Beer production technology

A production process and technology of beer, which is applied in the field of chemical production process, can solve the problems of low cost, environmental pollution, environmental pollution, etc., and achieve the effects of reducing environmental impact, facilitating separation, and ensuring taste and aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of beer production technology of the present embodiment is characterized in that its processing steps are as follows:

[0020] (1) Raw material pretreatment: after soaking, germinating, drying and removing roots, the barley is sent to the crushing tower for crushing;

[0021] (2) Gelatinization and filtration: Heat and boil the crushed barley and water in the gelatinization pot to convert into soluble malt extract, that is, wort, and then send it to the separation tower for filtration;

[0022] (3) Sewage treatment: After gelatinization and filtration, the sewage from the washing gelatinization pot and separation tower is concentrated in the sewage pool through pipelines, and then processed by UASB+CASS, and the obtained water is used for industry and agriculture;

[0023] (4) Boiling: Boil the wort obtained in step (2), add water, add hops once for 10 minutes, 30 minutes and 10 minutes before the end of boiling. Its mass ratio is 70%: 30%;

[0024] (5) Precipi...

Embodiment 2

[0028] The rest are the same as in Example 1, except that the temperature in step (6) is controlled at 10°C, the fermentation time is 9 days, the time in step (7) is controlled at 15 days, and in step (2), the A paddle-type agitator is arranged at the bottom of the gelatinization pot, and the hops in step (4) are bitter granular hops and aroma and granular hops, and the mass ratio thereof is 65%:35%.

Embodiment 3

[0030] The rest are the same as in Example 1, except that the temperature in step (6) is controlled at 15°C, the fermentation time is 8 days, and the time in step (7) is controlled at 21 days. In step (6), the Saccharomyces cerevisiae is the bottom yeast, and the hops in the step (4) are bitter granular hops and aroma and granular hops, the mass ratio of which is 80%:20%.

[0031]

[0032]

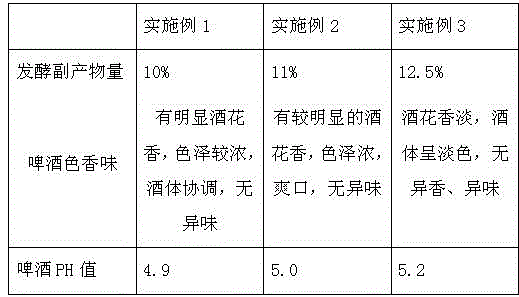

[0033] Through the above three examples, there are three sets of data in the above table. It can be seen that when the fermentation temperature is controlled at 7°C and the fermentation time is 10 days, the amount of by-products of fermentation is the least, the taste is good, and the hops are bitter granular hops and aroma and Granular hops, its mass ratio is 70%: 30%, when the maturation time is controlled at 15 days, the beer is fragrant and mellow, and the visual effect is better, so embodiment 2 is the best embodiment.

[0034] The present invention completes the production of bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com