Adhesive with insulating and heat-conducting properties used at ultralow temperature

A kind of insulation and heat conduction, ultra-low temperature technology, used in adhesives, adhesive additives, epoxy resin glue and other directions, can solve the problem of thermal conductivity can not be applied to thermal conductivity and other problems, to achieve excellent thermal conductivity, ensure insulation performance, long storage period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

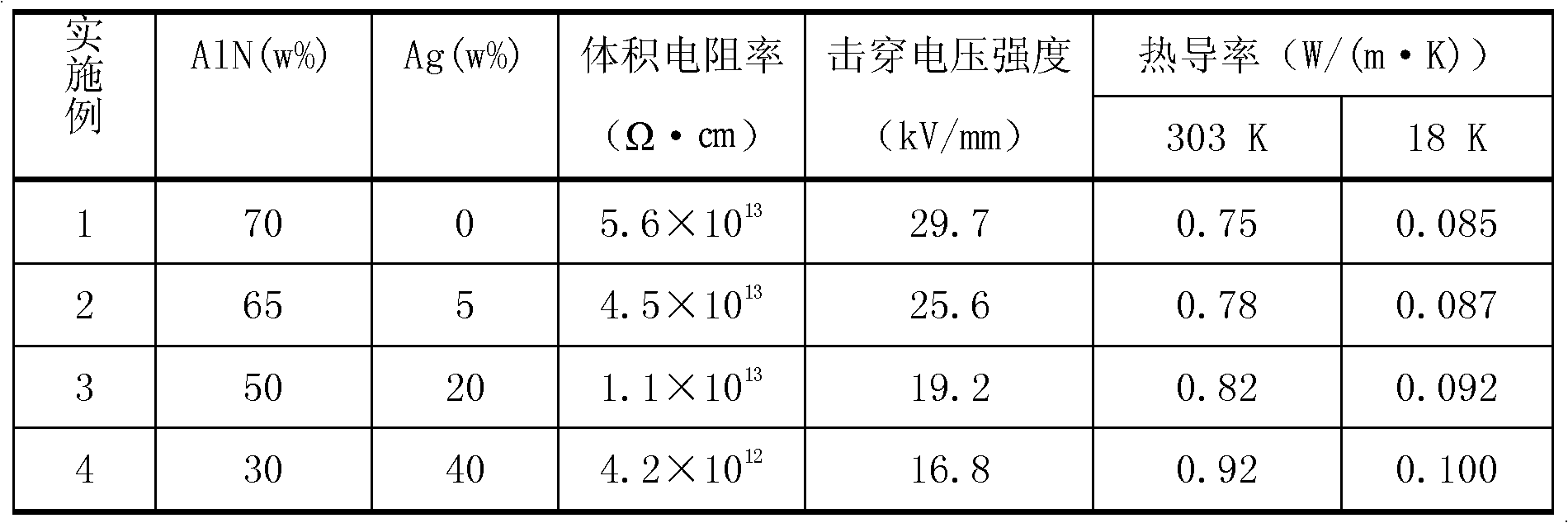

Embodiment 1

[0021] Weigh 100.0g of glycidyl ether type epoxy resin WSR 615 (bisphenol A), 6.0g of silane coupling agent KH-560 and 330.5g of micron-sized AlN powder, stir and mix with a glass rod, and then transfer the mixture to three rollers Grinder for mixing, after mixing evenly, add 28.3g of polyetheramine curing agent D-400 and 7.4g of aliphatic amine curing agent triethylenetetramine for curing reaction, to obtain the ultra-low temperature insulating heat-conducting adhesive of this embodiment; the carried out The curing conditions of the curing reaction are: heating at 25° C. for 24 hours, and then raising the temperature to 150° C. and heating for 6 hours.

Embodiment 2

[0023] Weigh 100.0g of glycidyl ether type epoxy resin WSR 615, 6.0g of silane coupling agent KH-560, 294.0g of micron-sized AlN particle powder and 22.615g of micron-sized Ag flakes, stir and mix with a glass rod, and then transfer the mixture Mix in a three-roll mill, and after mixing evenly, add 28.3g of polyetheramine curing agent D-400 and 7.4g of aliphatic amine curing agent triethylenetetramine for curing reaction to obtain the ultra-low temperature insulating and heat-conducting adhesive of this embodiment; The curing conditions of the curing reaction are: heating at 25° C. for 24 hours, and then raising the temperature to 150° C. and heating for 6 hours.

Embodiment 3

[0025] Weigh 100.0g of glycidyl ether type epoxy resin WSR 615, 6.0g of silane coupling agent KH-560, 226.2g of micron-sized AlN particle powder and 90.5g of micron-sized Ag flakes, stir and mix with a glass rod, and then transfer the mixture Mix in a three-roll mill, and after mixing evenly, add 28.3g of polyetheramine curing agent D-400 and 7.4g of aliphatic amine curing agent triethylenetetramine for curing reaction to obtain the ultra-low temperature insulating and heat-conducting adhesive of this embodiment; The curing conditions of the curing reaction are: heating at 25° C. for 24 hours, and then raising the temperature to 150° C. and heating for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com