Anti-clogging method for heat exchanger and anti-clogging heat exchanger for acetonitrile purification

A technology of heat exchanger and acetonitrile, which is applied in the direction of heat exchanger shell, heat exchange equipment, cleaning heat transfer device, etc., which can solve the problems of increased safety risk, decreased equipment utilization rate, and easy Blockage and other problems, to achieve the effects of heat transfer, space saving, and impact force increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

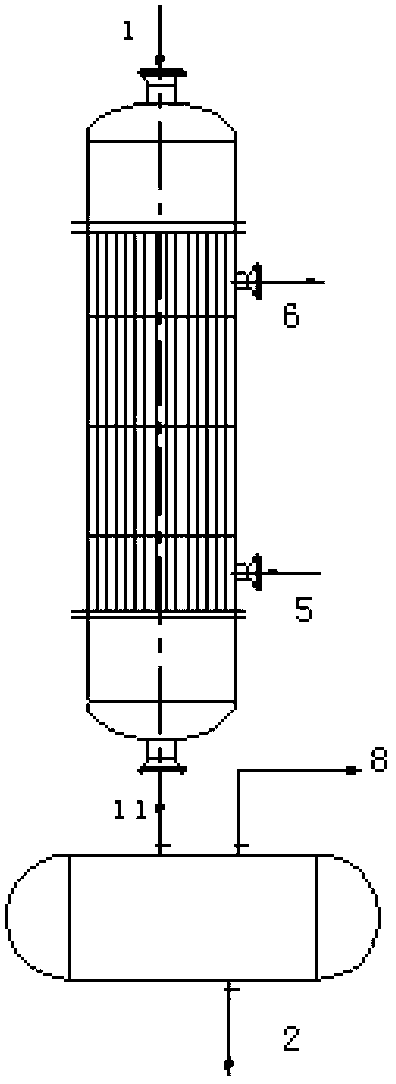

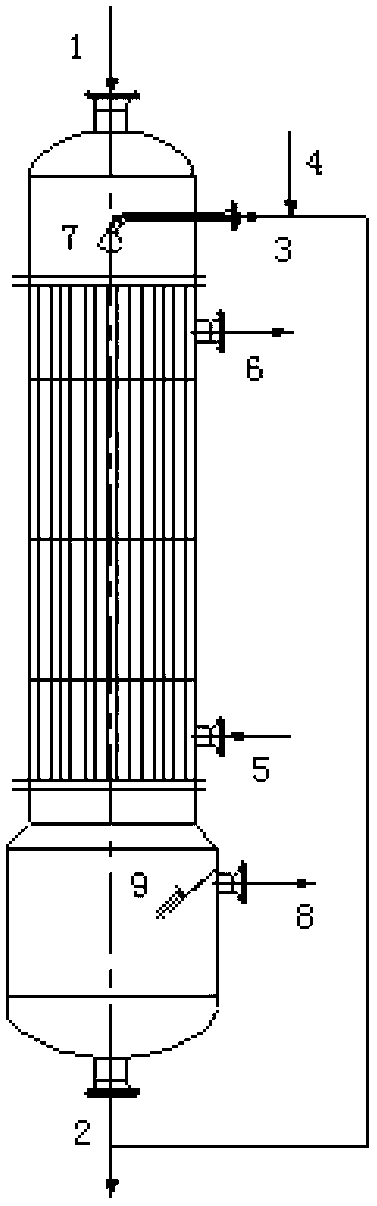

[0042] When crude acetonitrile enters the purification process of acetonitrile decyanation tower, use the present invention figure 2 , image 3 heat exchanger shown. Process materials enter from process material inlet 1, liquid phase material exits from 2 outlets, and gas phase materials exit from gas phase material outlets from 8; public engineering materials enter from 5 public engineering material inlets and public engineering material outlets 6.

[0043] The nozzle form of heat exchanger described in the present embodiment is as shown in table 1:

[0044] Table 1

[0045] The main parameters

parameter value

Nozzle form

Nominal diameter

600mm

Distance between nozzle and tube sheet

300mm

[0046]The process operating conditions are: the feed temperature of the tube-side fluid is 70-80°C, the outlet temperature is 61-71°C, the operating pressure is 0.001-0.009MPaG, and the condensed liquid phase mater...

Embodiment 2

[0050] When crude acetonitrile enters the purification process of acetonitrile decyanation tower, use the present invention figure 2 , image 3 heat exchanger shown. Process materials enter from process material inlet 1, liquid phase material exits from 2 outlets, and gas phase materials exit from gas phase material outlets from 8; public engineering materials enter from 5 public engineering material inlets and public engineering material outlets 6.

[0051] The heat exchanger described in this embodiment, the nozzle form is as shown in Table 2:

[0052] Table 2

[0053] The main parameters

parameter value

Nozzle form

Solid Cone Nozzle

Nominal diameter

500mm

Distance between nozzle and tube sheet

200mm

[0054] The process operating conditions are: the feed temperature of the tube-side fluid is 70-80°C, the outlet temperature is 61-71°C, the operating pressure is 0.001-0.009MPaG, and the condensed liquid phase material ...

Embodiment 3

[0058] When crude acetonitrile enters the purification process of acetonitrile decyanation tower, use the present invention figure 2 , image 3 heat exchanger shown. Process materials enter from process material inlet 1, liquid phase material exits from 2 outlets, and gas phase materials exit from gas phase material outlets from 8; public engineering materials enter from 5 public engineering material inlets and public engineering material outlets 6.

[0059] Heat exchanger described in the present embodiment, nozzle form is as shown in table 3:

[0060] table 3

[0061] The main parameters

parameter value

Nozzle form

Solid Cone Nozzle

Nominal diameter

450mm

Distance between nozzle and tube sheet

100mm

[0062] The process operating conditions are: the feed temperature of the tube-side fluid is 70-80°C, the outlet temperature is 61-71°C, the operating pressure is 0.001-0.009MPaG, and the condensed liquid phase material d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com