Seamless steel pipe with excellent hydrogen sulfide stress corrosion resistance and manufacture method thereof

A stress corrosion and hydrogen sulfide resistance technology, applied in rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problem of unreported hardness steel pipe residual stress value, microstructure grain size, and SSC resistance performance stability is difficult to guarantee, etc. problems, to achieve the effect of improving the resistance to hydrogen sulfide stress corrosion and stability, excellent resistance to hydrogen sulfide stress corrosion, and fine structure of the steel pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment the present invention is further described:

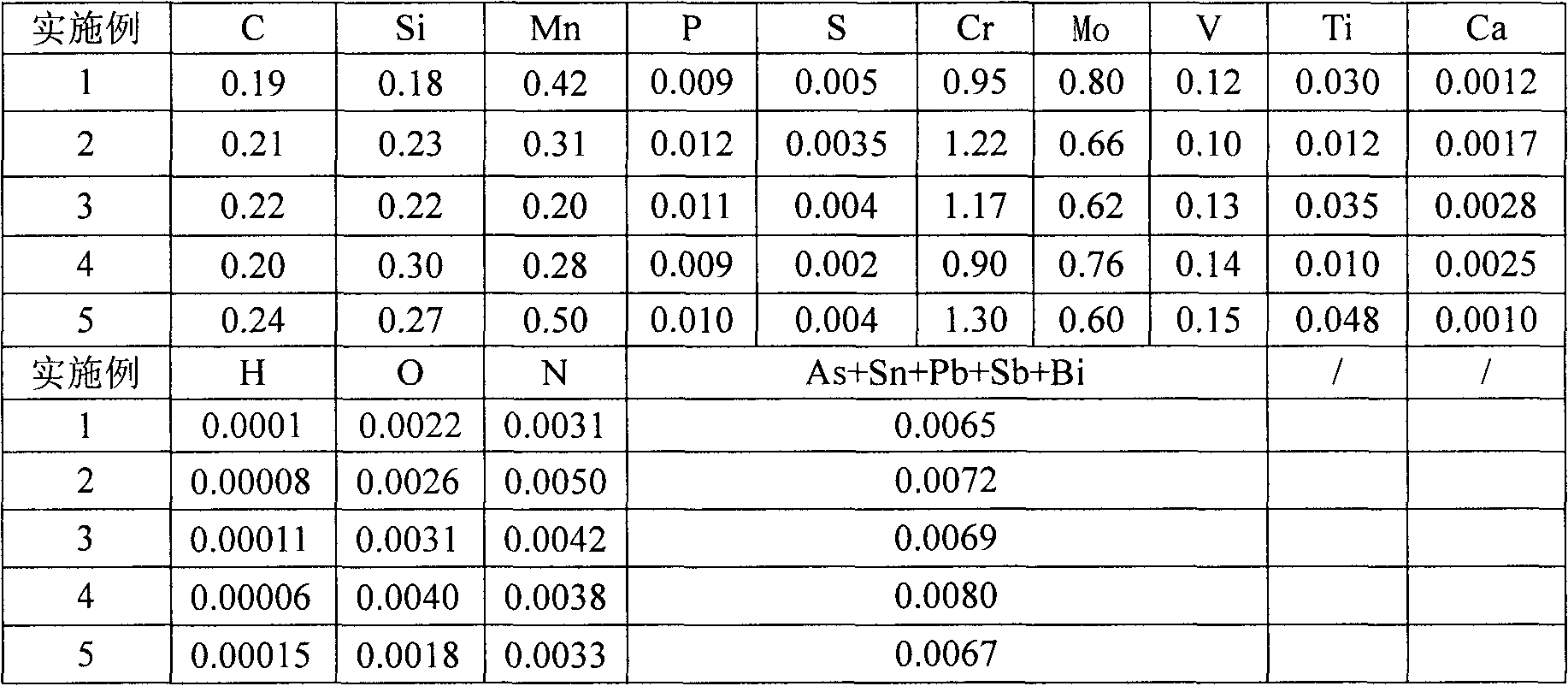

[0029] The chemical composition of specific embodiments of the present invention is shown in Table 1.

[0030] Chemical composition wt% of each embodiment of table 1

[0031]

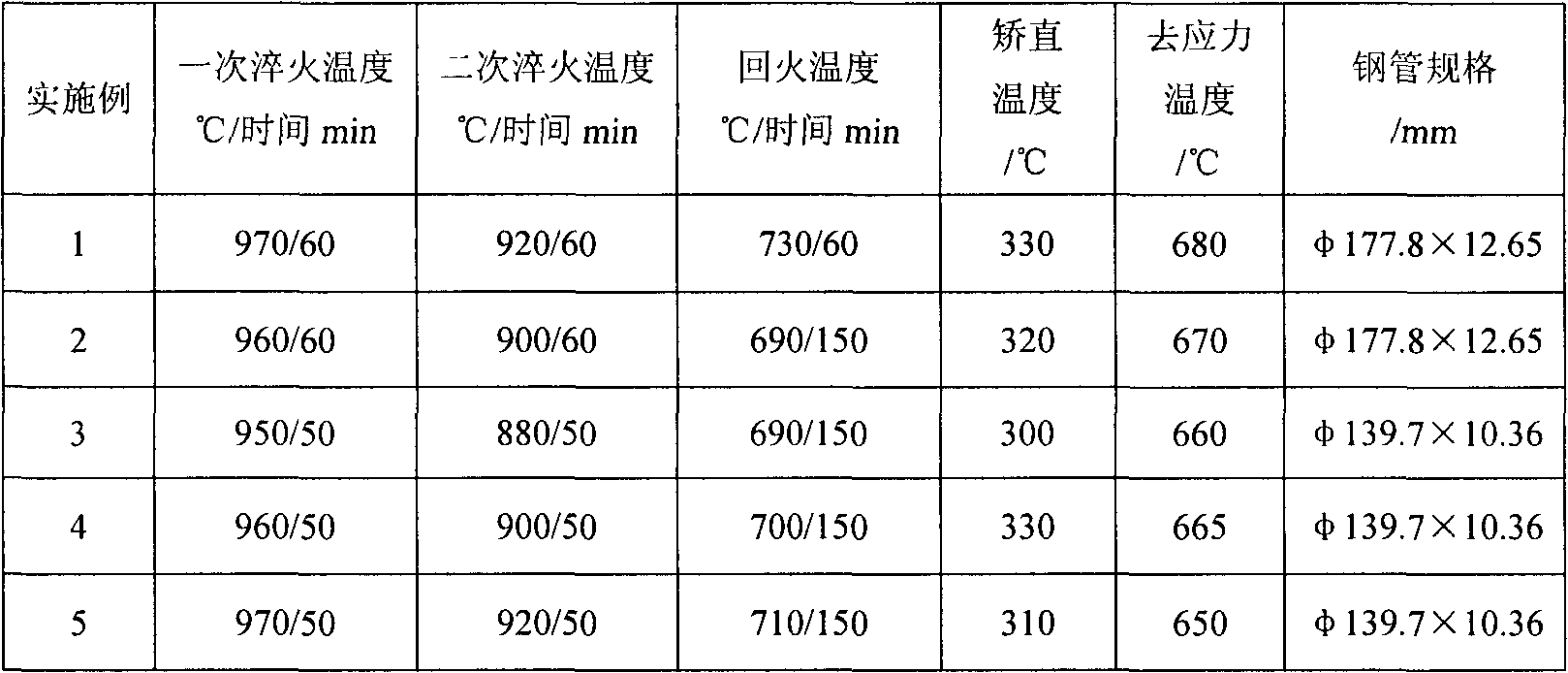

[0032] The low-alloy steel casting temperature of each composition combination in Table 1 is 1540-1560°C, the heating temperature of the billet hot charging for manufacturing the round pipe billet is 1240-1290°C, the billet rolling temperature is 1100-1150°C, and the hot continuous rolling temperature for pipe making is 1100- 1150°C, the final rolling temperature of the tube is 900-1050°C, the final rolled steel pipe is cooled by air cooling with a cooling rate greater than 1°C / s, and the φ177.8×12.65mm, φ139.7×10.36mm seamless steel pipe for oil well pipe is produced , through the heat treatment process in Table 2, the mechanical properties, residual stress, and SSC resistance performance in Table 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com