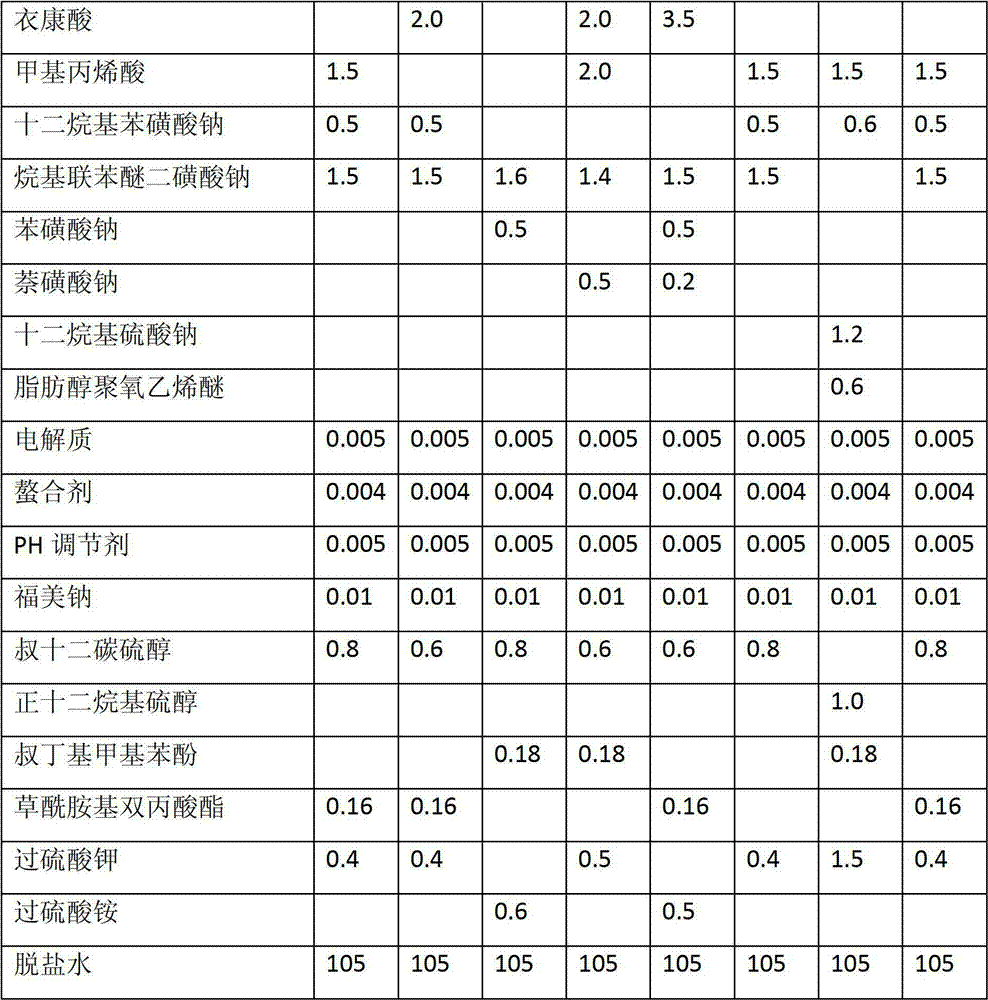

[0025] 55.5 parts of main monomer butadiene, 40 parts of styrene; 1 part of auxiliary monomer methyl acrylate; 2 parts of functional monomer acrylic acid, 1.5 parts of methacrylic acid; anionic emulsifier 1.5 parts of sodium alkyl diphenyl ether disulfonate 0.5 parts of sodium dodecylbenzenesulfonate; 0.8 parts of molecular weight regulator tertiary dodecyl mercaptan; 0.16 parts of reactive anti-aging agent oxalamidodipropionate; 0.005 parts of electrolyte NaCl, chelating agent EDTA-2Na0 .004 parts, PH regulator NaHCO 3 0.005 parts, 0.01 parts of sodium thiram; 0.4 parts of thermal decomposition type initiator potassium persulfate, about 105 parts of desalted water.

[0026] Under vacuum, add an emulsifier aqueous solution (1.5 parts of sodium alkyl diphenyl ether disulfonate; all electrolytes, chelating agents, pH regulators; 12 parts of desalinated water), 76 parts of desalinated water, styrene 40 parts, 1 part of methyl acrylate, 0.16 parts of oxalamidodipropionate, 2 parts ...

Embodiment 2

[0028] Main monomer butadiene 45.5 parts, styrene 50 parts; auxiliary monomer methyl methacrylate 1 part; functional monomer acrylic acid 1.5 parts, itaconic acid 2.0 parts; anionic emulsifier alkyl diphenyl ether disulfonic acid 1.5 parts of sodium, 0.5 parts of sodium dodecylbenzenesulfonate; 0.6 parts of molecular weight regulator tertiary dodecyl mercaptan; 0.16 parts of reactive antioxidant oxalamidodipropionate; 0.005 parts of electrolyte NaCl, chelating agent EDTA -4Na 0.004 parts, PH regulator Na 2 CO 3 0.005 parts, 0.01 parts of thiram sodium; 0.4 parts of thermal decomposition type initiator potassium persulfate, and 105 parts of desalted water by weight.

[0029] Under vacuum, add an emulsifier aqueous solution (1.5 parts of sodium alkyl diphenyl ether disulfonate; all electrolytes, chelating agents, pH regulators; 12 parts of desalinated water), 76 parts of desalinated water, styrene 50 parts, 1 part of methyl methacrylate, 0.16 parts of oxalamidodipropionate, 1....

Embodiment 3

[0031] 60.5 parts of main monomer butadiene, 35 parts of styrene; 1 part of auxiliary monomer butyl acrylate; 3.5 parts of functional monomer acrylic acid; 1.6 parts of anionic emulsifier sodium alkyl diphenyl ether disulfonate, sodium benzenesulfonate 0.5 parts; 0.8 parts of molecular weight regulator tert-dodecyl mercaptan; 0.18 parts of reactive anti-aging agent tert-butylmethylphenol; 0.005 parts of electrolytic NaCl, 0.004 parts of chelating agent EDTA-2Na, pH regulator Na 2 CO 3 0.005 parts, 0.01 parts of sodium thiram; 0.6 parts of thermal decomposition initiator ammonium persulfate, about 105 parts of desalted water.

[0032] Under vacuum, add an emulsifier aqueous solution (1.6 parts of sodium alkyl diphenyl ether disulfonate; all electrolytes, chelating agents, pH regulators; 12 parts of desalinated water), 76 parts of desalinated water, styrene 3.5 parts, 1 part of butyl acrylate, 0.18 parts of butyl methylphenol, 3.5 parts of acrylic acid, 0.8 parts of tertiary do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com