Built-in heat pipe dual-medium heat transfer pipe

A dual medium, heat transfer tube technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as insufficient reliability, and achieve the effect of ensuring heat transfer capacity and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

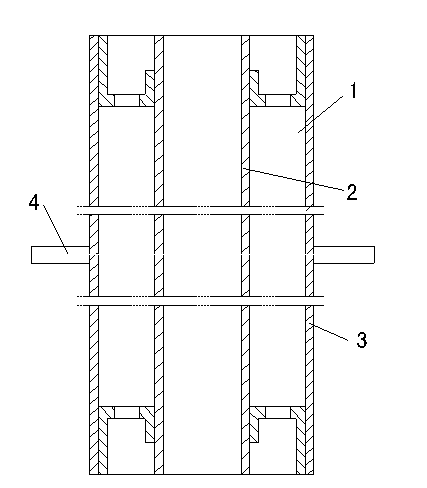

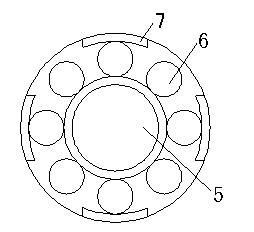

[0012] Such as figure 1 As shown, the dual-medium heat transfer tube with built-in heat pipe of the present invention includes a heat pipe 2 and a sleeve 3 , and the heat pipe 2 is installed in the sleeve 3 through a bracket 1 . The heat pipe 2 and the sleeve pipe 3 are concentric (the axis of the two coincides), so that the distribution of the medium can be even when flowing. Bracket 1 can be used as figure 2 In the structure shown, the bracket 1 is provided with uniform heat pipe installation holes 5 and working fluid channels 6 , the heat pipe installation holes 5 are located in the middle of the bracket 1 , and the working fluid channels 6 are evenly distributed on the periphery of the heat pipe installation holes 5 . A connecting block 7 is arranged on the outside of the bracket 1 , and the bracket 1 is fixed on the end of the casing 3 through the connecting block 7 . The bracket 1 can also adopt a star shape with a heat pipe installation hole 5 in the middle, or other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com