CuNiSiMg alloy material and preparation method thereof as well as method for preparing strip using alloy material

A technology of alloy materials and strips, which is applied in the preparation of strips from the alloy materials, CuNiSiMg alloy materials and its preparation fields, can solve problems such as dependence on imports, restricting the development of the electronic information industry, and unrealized industrialized production, so as to improve production efficiency , good shape and surface quality, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

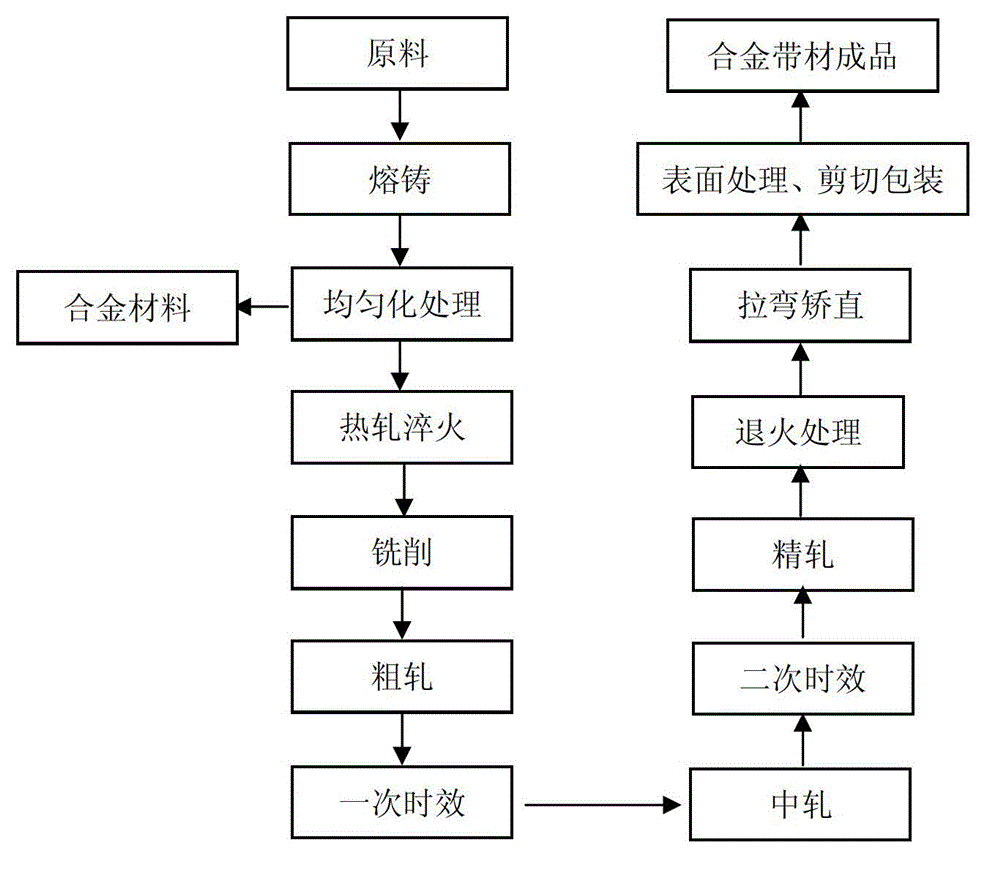

Method used

Image

Examples

Embodiment 1

[0034] Put 95.58 parts by weight of copper and 1.40 parts by weight of nickel into a melting furnace, heat to 1250 ° C ~ 1300 ° C to melt, spray charcoal carbon powder on the surface of the metal during the melting process to prevent the metal from being oxidized, and the furnace temperature drops to After 1150°C to 1200°C, add 2.54 parts by weight of copper-silicon alloy with 13% silicon content, 0.50 parts by weight of zinc, 0.45 parts by weight of copper-magnesium alloy with 18% magnesium content, and 0.36 parts by weight of copper-phosphorus with 10% phosphorus content. The alloy is stirred and melted evenly and cast into a 220×620×Lmm alloy ingot in a semi-continuous casting machine, and then the alloy ingot is heated and kept in a walking heating furnace, and the temperature of the heating furnace is controlled at 900°C to 920°C. The holding time is 3-4 hours to ensure that the dendrite segregation of the ingot is completely eliminated, the temperature difference of the i...

Embodiment 2

[0037] The cast ingot alloy in Example 1 is directly put into the two-roller reversible hot rolling mill for multi-pass back and forth hot rolling, the final rolling temperature is guaranteed to be above 650°C, and the final rolling is directly rolled to After 15mm, directly spray water on the hot rolling track to cool to about 60°C for coiling. After the hot-rolled coil is uncoiled, the upper and lower surfaces and two sides of the hot-rolled strip are simultaneously milled on a double-sided milling machine. The surface milling amount is 1 mm per side, and the side milling amount is 2 mm per side. Then roll. The milled coil is uncoiled, roughed in multiple passes on a reversing roughing mill, the thickness is rolled from 13.0mm to 4.8mm, and then coiled. Put the rough-rolled strip coil into a bell-type annealing furnace with a protective atmosphere for an aging treatment, keep it at 500°C for 6 hours, and then cool it naturally. Roll the strip after the primary aging treatm...

Embodiment 3

[0040] Put 95.09 parts by weight of copper and 1.80 parts by weight of nickel into a melting furnace, heat to 1250°C-1300°C to melt, spray charcoal carbon powder on the surface of the metal during the melting process to prevent the metal from being oxidized, and the furnace temperature drops to After 1150°C to 1200°C, add 2.53 parts by weight of copper-silicon alloy with 17% silicon content, 0.10 parts by weight of zinc, 0.28 parts by weight of copper-magnesium alloy with 22% magnesium content, and 0.20 parts by weight of copper-phosphorus with 14% phosphorus content. The alloy is stirred and melted evenly and cast into a 220×620×Lmm alloy ingot in a semi-continuous casting machine, and then the alloy ingot is heated and kept in a walking heating furnace, and the temperature of the heating furnace is controlled at 900°C to 920°C. The holding time is 3-4 hours to ensure that the dendrite segregation of the ingot is completely eliminated, the temperature difference of the ingot o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com